The performance of diamond segments mainly includes two aspects, sharpness and wear resistance. Sharpness represents the speed of cutting and the efficiency of the saw blade in actual use, while the wear resistance of the blade determines the service life of the blade. Generally speaking, the wear resistance of the segment is not as high as possible, nor as low as possible, but there is an applicability that matches diamond. Normally, in the sawing process, the sharpness is the cutting efficiency, and the wear resistance is the service life of the saw blade. Efficiency and service life are two important indicators to measure the comprehensive performance of diamond segments. In the actual use process, people found a problem. When the efficiency of the same saw blade is improved, the lifespan will inevitably be reduced. So if you want to increase the cutting life, then reducing the efficiency seems to be the only option. In the recent years of the development of diamond segments, most of the segment design tests are based on these two factors, in order to make them show ideal work efficiency and service life during use. The cutting efficiency and service life of diamond saw blades are closely related to the formula of the segment, and the formula of the segment mainly depends on the parameters of the selected diamond and the parameters of the matrix. The above is the relationship between the sharpness and wear resistance of the diamond bit under normal circumstances, but there are three factors that will affect the sharpness and wear resistance of the diamond segment.

In the recent years of the development of diamond segments, most of the segment design tests are based on these two factors, in order to make them show ideal work efficiency and service life during use. The cutting efficiency and service life of diamond saw blades are closely related to the formula of the segment, and the formula of the segment mainly depends on the parameters of the selected diamond and the parameters of the matrix. The above is the relationship between the sharpness and wear resistance of the diamond bit under normal circumstances, but there are three factors that will affect the sharpness and wear resistance of the diamond segment.

First, the parameters of diamond depend on the concentration of diamond segments.

Under normal circumstances, if the average distribution density of diamonds on the surface of the segment carcass, that is, the working surface, is greater, the better the wear resistance of the segment. The diamond in the segment continuously participates in cutting, and the service life of the segment will naturally be longer; on the contrary, if the diamond cutting area is smaller, the wear resistance will be worse due to the weakening of the stone cutting ability. The lifespan is naturally shorter. In terms of efficiency, if the concentration of the diamond segment is higher, within a certain range, the cutting efficiency of the diamond segment will also be improved. When the diamond density per unit volume exceeds the critical concentration point, the sharpness of the segment will decrease with the increase of the diamond particle size per unit volume. At the same time, after the life of the segment reaches a certain value, there will be no change in the life.

Second, Apart from the concentration of diamond, the bezel strength is also an important factor affecting the sharpness and wear resistance of the diamond segment.

The bezel strength refers to the bonding strength of the diamond and the matrix structure, also known as the holding force. The higher the holding force of the matrix on the diamond, the stronger the diamond's full cutting ability, which is the principle in the process of diamond cutting stone. The sharpness of the diamond segment is related to the exposure speed of the diamond particles contained in the working layer on the surface of the carcass. The faster the exposure speed, the higher the contact friction frequency between the diamond particles and the material to be cut during the cutting process, and the sharper the segment. The exposure speed of the particles is determined by the holding force of the segment matrix binder. The stronger the holding force of the matrix, the slower the diamond particles are exposed and fall off. On the contrary, the weaker the holding force of the matrix, the faster the diamond particles are exposed and fall off. It can be seen that the stronger the holding force of the diamond saw blade matrix, the weaker the sharpness of the segment, the weaker the holding force of the matrix, and the stronger the sharpness of the segment. Cutting efficiency and cutting life can be greatly improved, but if the holding force is not enough, the sharpness and life of the segment are often very short.

Third, the factor that affects the sharpness and wear resistance of the segment is the particle size of the segment.

The larger the particle size, the stronger the impact force will be on the diamond in the process of cutting the stone with higher hardness, which will cause the diamond in the segment to break rapidly, especially the large diamond breaking surface. In this case, the sharpness and wear resistance of the segment will naturally be greatly shortened. In other words, the faster the exposure speed of diamond particles, the more serious the friction and impact wear, so the speed of particle shedding also becomes faster, and the faster the longitudinal density of diamond in the working layer of the segment matrix decreases, the faster the diamond particles fall off. The number of diamond layers in the working layer of the carcass is reduced, and the service life of the segment is shortened. The above article expresses the situation that both the diamond segment and the sharpness are affected, but in general, the relationship between the sharpness of the diamond segment and the wear resistance is mutually restrictive, and one trades off the other. If the diamond concentration of the segment is reduced, the segment will start to show improved sharpness, but the life will be greatly reduced. Improving the holding force of the diamond segment can also improve the life of the diamond segment, but if the diamond with large particle size and high strength is combined with the matrix bond with strong holding force, there will be a long life, but low sharpness. Therefore, under normal circumstances, the segment follows this rule: the higher the sharpness, the lower the wear resistance; on the contrary, the higher the wear resistance, the lower the sharpness.

The above article expresses the situation that both the diamond segment and the sharpness are affected, but in general, the relationship between the sharpness of the diamond segment and the wear resistance is mutually restrictive, and one trades off the other. If the diamond concentration of the segment is reduced, the segment will start to show improved sharpness, but the life will be greatly reduced. Improving the holding force of the diamond segment can also improve the life of the diamond segment, but if the diamond with large particle size and high strength is combined with the matrix bond with strong holding force, there will be a long life, but low sharpness. Therefore, under normal circumstances, the segment follows this rule: the higher the sharpness, the lower the wear resistance; on the contrary, the higher the wear resistance, the lower the sharpness.

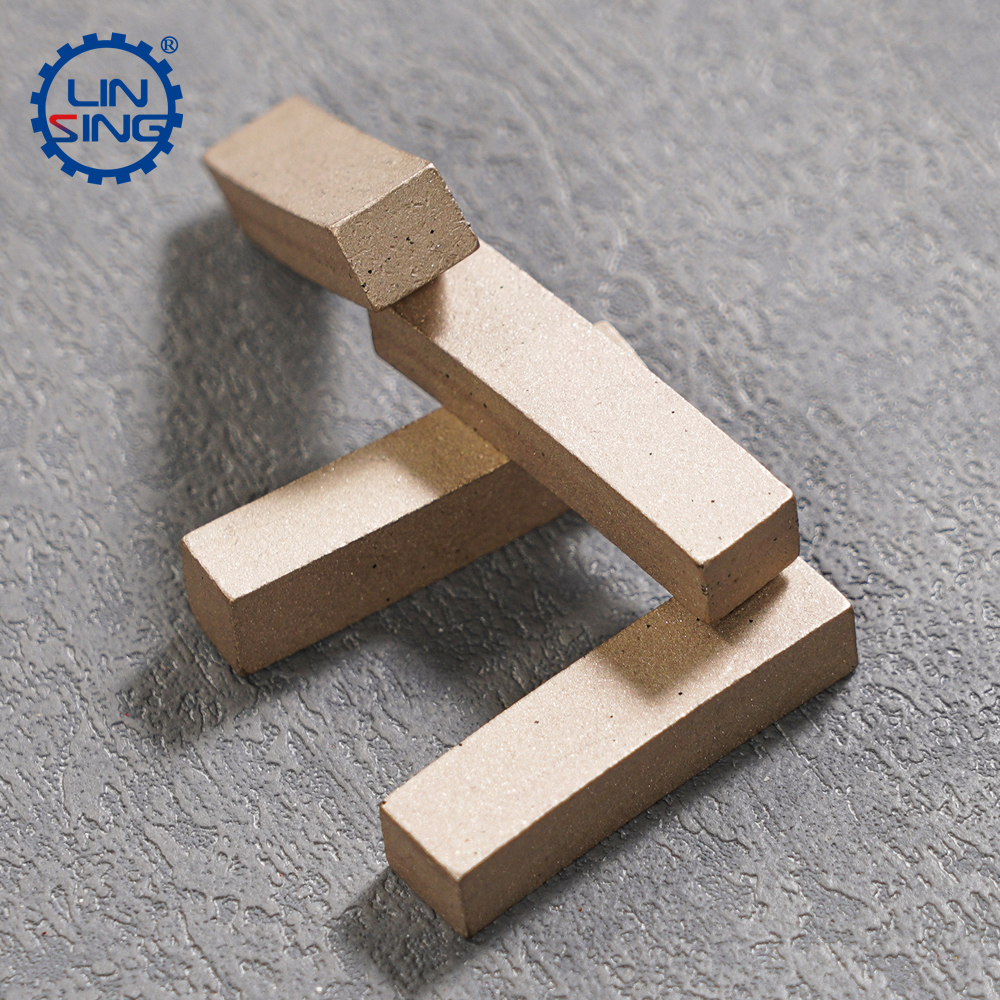

The relationship between the sharpness and wear resistance of diamond segments

Publish date:2022-11-29 14:17:16 Article From:LINSING diamond tools Clicks:

Diamond Segment For Granite Cutting

Diamond Segment For Gang Saw

Diamond Segment For Sandstone Cutting

Diamond Horizontal Blade For Marble

Vacuum Brazed Diamond Saw Blade

Related News

- Several aspects to consider in diamond segment customization

- Diamond segment on diamond requirements

- Liquid phase sintering and solid phase sintering of diamond segment

- 70% diamond segment factory planning adjust price due to diamond powder price is increasing

- HOW TO CHOOSE THE BEST SUITABLE DIAMOND SEGMENTS

Related Knowledge

- Influence Of Diamond Particle Size On Saw Blade Performance

- Relationship Between Tooth Width Of Diamond Saw Blade And Blank Blade Thickness

- Installation Methods Of Diamond Saw Blade

- Introduction Of Common Parameters Of Diamond Saw Blade

- The Relationship Between Wear Resistance And Efficiency Of Diamond Saw Blades