The use of wire saws in mining operations is primarily due to several reasons:

1: Efficient cutting: Wire saws enable quick and efficient cutting of large rocks and minerals, significantly improving mining efficiency compared to traditional methods.

2: Flexibility: Wire saws are flexible and adaptable to different shapes and sizes of rocks and minerals. They can be operated along desired contours, providing high flexibility in cutting angles.

3: Safety: Wire saw cutting process is relatively safe, especially with the implementation of remote control cutting capabilities. Operators can maintain a safe distance from the cutting area, reducing the risk of accidents, which is particularly important in challenging mining environments.

4: Cost-effectiveness: Wire saws have lower investment and operational costs compared to other large cutting equipment. They require less complex machinery and consume less energy, reducing mining costs and improving economic efficiency.

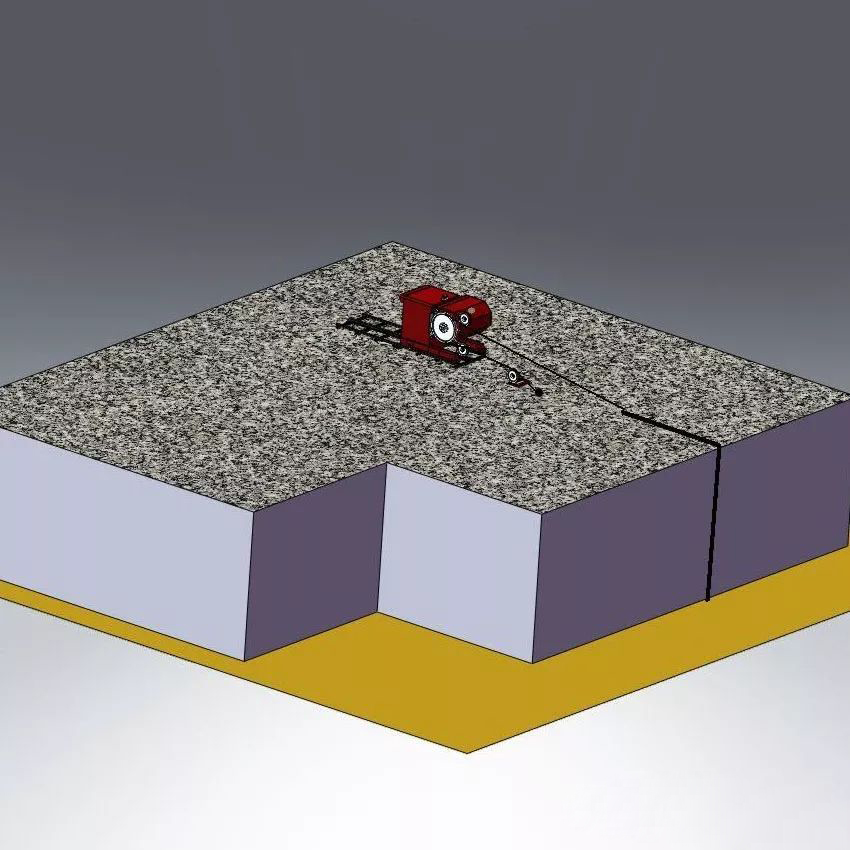

5: Versatility: Wire saws can be used for cutting various types of rocks and minerals, including hard rocks, coal, and iron ore. They are suitable for different hardness levels and thicknesses, offering a wide range of applications, including cutting marble, granite, reinforced concrete, and steel plates. Dry cutting wire saws are also available for mining in waterless environments.

6: High precision cutting: Wire saws provide stable cutting processes and high cutting precision, allowing for precise cutting contours and dimensions, minimizing material waste. CNC wire saw machines can achieve cutting errors below 0.1mm, especially for cutting curved stones.

7: Strong controllability: Wire saw cutting speed, cutting depth, and cutting trajectory can be precisely controlled, adjusted according to specific mining requirements. Operators can optimize the cutting process for the best results, even remotely.

8: Environmental friendliness: Wire saws utilize mechanical cutting principles, generating less dust and waste compared to traditional methods. They are energy-efficient and reduce environmental pollution, aligning with the principles of green and sustainable development. Wire saws also produce lower noise levels, minimizing noise pollution.

As an advanced cutting tool, wire saws offer numerous advantages in mining operations. They enhance work efficiency, ensure cutting quality, improve safety, and reduce overall costs. These benefits have made wire saws an important tool in the mining industry, leading to their increasing adoption for mining operations.