When choosing a diamond saw blade, according to the two components of the saw blade (diamond blade and saw blade), conduct separate observations and tests, and then make a comprehensive judgment based on the combination of the two. Let’s take a closer look for that:

First of all, let’s talk about the substrate. It is very important to select the substrate. If you had choose a poor quality, the saw blade will have problems such as deflection, bending, deformation, etc., and even some of the substrate may break, which threatens the operator’s safety. So we should pay special attention to the selection of the substrate. So what should be pay attention when choosing a saw blade?

First, the tension . The tension of the saw blade refers to the tensile ability and axial compression ability of the saw blade during the cutting process. Simply put, when the tension of the saw blade is large, the tensile ability and the axial compression ability of the saw blade becomes stronger and the cutting will be smoother. However, if the cutting speed is too high, the saw blade will be directly deformed due to excessive force due to the high bending resistance. When the tension is too small, which will cause a crooked knife, because during the cutting process of the saw blade, under a certain cutting speed, the saw blade has insufficient bending resistance. Of course, it is best to maintain a balanced tension overall select.

Second, the material of the saw blade substrate itself. There are many materials for the saw blade substrate, including high-speed steel, alloy steel, carbide steel, etc. The difference in the base will determine the strength of the saw blade. The saw blade with good strength can be used in the cutting process with quickly and take into account a longer service life, but the saw blades with poor strength, although the price is relatively cheap, usually have a short life, which leads to an increase in production costs.

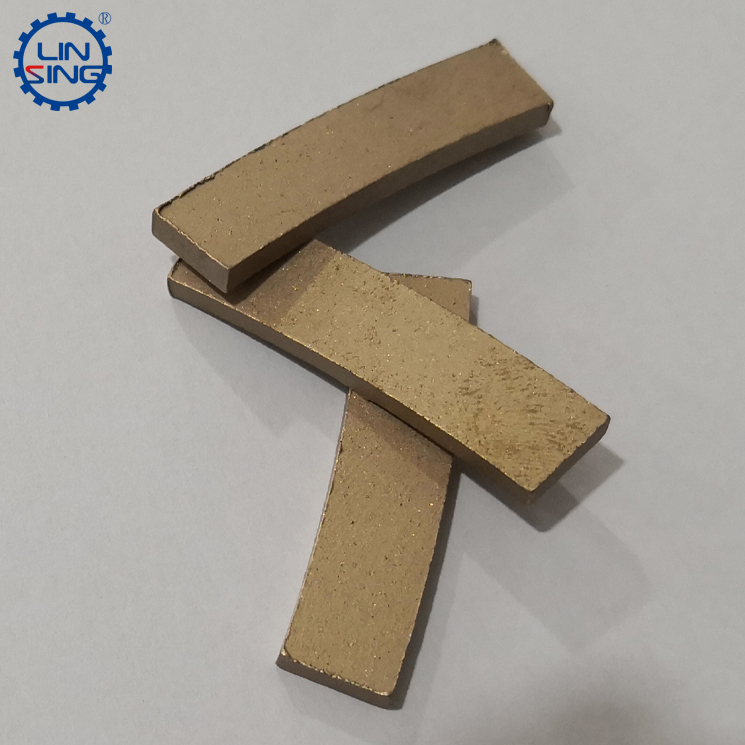

Next, let’s talk about the diamond segment. The diamond segment is the cutting part of the entire diamond saw blade, so it is especially important. Generally, we must pay attention to the following points when we choose the diamond segment:

First, matching the cutting material, the marble diamond segment and the granite diamond segment are completely different, and should not be confused.

Second, the diamond segment must have sharpness, and the service life can be adjusted continuously. For the stone cutting tool, the cutting movement is the most important factor of the diamond segment. there is no meaning if the sharpness is not enough, no matter how high the service life is.

Third, the density of the diamond segment is very important. The density determines the density of the diamond segment. Everyone knows that the higher the density, the stronger the diamond and the metal bond are combined. The density also determines the quality and stability of diamond segment.

Finally, introduce the saw blade composed of the diamond segment and the saw blade substrate, which should be paid attention to as a whole:

First, the diamond segment and the substrate are connected together by welding, so the welding process is extremely important, such as the material to be welded, the size of the weld, whether the diamond segment is horizontally symmetrical, whether the diamond segment is in a vertical state, etc. They all can affect the cutting performance of the entire saw blade.

Second, the welding strength. The welded segment should be knocked on the side. If it falls, it means that the welding strength of the segment is insufficient. On the contrary, the welding strength of the segment is sufficient.

Third, in the post-processing part, the diamond circular saw blade is in contact with water for a long time during the cutting process. The saw blade will definitely be oxidized. The oxidized matrix will not only affect the appearance of the saw blade, but also directly affect the cutting performance. So in the post-processing treatment, anti-rust treatment must be done.

In general, the selection of diamond circular saw blades is a very complicated and tedious process, but there are also traces to follow. If the detection is carried out, it is naturally easy to obtain saw blades with higher efficiency and longer life.

How to choose diamond circular saw blade and diamond segments?

Publish date:2022-07-07 17:46:10 Article From:Linsing Diamond Tools Clicks: