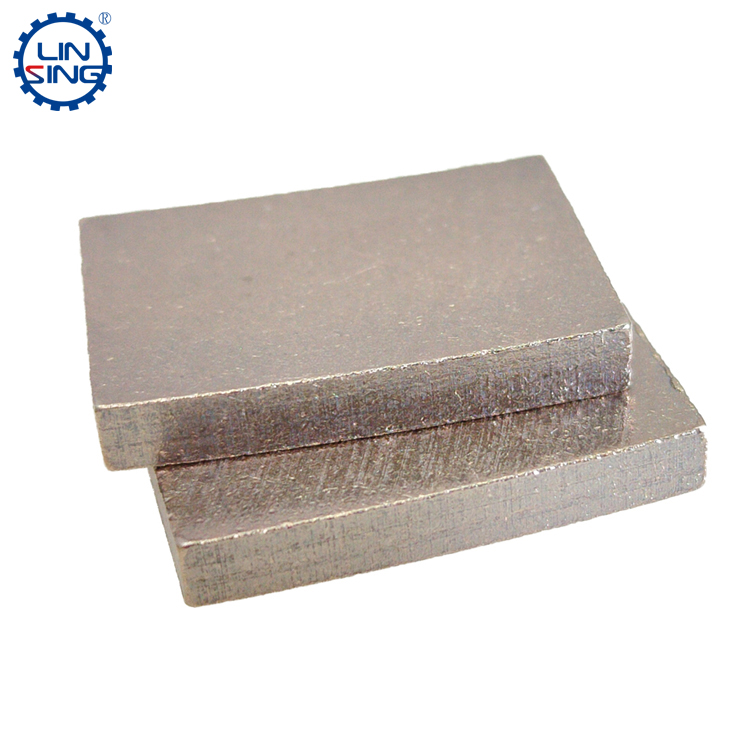

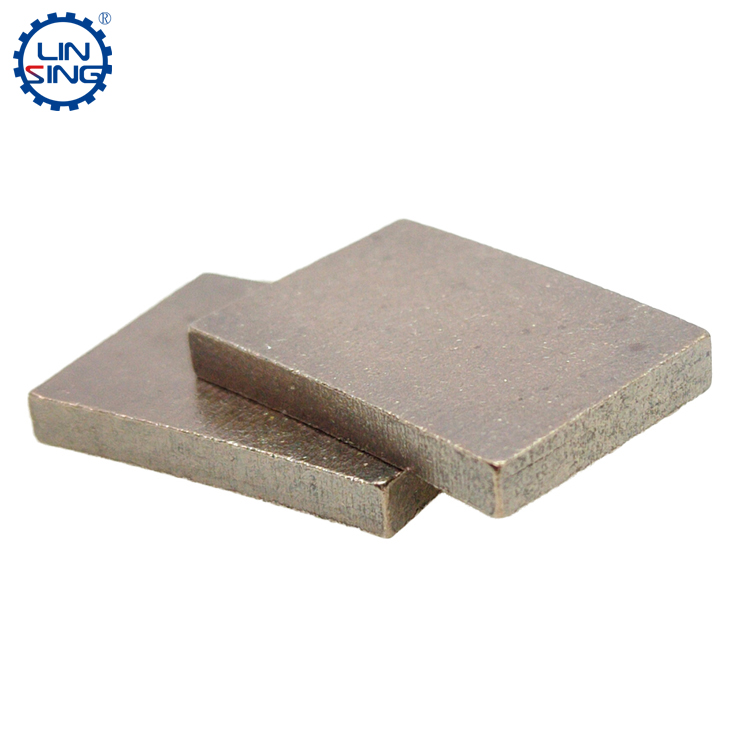

Marble segment is a special segment product used for cutting marble blocks, plates, special-shaped and other materials, which are mainly welded on cutting tools as the main cutting teeth. Common marble segments have the following characteristics:

Marble segments are highly abrasive. In nature, there is a large stock of marble. In terms of hardness, it belongs to medium-hard stone. In terms of abrasiveness, it also belongs to medium-hard material. Because the material of this material is hard, it is necessary to ensure the sharpness of the segment, and because the marble is abrasive For high-performance stone, segment loss is also greater during the cutting process, so it is consumed very quickly. Therefore, the most important thing for a marble segment is to ensure its sharpness while also ensuring its service life. Increasing the abrasiveness of the segment is also very important. How to increase the abrasiveness of the marble segment? There are several ways, first: increase the hardness and strength of the metal bond to slow down the consumption of segments. Second: Use high-concentration diamond powder to increase the cutting performance and abrasiveness of the segment. Third, use large-size diamond powder with high-strength metal bond to form trailing traces formed by natural cutting on the segment. Fourth, the appropriate use of diamond with high hardness can slow down the consumption of the segment, thereby increasing the life of the segment.

Marble segments are generally designed without compartments. In the marble segment design, there is generally no partition. Even if there is a partition, only a thinner partition is designed. This can appropriately improve the sharpness while ensuring the life of the segment. This type of segment is called a sandwich segment.

The marble segment has grooves on the side. For better cooling of some marble segments, two narrow grooves are designed on the side. When the segment cuts the stone, water can pass through such grooves to reduce the segment temperature, thereby ensuring the stability of the segment. Good to increase the life span of the segment.

The marble segment is yellowish in color. There are four main types of bonding agents for diamond segment: copper-based, iron-based, cobalt-based, nickel-based, etc. At present, a new type of silicon carbide bonding agent material has not been widely used. However, marble segments basically use copper-based and cobalt-based materials. The advantage of copper-based is that the price is cheap, the segment has good rigidity, long service life, good wear resistance, and high hardness. The disadvantage is that it is easy to be unstable when heated. However, the price of cobalt base is much higher than that of copper base, so it is mainly used for gang saw segment. Copper-based and cobalt genes are due to their own materials, especially copper-based marble segments, which are yellowish in color.

The shape of the marble segment is single, and most of the marble segment shapes are simple. There is no M-shape or K-shape on the side, and there is no single-layer and three-layer anti-sticking design, and the sides are uniform.

The height of the marble segment is relatively short. During the cutting process of the marble segment, if the segment quality is excellent, the service life can be guaranteed. Therefore, in the design, the marble segment height will be designed at 10mm. This design can minimize the swing of the saw blade due to high-speed rotation. Thereby increasing stability.

LINXING marble segment takes into account sharpness, life and abrasiveness, and has good feedback in various markets at home and abroad. Because of its focus, it is professional.

Marble segment features

Publish date:2022-07-07 08:44:22 Article From:Linsing Diamond Tools Clicks: