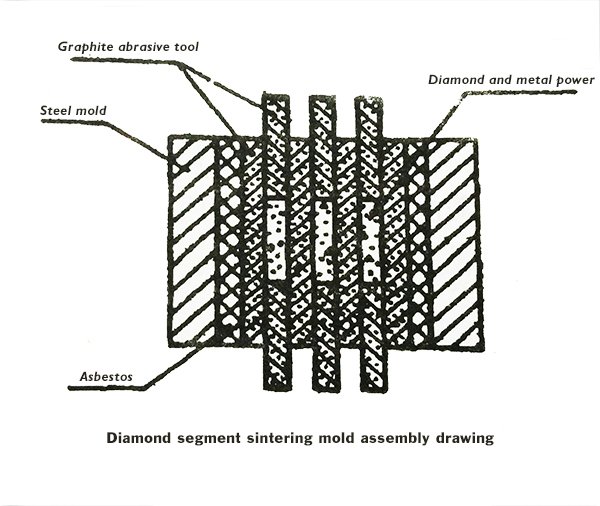

In the diamond segment production process, hot pressing sintering is the most important part, and the sintering press is the most commonly used and also the most common processing equipment used by segment manufacturers. This kind of machine is mainly energized, using the conductivity of the graphite abrasive tool and the segment itself, through the use of low voltage and high current, to quickly heat up the graphite abrasive tool and metal bond, and then give pressure through the outer steel mold, thereby The process of segment sintering is achieved. In this process, the metal bond, diamond powder and other materials in the segment make the overall structure stable through changes in physical and chemical properties, so as to prepare for later use on cutting tools.

At present, the tonnage and specifications of sintering presses at home and abroad are different, but their working principles are the same. They all use high current temperature rise and steel film pressure to perform the diamond segment sintering process. By introducing the diamond segment sintering process, we can better understand the working principle of the sintering press.

First of all, we need to mix the prepared diamond powder and bond material in the mixer. The mixed material, the material that needs to be cold pressed can be cold pressed first, and then the cold pressed segment is put into the graphite abrasive tool Medium; if the diamond segment of the cold pressing process is not required, the powder is directly loaded into the graphite abrasive tool according to a certain weight. In the graphite mill, during the electrification process, the motor on the sintering press applies a certain pressure to the die set through the hydraulic system in the upper and lower pressure heads with electrodes.

Secondly, when the powder is given to the mold, start to switch on the thermal power supply, passing low voltage (4-6V) and high current (usually set at several thousand amperes to 10,000 amperes). Because of the metal powder in the graphite abrasives and diamond segment raw materials, these materials have extremely low resistance. Through the calculation formula of heat, the square of the current is multiplied by the resistance, and then multiplied by the energization time. Under such high current, sintering The temperature also began to rise significantly, and finally reached the set temperature, through infrared temperature measurement technology, PC programmable controller intelligent temperature controller and other temperature controllers automatically adjust the real-time sintering temperature, so as to achieve the preset sintering Temperature and sintering time.

Then, when the temperature reaches 700-1000 degrees Celsius, the bond powder of the segment begins to melt, and then continue to increase the pressure so that the diamond powder and bond can be melted in the graphite abrasive tool, thereby producing a diamond segment of qualified quality. In this process, it is very necessary to choose a suitable press. For example, the pressure specifications of the press are: 15 tons, 20 tons, 100 tons, etc., and the heating power specifications are 20kVA, 50kVA, 60kVA, 100kVA, 120kVA, etc. The higher the pressure, the faster the temperature heating speed, which has a great influence on the production of better quality segments.

Finally, when the temperature and pressure reach a certain level, the temperature and pressure need to be reduced after heat preservation and pressure. After the final demolding, the entire diamond segment has completed the hot pressing sintering process.