Layers segment is also called multi-layer segment, which is different from non-layers segment. Most of the early segments were without layers. During the processing, diamond agglomerates were formed under a certain weight and pressure. However, the disadvantages of this segment are also very obvious, especially for the very high requirements of the formula, for example, the need for a formula The bond consumption in the medium is close to the consumption of diamonds, otherwise the segment cannot be cut from time to time.

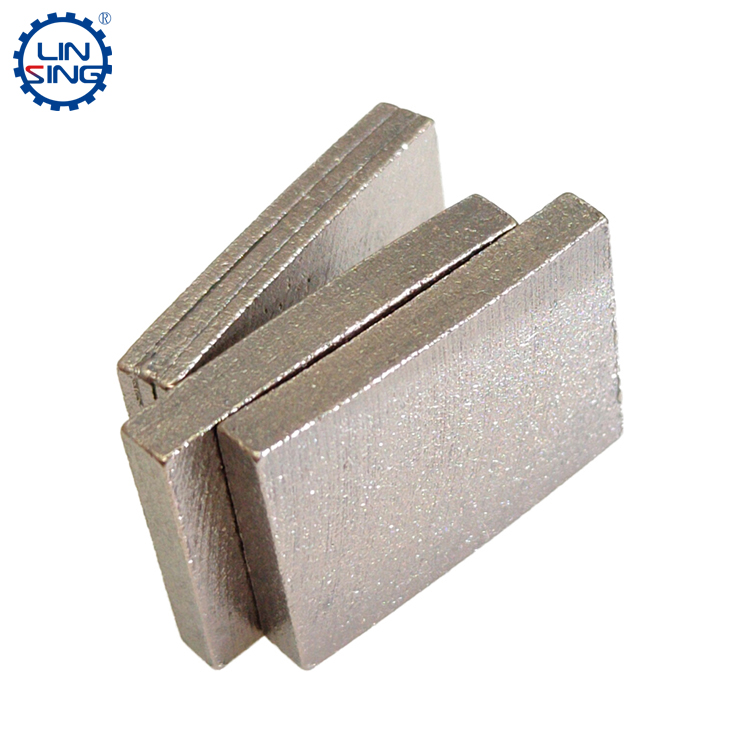

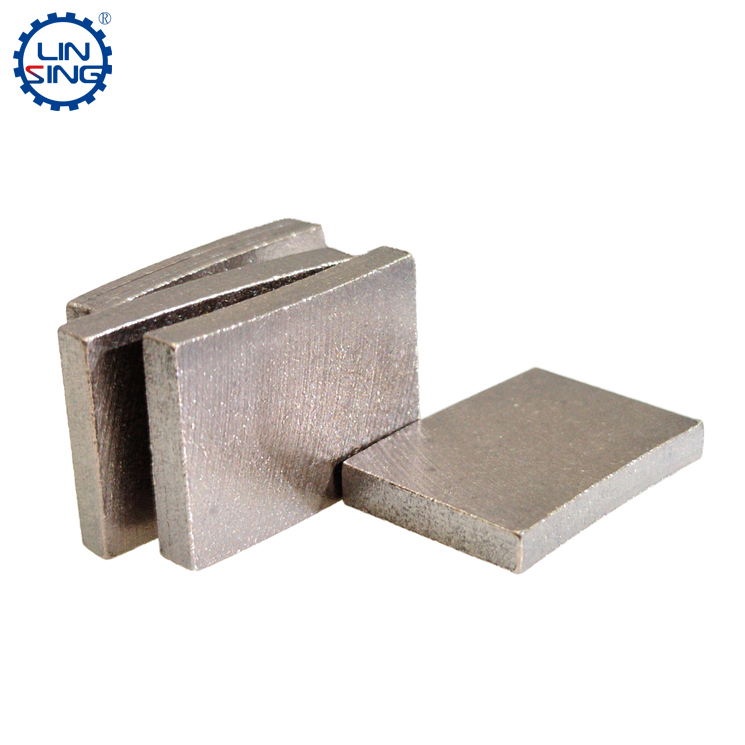

The earliest appearance of the layers segment is the sandwich segment. This segment is divided into three layers, with a non-working layer in the middle and a segment on both sides. The thickness of the non-working layer is adjusted according to the abrasiveness of the stone and the efficiency of the segment. The layers segment is also gradually appearing, from 5 layers to 7 layers and 9 layers, the number of layers gradually increases. Under the condition of the same segment size, the increase of the non-working layer can make the diamond of the working layer be better exposed, thereby having more Good cutting efficiency.

The non-working layer of the layers segment is not randomly configured. Generally speaking, the non-working layer is finely configured according to the current segment bond formula. During the processing, the non-working layer needs to be cold pressed first. During the sintering process, The working layer and the non-working layer are arranged in the graphite grinding tool in turn. The final produced segment will have very obvious layers. So what is the effect of the non-working layer of these layers segment? There are five main functions:

First: Make the segment sharper. Because the non-working layer of the interlayer segment is less abrasive than the diamond-agglomerated working layer, during the cutting process, the interlayer of the interlayer segment will form a concave groove, and the cutting surface will be convex. During the cutting process, the convex cutting surface is Under the same cutting speed and cutting speed, the pressure is constant and the pressure is increased, and the working layer of the segment can be cut more easily.

Second: the segment can be cooled more quickly. Diamond segment is generally welded on the saw blade by high-frequency welding process. During the welding process, solder lug is generally used to connect the matrix and segment. Most of this solder lug uses silver solder lug or copper solder lug. In terms of high temperature resistance, it is not Outstanding, so in the process of cutting stone, we usually spray cold water and coolant on the cutting part of the segment. Because the segments of the layers segment are recessed in the non-working layer, these grooves form natural water flow grooves during the cooling water supply process, so the segments can be cooled more quickly, reducing the risk of segment shedding and tooth loss.

Third: the layers segment is easier to remove chips. During the stone cutting process, a large amount of stone dust and some stone chips or pebbles will be produced. If these stone chips do not come out of the stone cutting gap well, it will affect the cutting of the saw blade, such as causing partial wear of the saw blade. Secondary cutting causes waste, etc. The non-working layer of the layers segment can well remove the stone chips, thus ensuring a better and more stable cutting of the saw blade.

Fourth: The welding of layers segment is more stable. Compared with the segment without layers, the welding surface is relatively single, and the welding surface of the layers segment is distributed in each working layer and non-working layer, so the welding is more stable and the risk of the segment is reduced.

Fifth, it is easier to sharpen the edge. The layer segment is very easy to sharpen because it has a non-working layer. When cutting the stone, this part naturally forms grooves, which makes the saw blade easy to sharpen.

The layers segment and non-layers segment produced by Jiangxi Linxing Diamond Tools Co., Ltd. have stable quality, diverse styles, fast cutting, and long cutting life. Customers are welcome to visit the factory and discuss cooperation.