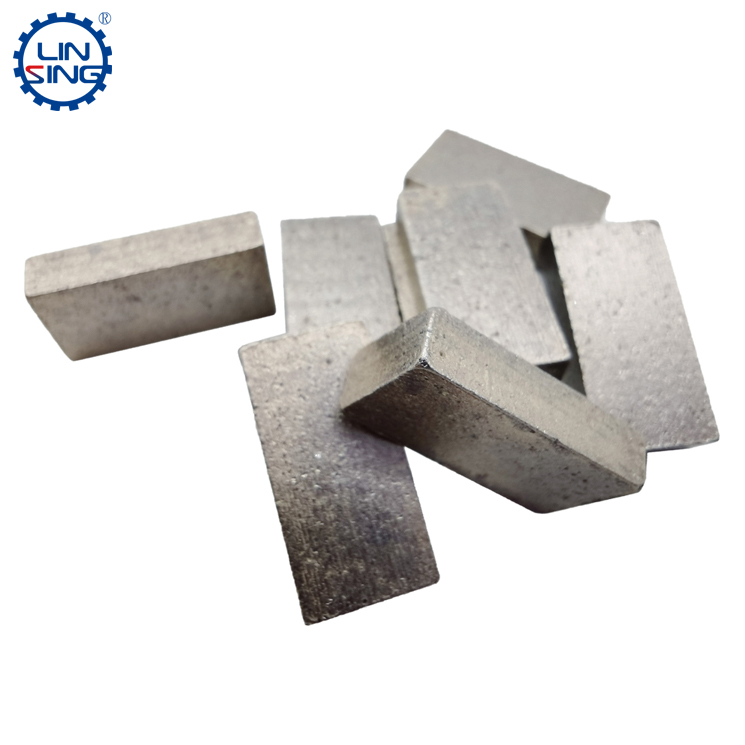

The diamond segment is welded to the circular saw blade to form a new diamond saw blade, which has the function of cutting hard materials. However, due to some skills in the welding process, many saw blades performance is not good during the welding process. Some segment will fall off while the saw blade only used for a very short time. What's more, the segment will be partially worn and the stone slab will be scratched. Therefore, the skill of welding the diamond segment is proficient in the diamond saw will have great help in the service life and the cutting effect.

So what should be paid attention to during the saw blade welding process? Below we list seven common welding techniques to help you improve the welding process and increase the welding strength of the segment.

1: In the welding material selection, if it is a marble segment, choose silver solder or silver copper solder as much as possible. If you choose copper solder, the difficulty of soldering the blade will increase and the welding will not be possible. For cutting granite, you can choose cooper lug for welding.

2: The choice of silver solder is determined by the hardness of the stone. For soft stone, the silver content of the silver solder can be maintained at 18%-35%. If you want to cut harder stone, it is best to choose the silver content with 35% of the silver solder lugs are used for welding, especially if customers choose cobalt-based segment, the 35 percent silver-containing solder lugs make the blade welding stronger and greatly improve the welding strength.

3: During the welding process, the high-frequency welding machine has the function of quickly heating up and maintaining the welding constant temperature. Compared with simple fire welding, it has great advantages, not only in the control of welding temperature and time, but also it will not have a big impact on the quality of the segment. However, fire welding, due to the temperature rise, it will effect the stability of the segment. Therefore, if possible, choose a high-frequency welding machine to complete the welding process of the segment as much as possible.

4: The most common way to remove the waste segment before welding is to quickly heat the segment, and then after the solder is melted, quickly peel off the waste segment. This peeling method is simple and quick, but this method often exists one problem is that the temperature is too low and the solder is not completely melted, causing the solder to continue to be adsorbed on the serrated surface of the substrate, which will have a bad effect on the subsequent soldering. The second is that the temperature is too high, which will cause the segment to fall quickly, which is easy caused a wounding situation. Therefore, the best way is to adjust the appropriate temperature and put the used segment in the recycling container, which greatly increases the safety.

5: In the welding process, the tooth-tooth welding will be better. In the saw blade welding process, the tooth-tooth welding is the most common method. The biggest advantage of this method is the fault tolerance rate. Even if the segment welding is somewhat skewed, when the teeth are separated, the saw blade can also be adjusted back. The specific operation of this method is that after welding a segment, separate a saw tooth for welding, wait until the welding is completed, turn the saw blade over, and continue to weld the other segments.

6: There will be flow of material during the soldering process. At this time, it is often caused by the too low melting point of the solder. At this time, the soldering temperature can be adjusted quickly, which can greatly avoid this situation. If there is still a large area of flow material, it can be avoided by speeding up the welding speed and reducing the welding time.

7: After the welding is completed, be sure to check the welding strength of the saw blade, use the clamp to move it, quickly find the weakly welded segment, quickly peel it, and then start the second welding.

Generally speaking, there are a lot of special attentions to the welding of the segment. In fact, there are a lot of contents in the operation part of many machines, especially for different welding methods, fire welding, high-frequency automatic welding machines, Semi-automatic welding machines and other machines have different skills, which will be introduced in detail in the future, but this article will not repeat them.

How to solder the diamond segment on the saw blade?

Publish date:2022-07-13 09:13:12 Article From:Linsing Diamond Tools Clicks:

Diamond Segment For Granite Cutting

Diamond Segment For Gang Saw

Diamond Segment For Sandstone Cutting

Diamond Horizontal Blade For Marble

Vacuum Brazed Diamond Saw Blade

Related News

- Several aspects to consider in diamond segment customization

- Diamond segment on diamond requirements

- Liquid phase sintering and solid phase sintering of diamond segment

- 70% diamond segment factory planning adjust price due to diamond powder price is increasing

- HOW TO CHOOSE THE BEST SUITABLE DIAMOND SEGMENTS