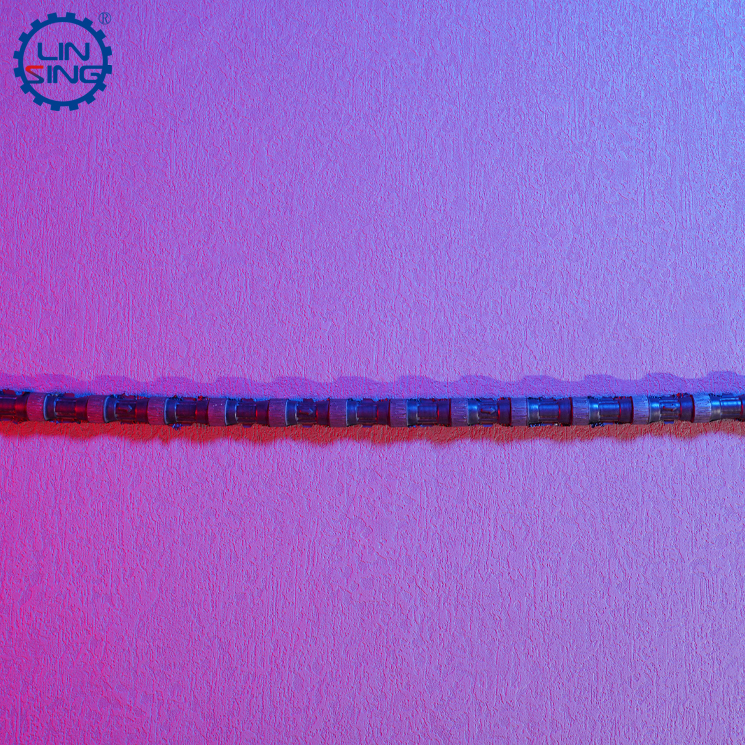

Diamond wire saws are often used in the mining of marble and granite mines. Due to the special processing environment of mines, a lot of preparation work needs to be done in the early stage of processing. Let's take a look at it in detail:

String

After the ore body is drilled, it is necessary to thread the rope. There are several ways to thread the rope:

⑴ strong magnet

Workers transport the wire saw from the vertical hole to the intersection of the horizontal holes, send the hose with a strong magnet at the top into the horizontal hole to absorb the wire saw, and then take out the rope end;

⑵ "pawl" grab

Firstly, Workers tie a number of convoluted nylon threads to one end of the rope saw, transport them from the vertical holes to the intersection of the horizontal holes, and then use a pawl to hook the nylon threads and pull out the rope head;

⑶ "Rat Escape"

Firstly, Workers catch a mouse and tie a strong nylon rope to the mouse's tail or legs, then put the mouse down from the vertical hole. Secondly workers pour water on the top of the vertical hole or tap hard, and the mouse takes out the nylon rope through the horizontal hole. Finally, Workers pull out the wire saw.

⑷ connecting rope

Before the wire saw is connected, it must be "preloaded", which is what we often call rope winding. The purpose is to allow the wire saw to generate spin during the cutting process, so that all parts of wire saw are evenly consumed; the "preload" rotation direction is counterclockwise. The total number of turns = the length of the wire saw (m) × 1.5~2.5 turns/m. For example, a 50-meter wire saw can usually be winded around 50*2=100 circles before use.

After the wire saw has been working for a period of time (such as cutting for 50h), the contact point between the wire saw and the stone can be changed by changing the number of loading turns to reduce eccentric wear. For example, 50 meters of wire saw winds 100 laps previously. And after a period of time, the number of laps can be changed to 120 or 80 laps. So under what circumstances will the number of turns of the rope be increased? If there is obvious eccentric wear on one side after the wire saw is cut, in order to make the other side work better, increasing the number of rope winding turns can significantly improve this situation. However, if the eccentric wear of the wire saw is not obvious, because the diameter of the wire saw beads decreases with the increase of the cutting amount. The diameter decreases, and the number of rope windings does not need too many to complete the cutting. In addtion, if the number of rope windings is too large, it will cost and increase the consumption of the wire saw. So normally, appropriately reducing the rope winding can also improve the cutting life of the wire saw.

The wire saw after "pre-loading" needs to be connected. The best distance of connecting point is about 3mm away from the bead, and the exposed wire rope in the middle is probably kept at About 10mm. Because the distance of two adjacent beads is 20mm, the distance of 10mm on both sides can make the joint tight, and also increase the connection strength of the diamond wire saw.

The diamond wire saw must carry out trial cutting during the working process. The trial cutting process is mainly to facilitate the adjustment of the angle, so that the cutting angle and the cutting surface correspond to the expected cutting surface. During the trial cutting process, the current should be as small as possible in a extent. Workers observe ehrther the flywheel and mechanical angles are correct and whether the height of the flywheel needs to be adjusted, etc.

Preparation work before mining of diamond wire saw

Publish date:2022-08-12 08:39:36 Article From:Linxing Diamond Tools Clicks:

Diamond Segment For Granite Cutting

Diamond Segment For Gang Saw

Diamond Segment For Sandstone Cutting

Diamond Saw Blade For Marble

Diamond Horizontal Blade For Marble

Related News

- Liquid phase sintering and solid phase sintering of diamond segment

- HOW TO CHOOSE THE BEST SUITABLE DIAMOND SEGMENTS

- Top 10 Mistakes in the Diamond Segments Selection Process

- Why The Diamond Segments Have Been Processed Into Vavious Shape?

- What should do if the segment is moved grinding during the cutting process?

Related Knowledge

- The Difference Between Dry And Wet Diamond Saw Blade

- How To distinguish Diamond Saw Blades From Appearance

- What Should We Do If The Diamond Saw Blade Is Lost Sharpness?

- Influence Of Diamond Particle Size On Saw Blade Performance

- Relationship Between Tooth Width Of Diamond Saw Blade And Blank Blade Thickness