It is known that diamond is the hardest material in nature, we can easily get this knowledge from books. Diamonds are found in small amounts in nature. And because of its whiteness and transparency, coupled with its hardness, it is considered a symbol of purity and steadfast love, so it is expensive. Under such circumstances, it is difficult for natural diamond to become an industrial processing material.

Due to the development of chemistry in the 20th century, people discovered the secrets between matter. In particular, graphite and diamond can be converted into each other. It has been found that graphite can be turned into diamond under high temperature and high pressure through the six-sided top machine. This discovery soon led to the industrial mass production of diamond, and the diamond saw blades were also produced in large quantities. The diamond saw blade can cut hard objects. Since the appearance of artificial diamond has greatly reduced the production cost, what role does it have?

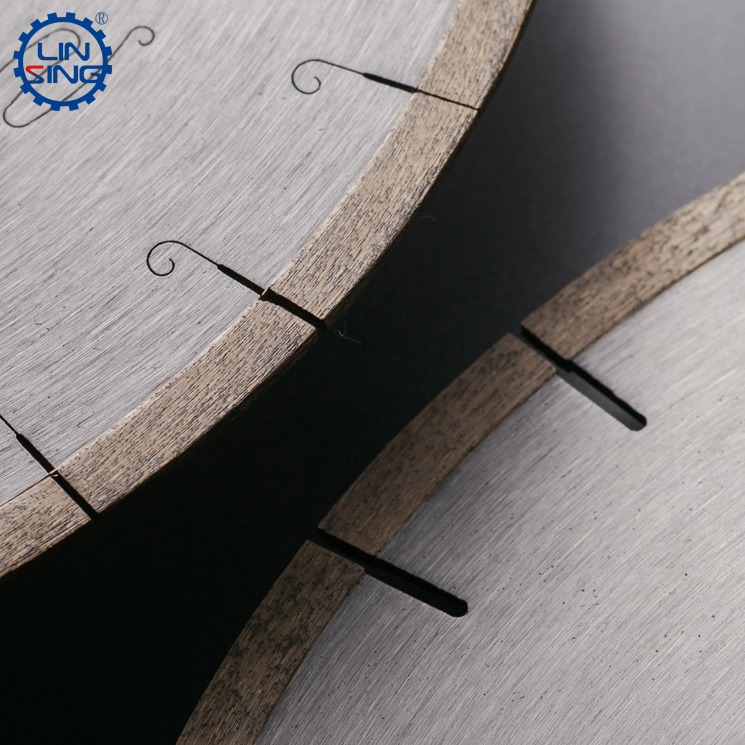

Generally speaking, the working environment of diamond saw blades is relatively harsh, and the primary use of the product is to cut stone. They are widely used in marble, granite, sandstone, limestone, volcanic rock, basalt, slate, quartz stone, travertine, agate, andesite, jade and other natural stone processing. But with the continuous research and development of artificial stone. For example, synthetic granite, phoenix microcrystalline stone, slate, terrazzo and other stones are continuously cut by diamond saw blades. As a result, diamond saw blades are used more or less in almost all stone cutting processes. For example, quarry saw blades used in mining, multi-blade for block cutting or large-sized single saw blades. Medium diameter saw blades for infrared cutting machines for stone mid-cut and stone slabs, or small cutting blades for on-site stone cutting.

Gradually, it was discovered that diamond saw blades can also be used to cut ceramic wall and floor tiles. Although most of the cutting of tiles will still be cut with a ceramic cutting machine. However, in some corners, door covers, window covers, special-shaped tile modeling cutting, stair boards and other on-site decoration, turbo discs still have many uses. Ceramics are also suitable, which are products with softer hardness and higher brittleness. During the cutting process, we must pay attention to the beating range of the diamond segment on the saw blade, and also consider the saw teeth shape of the saw blade, so as to increase the continuity and improve the cutting quality.

Finished concrete and reinforced concrete cutting, it is a very useful piece of diamond saw blade at present. Especially at present, as steel-concrete buildings have gradually become the mainstream of the world. In the process of demolition of old buildings, steel-concrete and concrete cutting, and even wall cutting. Diamond saw blades are the primary and widely used processing equipment in the building materials industry.

The reason why the diamond saw blade has such a cutting ability is mainly because the diamond saw blade cutting has the advantages of easy operation, high efficiency and good processing quality. However, the disadvantages are also very large. For example, the noise of the saw blade is particularly loud during the cutting process, which is not environmentally friendly. And if the saw blade is used for a long time, there will be insufficient rigidity. During the cutting process, problems such as vibration and deviation are prone to occur, which not only cause problems in cutting, but even damage the machine.

In order to make the circular saw blade cut better, increasing the thickness of the saw blade base is a good solution to this problem. However, the unfavorable factors have also increased, such as greater cutting consumption, greater current and water flow, higher segment cost, lower feeding depth, and low cutting efficiency.

At present, people can make diamond into PCD, PDC, PBCN and other materials through higher-tech processes. It is now widely used in cutting many glass, wood and other industrial materials, even steel and alloys can be used.

The usage of diamond saw blade

Publish date:2022-09-19 20:35:22 Article From:Linxing Diamond Tools Clicks: