In just a few decades, people have gone from contacting diamond saw blades to today. It is only a short 100-year history, and the use of saw blades by the Chinese has only been a short 30 years, in such a short time. Inside, the technology of diamond segment is changing with each passing day. Many people don't know what diamond segment has experienced over the years, and many people stay on the way they used segments more than ten years ago. And their wrong way of using segments also leaves many people without any understanding of the current development of segments, which increases production costs for no reason. So today, how do we use diamond segment well? This article elaborates from three aspects:

1: Use a more suitable segment

When people choose a segment, they often buy what segment they have, and they don’t customize the segment according to their own conditions. This is a very big misunderstanding. Common segments are relatively balanced in terms of lifespan and efficiency, which will lead to the process of processing. However, factories that focus on efficiency cannot get higher processing efficiency, and factories that value segment life do not get longer-life segments, which increases production costs. Therefore, personalized customization is suitable for the segments of various manufacturers, which is an important problem that the stone factory needs to face.

2: Use the same specifications and same brand segments

Although the segment shapes of each manufacturer are similar, many people like to use them together. This will result in a situation where the degree of segment wear is different, resulting in eccentric wear of the segment. If the selected segment is a segment with high life and low efficiency, some segments use High-efficiency and short-life segments are prone to constant adjustment of parameters during machining. Otherwise, the saw blade and machinery will be damaged. Even some stone factories choose segments of different sizes for cutting. Such saw blades will greatly damage the force of the substrate during the cutting process of the saw blade. In severe cases, it may even cause the substrate to deform, resulting in small losses. Therefore, in the process of using segments, try to ensure that the quality of the segments is consistent, and even best if the product batch numbers are consistent.

3: Use segment with better cost performance

It’s not that expensive segments are all good segments, and it’s not that low-priced segments are bad. Segments pay attention to cost performance. At present, most stone factories calculate how many meters or square meters can be cut with a set of saw blades. Calculate the life span of a group of segments, but efficiency is often overlooked. A more scientific calculation method is how much electricity, water, labor, and miscellaneous expenses are consumed by cutting a complete set of segments, and continue to spread these into the processing cost of each group of segments, so that the calculation will be more scientific and can better reflect the cost performance of the segment.

4: Use more reasonable processing machinery

At present, if there is a stable cutting speed and a stable feed speed during segment cutting, the life of the segment will be longer, but if the cutting speed is continuously variable, it will only shorten the processing life of the segment. Therefore, although choosing a more stable automatic cutting machine has a large short-term investment, in the long run, it is a way to increase efficiency and reduce processing costs.

5: Use of coolant

At present, only some manufacturers of stone processing will use coolant. Although it seems to increase the cost, in practical applications, the coolant quickly cools the segment, allowing the segment to work at a lower temperature, which is in fact disguised. Increase the stability of the segment, and also increase the service life of the segment. The main reason is that the segment heating under long-term high-speed work will make the matrix and diamond powder unstable, and even diamond carbonization will occur, which will lead to the deterioration of segment quality.

6: Train high-quality operators

The same set of sub-segments, when used by skilled operators, can improve the performance of the segment by more than 30%. Through the segment cutting business during the cutting process and the smoothness of the blade cutting, you can find the problems in the processing The diamond segment has been in normal operation for a long time, and can also ensure production safety and production efficiency.

7: Choosing higher-power high-frequency welding equipment and choosing better solder to weld the segment is also a very important part of the process of segment use.

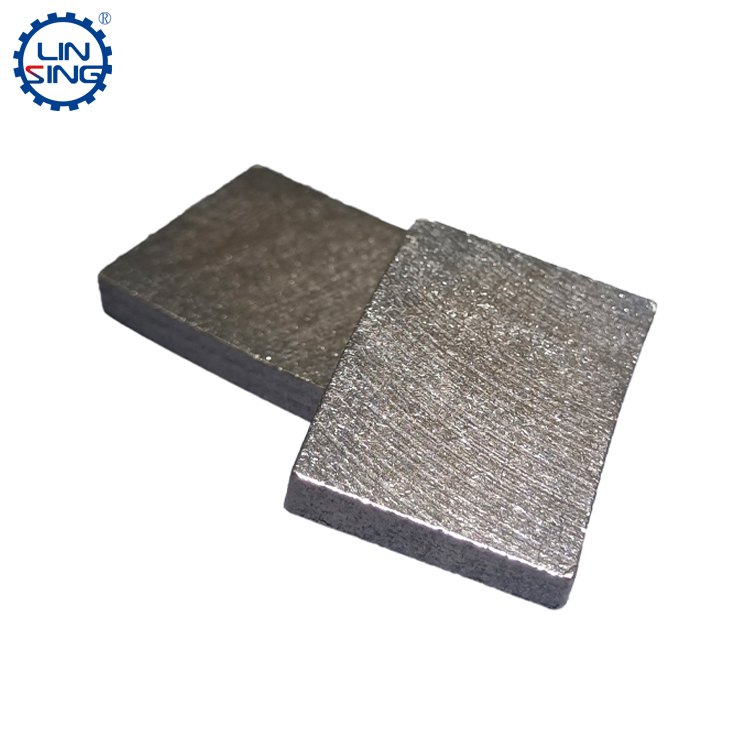

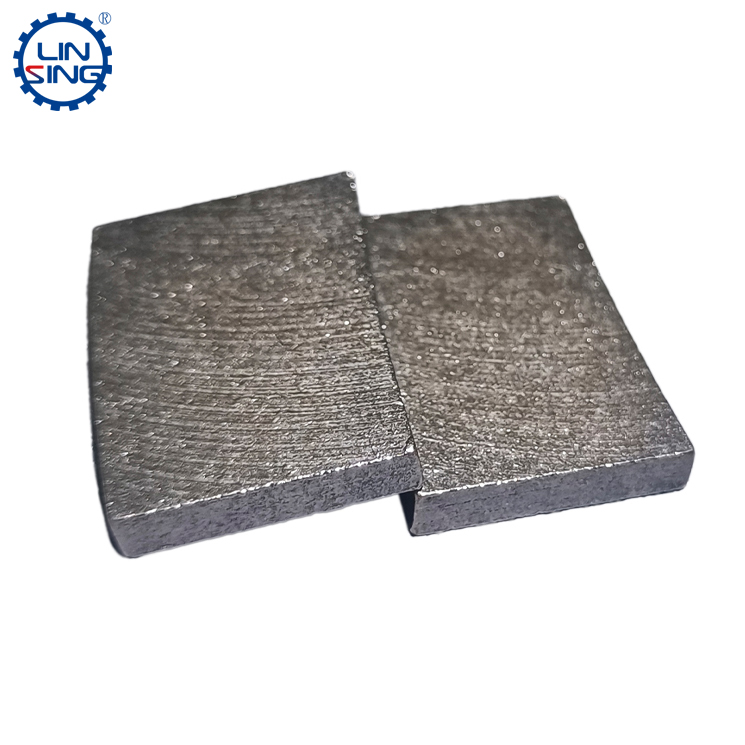

In the process of using diamond segment, you need to pay attention to the situation of the segment at all times, and you also need to choose a good segment, Linxing diamond segment. The product quality is more stable, and the service life is also at the forefront of the industry.