The quality of the diamond saw blade can only be known by trial, and only by choosing the right saw blade can achieve good cutting performance. As a very hard material product, diamond saw blades are mainly used for cutting hard and brittle materials such as concrete, refractory materials, stone materials and ceramics. Some are not sharp to cut, and some have a very short service life. These are common problems encountered by users who do not know much about diamond saw blades. Because of the uncertainty, most customers do not have the professional knowledge of saw blades and professional testing equipment, so this article will teach you how to observe the quality of diamond saw blades with the naked eye. Jiangxi Linxing Diamond Tools Co., Ltd. has been engaged in stone cutting tools for nearly five years. It has sorted out the years of experience of excellent experts in the diamond saw blade industry, and summarized the method of "how customers can roughly identify the quality of diamond saw blades with the simplest naked eye", which we describe below.

Jiangxi Linxing Diamond Tools Co., Ltd. has been engaged in stone cutting tools for nearly five years. It has sorted out the years of experience of excellent experts in the diamond saw blade industry, and summarized the method of "how customers can roughly identify the quality of diamond saw blades with the simplest naked eye", which we describe below.

First: the concentration of emery in the diamond segment part of the diamond saw blade

Diamond is the largest production cost for diamond saw blades. If the concentration is too low, the segment will be consumed quickly and the cutting will be weak during the cutting process. Conversely, if the diamond concentration in the segment is reasonable, the cutting process of the segment will be smoother. But do not overly depending on diamond powder content. Because too high diamond powder content will also bring unfavorable cutting factors, such as the reduction of the sharpness of the segment. Especially in recent years, the segment recycling project has gradually taken shape, and the segment is recycled and washed out of diamonds. The structure of this type of diamond is very unstable, but the price is cheap. Many segment manufacturers purchase this type of diamond powder. In order to avoid the risk of not cutting, they will add a lot of diamond powders to the segment. Most of the time, if the diamond concentration of the segment is too high, but the price is low, most of such saw blades are made of diamond powder that is used twice or multiple times, and the stability and cutting ability will be greatly reduced.

Second: observe whether the exposed emery on the segment is evenly dispersed

Uniformity is a very important parameter. The cutting part of the diamond saw blade is mainly the segment. If the segment part is unreasonably made and the diamond distribution is uneven, various problems will occur. For example, the segment is eccentrically ground, and the segment is high on both sides and very low in the middle, or low in the middle and high on both sides, or the height difference between the front and rear. With such a segment, the cutting capacity is greatly reduced, and only a part of the segment is working. Under super-intensive work, these segments will gradually become flat or even fall off, which will ultimately greatly reduce the cutting life and cutting efficiency.

Third: observe whether the weld is complete and neat

If the weld is discontinuous and the edge of the segment is not vertically aligned with the base water tank, chip evacuation and heat dissipation will be affected, and the segment may fall off. The well-welded segment can observe the level of each segment, place the saw blade straight on the water platform, and keep the sight level with the table. At this time, this observation will clearly find out whether the saw blade welding is flat.

Fourth: lift the saw blade in your hand and observe whether the diamond segment and the base are aligned on the horizontal plane. Or you can use a wrench to gently move both sides of the segment. If the segment is uneven, interlaced and easy to loosen, it is likely to cause the plate to collapse or even the segment to fall off during use.

Fifth: compare the thickness of the segment and the thickness of the blade blank.

Taking a 350mm granite saw blade as an example, under normal circumstances, the blade segment is about 1mm thicker than the blade blank. The 350mm marble saw blade tip will be about 0.2mm-0.5mm thicker than the blade blank. The reason for this design is to avoid damage to the substrate and to increase the service life of the saw blade. However, the thickness of the saw blade is not the only factor to test the quality of the saw blade. It can only be said that at the same price, the thick saw blade has better cutting effect and better stability. The thin saw blade has higher requirements on the sharpness of the segment, and has a finer cutting gap, saving stone.

Sixth: the sharpness and wear resistance of the saw blade is a contradictory relationship between one and the other.

Our advice is that when the blade life has reached the expected target and the sharpness is moderate, do not ask for an increase in the life. Because the external environment (such as the cutting machine, the operation of the workers, the hardness of the stone, etc.) will change at any time, and once the external environment changes, the suitable saw blade will also become unsuitable. Often a factory needs to be equipped with many kinds of saw blades, such as sharp type, life type, and comprehensive or cost-effective saw blades to meet different cutting needs. In the process of saw blade selection, you can choose a more suitable saw blade product according to these labels of the saw blade. Finally, there are many ways to choose a saw blade. Some people will judge according to the appearance defects of the saw blade product, some will judge according to the saw tooth shape of the saw blade, and some will judge according to the material of the saw blade. In general, these methods are only based on some one-sided, not entirely correct.

Finally, there are many ways to choose a saw blade. Some people will judge according to the appearance defects of the saw blade product, some will judge according to the saw tooth shape of the saw blade, and some will judge according to the material of the saw blade. In general, these methods are only based on some one-sided, not entirely correct.

How to observe the advantages and disadvantages of diamond saw blades with the naked eye?

Publish date:2022-11-29 14:05:55 Article From:LINSING diamond tools Clicks:

Vacuum Brazed Diamond Saw Blade

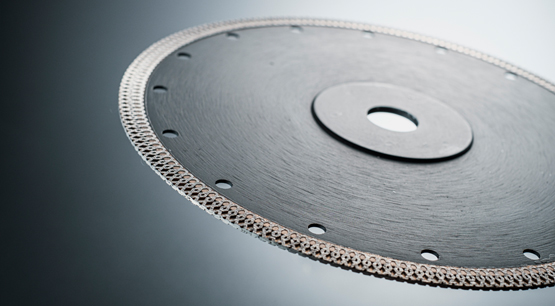

Continuous Rim Diamond Cutting Disc

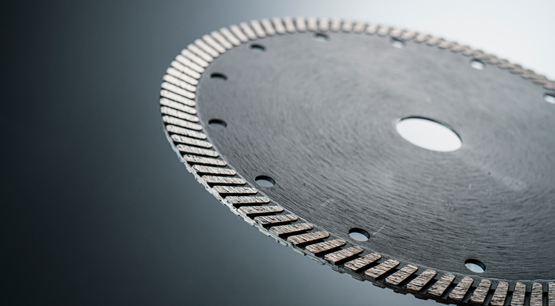

Turbo Cutting Disc

X Mesh Turbo Cutting Disc

Turbo Type Protection Teeth Cutting Disc

Related News

- Liquid phase sintering and solid phase sintering of diamond segment

- Hot pressing sintering technology of diamond segment

- What should do if the segment is moved grinding during the cutting process?

- Sintering process of Linxing diamond segments

- Important notice! 2020 Xiamen International Stone Exhibition will be postponed to October 27-30!