Anyone in the stone industry knows that with the development of science and technology. And Diamond segment products are constantly being updated, and the substrate of the saw blade is also constantly improving the process. Then, with the upgrade of the two decisive parts of the saw blade, the saw blade is also constantly developing, and slowly in The relationship between production cost and balance in quality control. How to reduce the production cost, is the current diamond saw blade manufacturers and Questions that stone manufacturers must consider. The requirements for the use of stone saw blades are analyzed as follows:

The requirements for the use of stone saw blades are analyzed as follows:

1. In order to improve the material yield and reduce unnecessary wear of the saw blade, please pay attention to the placement and reliable fixing of the blocks. During the use of the saw blade, there is often a deflection problem. Sometimes, the stone shakes during the cutting process. The main reason is that the stone is not fixed stably. This situation greatly increases the cost of saw blade replacement, which needs to be resolved as soon as possible.

2. Welding problem, you must use the appropriate welding solder in the process of welding the diamond segment, and choose an automatic welding machine with higher precision as much as possible. Especially if the sheet is relatively thin, the welding firmness can greatly increase the diamond segment and the service life of the saw blade, and can make the saw blade welding flatness and the smoothness of the diamond segment better, without causing damage to the plate, and greatly improve the service life of the saw blade.

3. When sawing, sparks are generated due to the strong impact and friction between the diamond segment and the stone to cause heat, and sufficient cooling water is required for cooling. Insufficient water will cause damage of the diamond segment , so it is necessary to ensure sufficient water supply without interruption. In terms of water flow, uniform water flow is more reasonable than concentrated water flow. But the water flow should not be too large, and cutting slippage will occur, which will reduce cutting performance. If slippage occurs, appropriately reducing the speed can also solve the problem.

4. Add lubricating fluid in time and quantity. Sufficient lubrication can reduce friction, reduce noise, improve productivity and prolong the service life of saw blades. Especially if there is a factory with a circulating water system, it can not only reuse the lubricant, reduce costs, but also protect the diamond segment and machinery.

5. When sawing stones of different materials, according to the change of the main motor current, please adjust the sawing depth and sawing speed in a timely manner. In other words, different stone materials require different cutting speeds and depths. It needs to be adjusted continuously based on the real-time performance of the saw blade cutting and the normal current value. So high cutting current means that cutting is difficult, and timely reducing the cutting depth can solve the problem. Don't blindly pursue high efficiency, but let the saw blade work under a long-term load, which will affect the cutting ability of the saw blade.

6. During the sawing process, pay attention to the change of the sawing sound and the change of the current at any time. If the diamond saw blade is abnormal, it should be eliminated in time. In particular, some obvious roaring sounds and harsh sawing sounds are relatively normal performances. At this time, we must quickly judge the current situation and find a solution.

7. Monitor the quality of the raw boards sawn out, and timely check and deal with the influencing factors according to the degree and quantity of the raw boards. There will be various problems in the process of stone cutting, and most of the problems will be seen from the cut plate. According to different cutting situations, find out the reasons and solve them. 8. When removing the saw blade for storage, in order to reduce deformation, it should be hung vertically. This can better protect the cutting segment and the saw blade body of the saw blade from bending damage. Many stone factories do not pay attention to this. If it is placed in this way for a long time, the saw blade is prone to bending and deformation.

8. When removing the saw blade for storage, in order to reduce deformation, it should be hung vertically. This can better protect the cutting segment and the saw blade body of the saw blade from bending damage. Many stone factories do not pay attention to this. If it is placed in this way for a long time, the saw blade is prone to bending and deformation.

Several points that should be paid attention to when diamond saw blades are cutting stone

Publish date:2022-11-29 14:49:09 Article From:LINSING diamond tools Clicks:

Vacuum Brazed Diamond Saw Blade

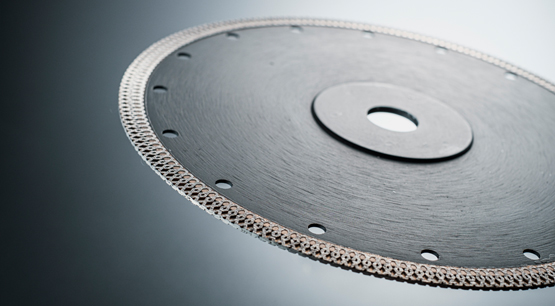

Continuous Rim Diamond Cutting Disc

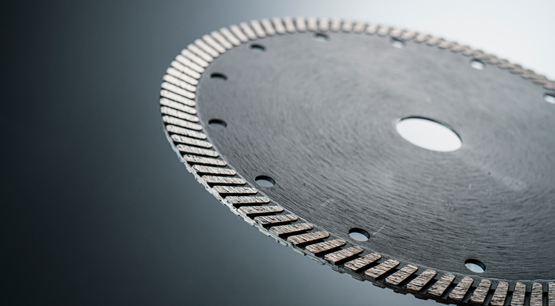

Turbo Cutting Disc

X Mesh Turbo Cutting Disc

Turbo Type Protection Teeth Cutting Disc

Related News

- Commonly used segment styles for granite 300-1000mm saw blades

- How to choose diamond circular saw blade and diamond segments?

- Introduction of ceramic saw blades and diamond segments used

- The difference between saw blade diamond segment and other diamond segment

- How to solder the diamond segment on the saw blade?