Diamond saw blade is a common tool for cutting stone, and the process of stone cutting is actually a physical phenomenon of grinding. Through the harder diamond, intense friction occurs with the stone. During the friction process, according to the magnitude of the friction, part of the stone is ground off, and part of the diamond is also consumed. In the process of mutual friction, a lot of heat is generated, so most of the stone cutting process needs to continuously add coolant. Otherwise, it is easy to burn the segment and blank-blade of the diamond saw blade.

Stone grooving is a kind of stone processing technology. It mainly grooves the surface of the stone. It mainly plays the role of anti-slip, blind road, drainage, and can also play a role in aesthetics and artistic sense. In general, stone grooving is a kind of stone processing method created by modern people who have higher standards for daily life and make life more convenient.

The earliest application of stone grooving is the design of stone carving. People use chisels to continuously rub the surface of the stone to form grooves. This method is very labor-intensive. Especially in the ancient times with low technology, only large families would use this kind of grooved lines for home decoration, and there are many specific grooved objects, such as Yin carved ornaments, patterns of stone stools, line border patterns of stone monuments, and surface patterns of stone sinks ect.

The modern stone grooving process is much simpler, and there are mainly the following types of grooving methods:

1: Sandblasting and grooving, The sandblasting machine is mainly used to impact the slate at high speed through the emery, and the place not protected by the engraving paper will be constantly worn away, and the groove will appear when it is ground to a certain depth.

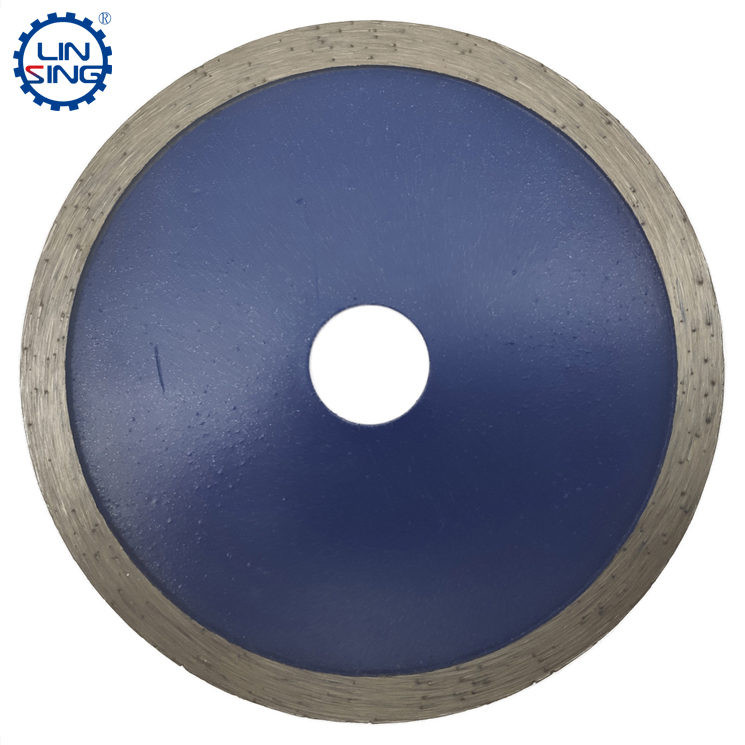

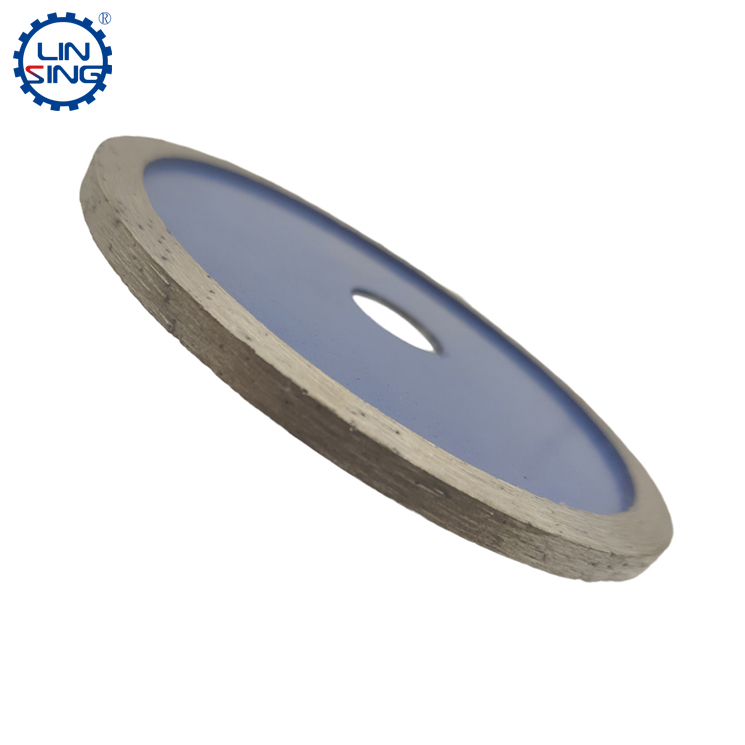

2: Manual slotting, Mainly use an electric cutting machine or an angle grinder, and quickly complete the cutting by a hand cutting machine. This kind of cutting is generally done with a small diameter diamond saw blade (50mm-150mm), and most of the grooves are square grooves or V-shaped grooves. The slotting method is the simplest, without the help of large machinery, However, the machining accuracy is often not high, and there will be uneven states. And in the case of a square groove, it is labor-intensive and time-consuming, and the bottom of the groove is uneven. This type of slotting is not used much. However, Linxing produces a slotted sheet with a diameter of 100-230mm. It adopts a continuous block design. The slot shape can be customized according to customer requirements, which greatly improves the efficiency of manual slotting. Customers can come to consult.

3: Professional slotting wheel, This tool mainly uses 4-axis or 5-axis infrared stone processing machinery to complete the grinding of the plate, This tool is fixed on the head of the cutting machine. Through rapid cutting, this type of grooved wheel is mainly divided into sintered segment type grooved wheel and vacuum brazed cutting and grinding wheel, both of which can be used for mining. The former pays more attention to life, and then are more focused on efficiency.

In general, diamond saw blades can be used for grooving, but to choose a more suitable grooving saw blade or grooving wheel, ordinary saw blades not only have low grooving efficiency, but also have many problems, so they are not recommended.

Can diamond saw blades be grooved?

Publish date:2022-07-18 09:05:49 Article From:Linxing Diamond Tools Clicks: