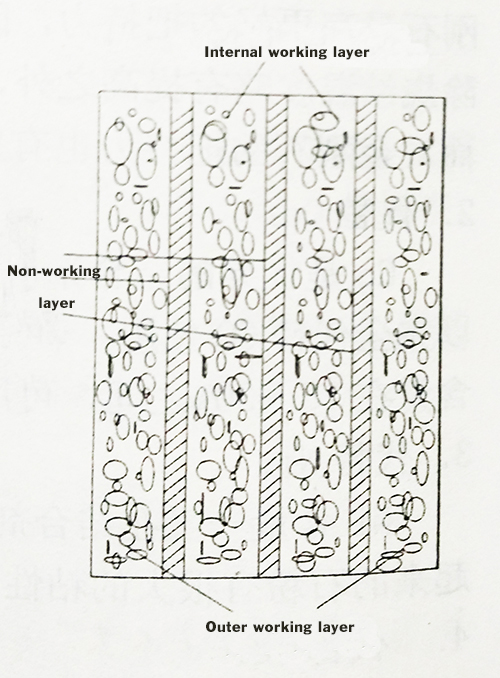

There are many kinds of layered segment, first from the number of layers to consider, divided into 3 layers, 5 layers, 7 layers, 9 layers, 11 layers and so on. And secondly, taking into account the width of the design work layer, from 1mm to 10mm, non-working width will also vary according to the cutting material. In general, the number of layered and the width of the layered directly affect the performance of the cutting of the segment, almost all of the layered segments follow the following characteristics:

The layers is narrower and less segment’s advantage is higher life. We also called this segment sandwich segment. Compared with the traditional non-layered segment, this three-layer layered segment includes two layers of work layer and the middle layer of iron non-working layer. In terms of efficiency has been slightly improved, but life has not been much reduced. Therefore, this segment is suitable for cutting not abrasive stone. But to cut more hard stone, it’s not working well as the soft stone like marble.

The layers wider and less segment’s advantage is lower life but the price is relatively cheap. The most obvious point of this segment is the left and right side for the narrow working layer, and the middle is a very wide non-working layer, this segment is suitable for cutting soft and brittle stone, especially volcanic rock, soft marble and granite, can use this segment.

The layer is narrower and more segment, generally speaking, the layer narrow indicates the sharpness performance in general, but the mezzanine more, and reflects the sharpness of the better, so this narrow multi-layer segment in such a contradictory design, there will be a life is not reduced, sharpness is not increased, and no layered segment, the price of this segment is cheaper, so the versatility is also stronger. Suitable for cutting soft, medium-hard and other abrasive marble and granite.

The layer wider and more segments are currently the most widely used, as for the increasingly expensive diamond, the segment can significantly reduce the production costs of the segment, and the multi-layered segment can also make the sharpness of the segment sharper. The disadvantage is also very obvious, that is, the life will be less, the production process increases leads to high labor costs. This segment is suitable for cutting hard, ultra-hard and other hard stone, especially for the higher abrasive stone, so that the design of the layered segment in the cutting efficiency, reflected very obvious.

Diamond segment development to today, man-made diamond technology has reached the bottleneck. How to make the segment more efficient, longer life, mainly through structural changes. In fact, the impact of structural changes on the segment products is very large. Layered width and narrow difference of one millimeter, may cause the life and efficiency deviation of the segment more than 30 percent, so the development of the segment structure has been the focus of Lin Xing diamond tools, at present, Lin Xing diamond segment in the design of the stratum segment, research and development in the forefront of the industry, the production of layered segment style diverse, advanced technology, for the vast number of customers to provide cheap segment products, by the customer trust.