Diamond saw blade is a tool that is widely used in stone cutting, but many times, people need to bring a lot of tools during on-site construction, such as saw blades with cutting, rough grinding discs with grinding, or directly use fine grinding blades, take that way, will not only increase consumption, but also cause slow efficiency. Therefore, many constructors hope that diamond saw blades can be used for both cutting and grinding, such as edging, slot milling, etc. Is there such a tool?

In fact, there is. Linxing Tools has long produced a tool that can be used for both cutting and grinding stone, and the name is called cutting and grinding disc. In the early days, this kind of cutting blade was mainly processed by electroplating. Electroplating is a way of using electroplating to fix the diamond on the saw blade substrate, so people distribute the diamond to the saw blade. The top of the blade and the surface of the saw blade can achieve the function of cutting and grinding. The most common types of electroplated discs are many, such as the Gypsophila series, which is the prototype of a very classic cutting blade.

However, due to process problems, the diamond usage rate of the electroplating disc is low. Due to the limited fixing capacity of electroplating, the holding force of diamond is weak. Once encountering a harder material, it will be consumed very quickly, and even grinding may not move. In addition, this saw blade consumes more diamonds, and is gradually eliminated by the market. At present, only a few customers are using this product.

Later, people hoped that the cold-pressed and sintered products could be made into cutting and grinding chips, which would greatly reduce the cost. However, this was not the case. Although the price of cold-pressed and sintered products was low, due to the process of sintering, the powder became nodules. It will lead to the liquid phase of the powder particles. After the solid phase is sintered, the entire segment will present a very smooth edge, which is very unfavorable for grinding. Especially if the powder is sintered on the surface of the saw blade through the liquid phase, the fixation becomes a huge problem. This method obviously cannot solve the problem of stone grinding. Therefore, for a long time, people cannot use the powder to directly sinter the substrate to complete the development and production of grinding discs.

In recent years, it has been found that the products produced by the vacuum brazing process are similar to the electroplating method. In this way, large particles of diamond can be fixed on the saw blade substrate, which can not only complete the cutting, but also in the grinding aspect. , If some diamonds are brazed on the outer arc parts on both sides of the sheet body, in the process of grinding, the diamonds quickly complete the grinding of the stone. More importantly, the diamond fixed in this way is more stable than the diamond in the electroplating process. What is more interesting is that it has been found that if the diamond is plated with titanium by a vacuum brazing machine, the strength of the diamond can be increased by about 20-30%. This discovery also makes the brazing diamond process more valuable for research.

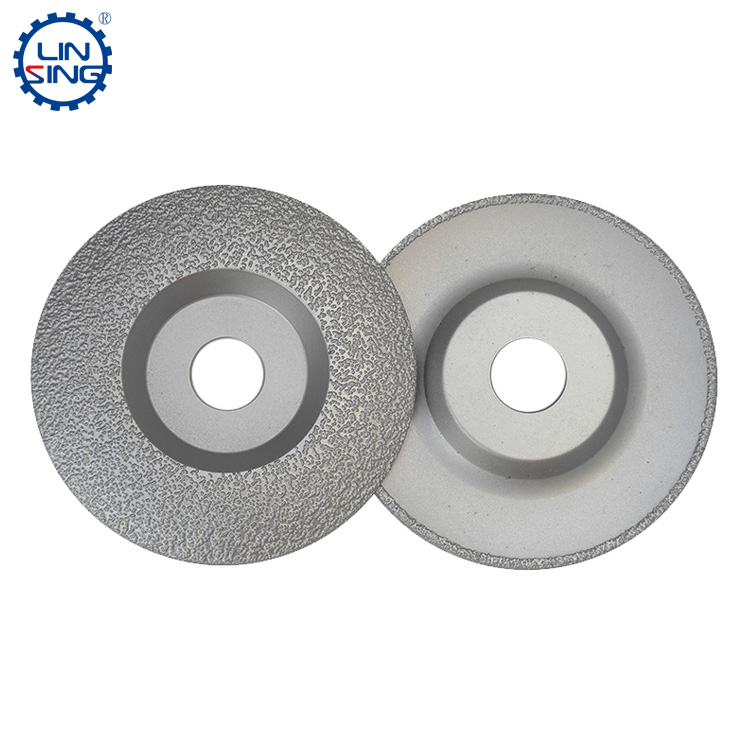

Brazed cutting and grinding wheel is the most practical diamond cutting and grinding saw blade at present. The main size is 100mm-250mm. Special specifications can be customized. It can be widely used for rapid cutting of marble and granite stone, edge cutting and plate surface grinding and stone surface of slotting and milling.

Diamond cutting and grinding saw blades

Publish date:2022-07-18 09:14:11 Article From:Linxing Diamond Tools Clicks: