The diamond segment production process is a very meticulous workflow. Basically, every step needs to be tested to better stabilize the segment quality and prevent defective products from entering the next process. Although it will cause a lot of inconvenience in the production process, in terms of results, the stability of the product is guaranteed to the utmost extent. Therefore, Jiangxi Linxing Diamond Tools Co., Ltd. uses twelve inspection processes to ensure the diamond segment produced by Linxing's quality.

1: Particle size detection. When diamond powder is purchased and put into storage, the company will use mesh screens to detect the size of diamonds, and sample multiple batches of particle size to ensure the uniformity and applicability of diamond particle size.

2: Diamond structure inspection. After testing the particle size, Linxing will use a high-power microscope to analyze the diamond structure to ensure the stability of the diamond structure. Currently, the company’s diamond powders are made of high-quality diamond powders with high deformation, high wear resistance and resistance. This will pave the way for the production of high-quality segments in the later stage.

3: Detection of metal bond materials. For the carcass bond, the company selects high-quality metal powder, especially in the detection of cobalt metal, the company uses advanced testers to analyze the composition and quality of rare elements.

4: The diamond particles are treated with vacuum titanium plating, and the titanium plating layer is analyzed. At present, the titanium plating process is applied to the segment, although it increases the process cost, but in the sintering process, the oxidation of the diamond powder is minimized, and the service life and cutting efficiency of the segment are also guaranteed to the greatest extent.

5: Check whether the mixing of the segment powder and diamond powder after the numerical control mixing is complete. This test is the most important test in the segment production process. If the powder is not mixed uniformly, the segment quality will be unstable and will appear Problems such as segment loss of teeth and inability to cut stone.

6: Cold pressed agglomerate weighing. When the powder enters the cold press, solid agglomerated cold pressed agglomerates will appear. According to the total mass of powder and the total number of segments expected to be produced, calculate the weight of a single cold pressed agglomerate. If the weight is too high or low, it needs to be cold pressed again.

7: In addition to weighing, the cold-pressed diamond segment requires Rockwell hardness tester to test the agglomeration hardness to ensure that the agglomeration hardness error does not exceed five thousandths, otherwise it needs to be re-made.

8: Segment weighing detection. After the cold-pressed sheet is hot-pressed and sintered, the entire sintered agglomerate needs to be weighed. The weight measurement is to ensure that the segment quality is more stable.

9: Segment size detection. The size needs to be checked by a vernier caliper. If the segment size is different, later welding problems will occur, and stone scratches will also occur.

10: Detection of the resistivity of the hot-pressed segment. The current can be adjusted more accurately by detecting the resistivity, so as to ensure the sintering temperature and improve the stability of the segment quality.

11: Professional equipment detects the volume of the segment to obtain the density of the segment agglomeration, and judge the stability of the segment product from the density.

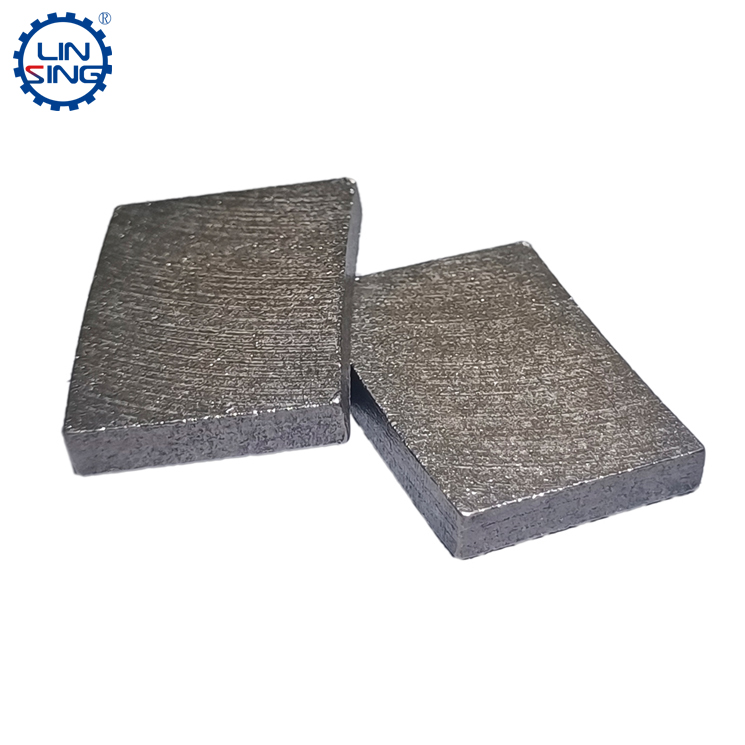

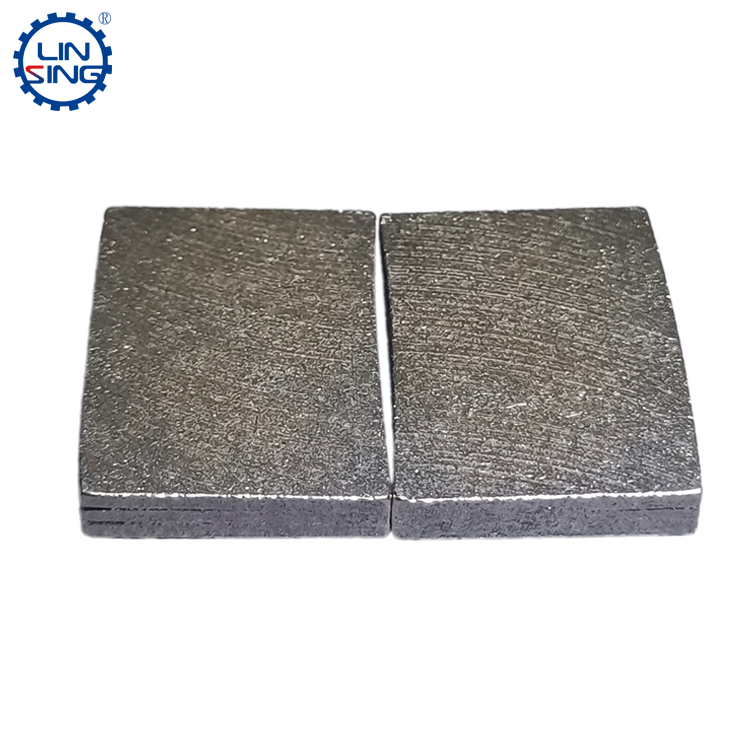

12: Appearance treatment and inspection. After the segment is finally formed, it is necessary to perform appearance treatment on the segment, and then perform processes such as polishing and sandblasting to make the diamond segment appearance and product quality more stable.

Diamond segment manufacturing inspection process

Publish date:2022-07-06 19:14:03 Article From:Linsing Diamond Tools Clicks: