There are two factors will determine the quality of the diamond segment: the first is the sharpness of the segment, the other is the lifespan of the segment, the former determines the basis of the work of the segment, and the latter determines the core competitiveness of the segment.

Because if the segment does not sharpness enough, cutting work will hardly be completed, this situation is called segment can’t cut, and such a segment is the most unacceptable in the market. With the development of the diamond tool industry, at present, Lin Xing diamond tools almost do not happen this problem.

Under the premise of sharpness guarantee, the segment wear consumption too fast has become the second problem that Lin Xing diamond tools need to overcome: first of all, we need to understand the reasons for this problem. There are five main points:

1: The bond is too soft to cause the segment is not wear-resistant, this reason is well understood, the segment is by the fetal binder and diamond powder sintering tips, when the bond is not hard enough, natural wear consumption is fast, then the bond consumption is fast, diamond powder holding force is not enough, a large number of shedding, resulting in a reduction in cutting life. Such a segment, in the cutting process, diamond did not play its due role, resulting in waste.

2: Diamond powder concentration is less: diamond powder content is too less, then the cutting process, diamond powder will be consumed very quickly, although the sharpness is higher, but the life due to the lack of diamond powder led to the decline in cutting life. This segment maximizes the use of diamond powder, but the disadvantage is that the bond is consumed too fast.

3: The stone is eexcessive abrasiveness or hardness: Some stones have extremely high abrasiveness and hardness. Excessive diamond powder consumption during the cutting process will also cause the diamond segment to wear too quickly.

4: Wrong mechanical settings. Some operators in the cutting of stone, Regardless of the capacity of the saw blade, the use of excessive speed, moving speed and cutting depth. the segment in a long-term overload operation, physical and chemical performance reduced, resulting in the segment become extremely unstable, resulting in excessive consumption. There is also the mechanical operation process to provide water is not enough, resulting in the segment in a high temperature state for a long time, the inside of the segment diamond carbonization, resulting in the sharpness of the cutting of the segment, followed by the segment wear speed up the situation.

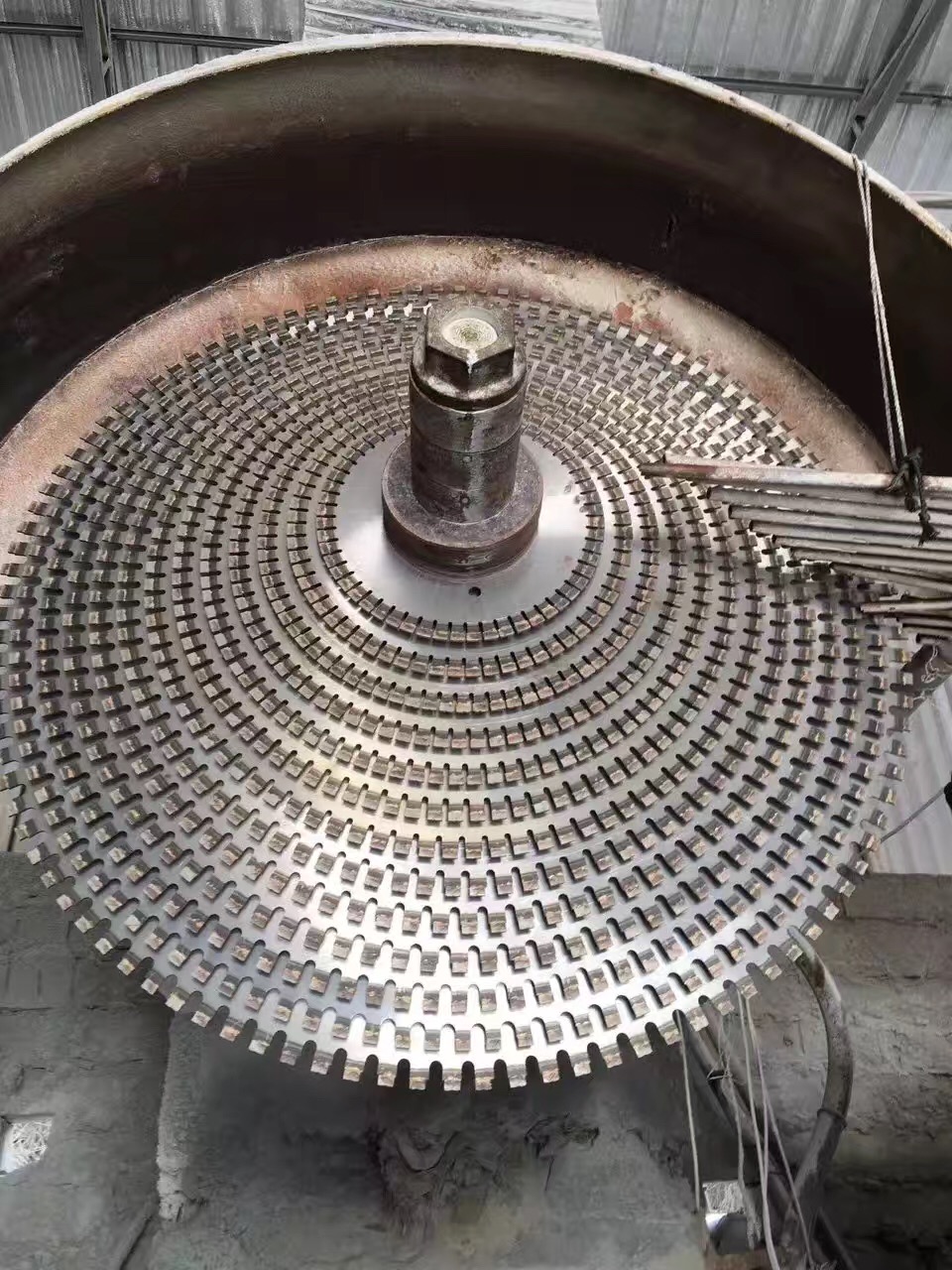

5: The segment design is unreasonable, if the segment non-working layer is too wide or the shape of the segment care much about sharpness, then the segment is prone to wear and wear fast situation.

The above reasons are common reasons for the excessive consumption of the diamond segment. And there are also have uncommon reasons, such as uneven mixing process during the segment production process, insufficient hot pressing temperature of the segment, low hot pressing pressure of the cutter head, etc., all these reasons will cause problems happening.

When encountering the situation that the diamond segment is consumed too fast, it is best to eliminate the mechanical and human problems first, and then contact the diamond segment manufacturer as soon as possible to give the problem encountered and the life expectancy, so that the manufacturer can deploy a better segment to reduces the manufacturing cost of the factory.