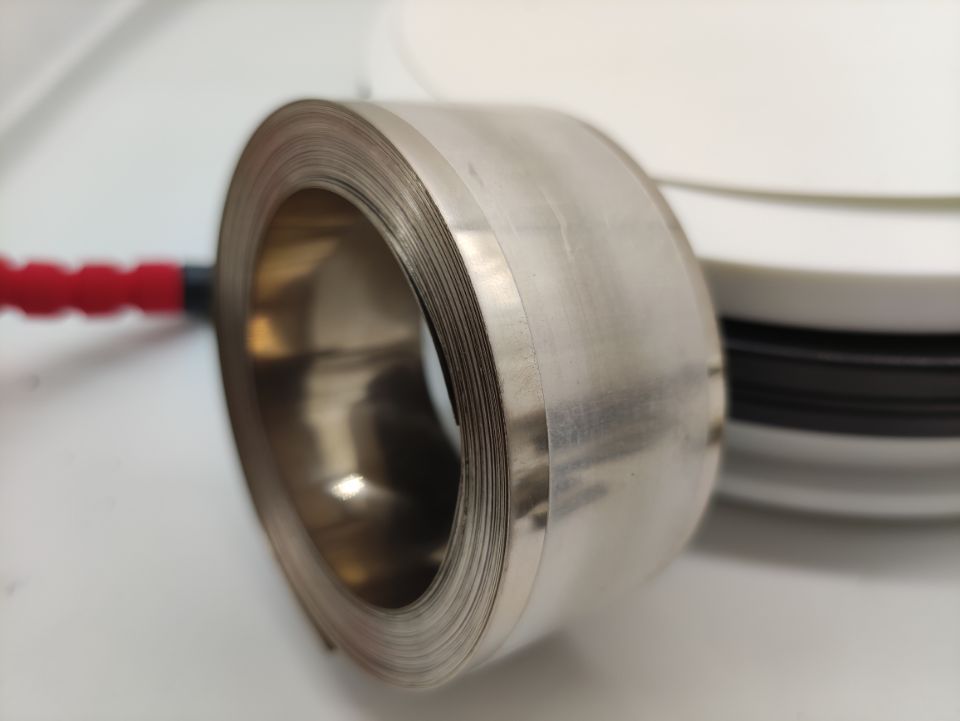

Stone saw blade is a special saw blade, in the cutting process, high-speed operation of the blade produces a lot of heat. The general temperature is too high, welding point will soften the situation, so the segment off is also very normal. We need to choose some of the temperature impact of less stable metal as solder, the most common solder is silver solder and copper solder.

Silver solder is a very common solder, this material solder has high welding strength, good stability, easy removal and low temperature impact. So, it not easy to oxidize and other advantages, as shown in the stone saw blade normal welding conditions, bending up to 600N/mm2 (MPa), heat resistance and impact resistance are higher than other metal solder, the disadvantage is that the price is higher and welding time will be longer.

Copper welding solder are often used for low-cost saw blade products. these solders have affordable, easy to weld and some other advantages as well. However, the disadvantages are also obvious: antioxidant is not strong, easy to rust, and the firmness is not high, not suitable for cutting hard stone; in the later removal of waste segment, there will be difficult to peel off, thus affecting multiple welding. In general, the bending degree of the copper solder plate can only reach 350-450N/mm2 (MPa), so there will be appear the situation which segment prone to fall off.

In addition to solder plate, we also need fluxes, fluxes have solder paste and borax two kinds, solder paste is liquid-like metal material, mainly have silver solder paste and silver copper solder paste. In the welding process, the solder paste applied to the solder plate. And then placed in the welding machine, and the role of the solder paste is fusion, when the temperature is high enough, the solder melts, the solder paste can fully fuse the metal elements of the welding, the segment and substring tightly connected together. With the addition of welding paste. It will obviously improve the welding strength of the diamond segment, and the stability can be greatly improved.

Borax, on the other hand, is a special antioxidant. Borax in the welding process, melted into a liquid, in the surface of the welding material to form a thin antioxidant film. This layer of antioxidant film can maintain the welding area for a long time in the flushing of cooling water without oxidation, thus ensuring stable cutting of the segment.

Diamond segment welding is a very important process, so welding materials should choose a better product, otherwise maybe will appear the situation of the segment falling, or welding failure to lead to the occurrence of production accidents will not be worth the loss.