In the process of stone processing, the choice of cutting tools is something that almost every operator must face. There are many issues to consider when choosing a tool. Accordingly there are many principles, such as the principle of efficiency, the principle of processing precision, the principle of stability, the principle of economy and so on.

First of all, let's talk about the principle of efficiency. The principle of efficiency is actually inseparable from other principles, especially the principle of economy. The main purpose of efficiency requirement is to ensure the economy of the entire process. Efficiency is particularly important. If there is no efficiency, in the case of the rapid development of modern industry, there will be no competitive advantage without efficiency. Especially as industrial products, such as diamond segments, saw blades and wire saws, efficiency determines almost everything. So separate it out and discuss it separately.

The principle of cutting efficiency is the first of all the efficiency under the premise of ensuring acceptable processing accuracy and acceptable stability. For instance, during the cutting process, the stone is seriously chipped, and the safety of the operator cannot be guaranteed during the cutting process. The saw blades of the saw blade will fly out and cut people at any time, and the cutting quality cannot meet the requirements. These are the core parts of efficiency. These are the core parts of efficiency. If there is no basic conditions for cutting, efficiency will be impossible.

Actually, It is not definitely determined that if the basic cutting effect is guaranteed, everything will go well. In most instances, in the sawing industry, efficiency and cost are in conflict. Most of the time, if you want to ensure the cutting life, you need to increase the price to ensure the cutting efficiency. For example, a saw blade costs $14. If the cost increases by 14% in order to increase the cutting efficiency by 10%, then the saw blade will cost $15.96 , which may no one like it.

The improvement of the cutting efficiency of diamond tools should also take into account production problems. For instance, a factory adds a certain step to the production process can improve the cutting efficiency of the saw blade, but this process requires higher costs and more time. The added process even needs a series of systems including production and quality inspection, then the improvement of cutting efficiency in this part will involve the conflict between production cost and actual value.

Finally, the principle of efficiency should also pay attention not to sacrifice other characteristics, such as lifespan of diamond segments which is particularly obvious in the diamond tool industry. The diamond tool of the same cost and process, if its cutting efficiency is improved, but at the same time, its life will be reduced. So Excessively reducing the life of the diamond segment is not the ultimate way to solve the efficiency problem, but a non-scientific way to improve efficiency.

From the perspective of efficiency-oriented tool selection, if the efficiency can be appropriately improved, and the cost is affordable, such tools can be selected. These tools are more frequently purchased by customers in developed Western European countries and North American countries.

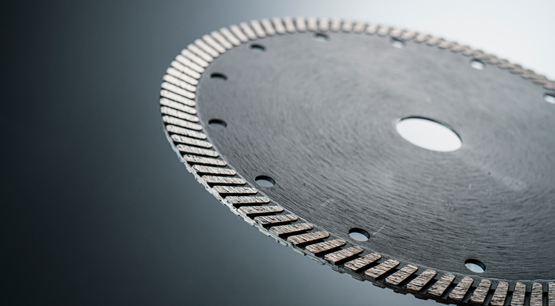

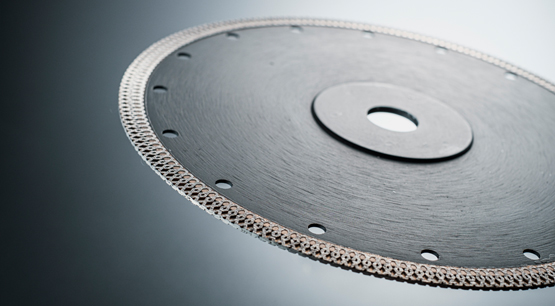

Principle of processing precision. The tools with processing precision are constantly developing, and the main market is the tools used for precision work. The added value of this kind of cutting tool is high, and the choice is mainly based on the cutting accuracy. The choice of this kind of tools are mostly water jet, saw blades, PCBN, PCD tools and so on.

In terms of stability, stability is the first choice. For example, cutting some expensive stones requires a tool with extremely high stability.

Economy means high cost performance, which is mainly for some daily products, such as diamond segments, small saw blades, wire saws, etc. And These product are mainly purchased by these countries and regions like Asia, Africa, etc.

In general, in today's increasingly competitive diamond tool market, choosing a suitable diamond tool to solve the cutting problem is a problem that every tone factory needs to consider. Diamond cutting tools account for a small proportion of manufacturing costs, and most of the manufacturing cost is in labor and management. If the cutting efficiency is increased by 20%, the manufacturing cost can be reduced by about 15%. But if you choose cost-effective products, the purchase price will be reduced by 20%, But in fact, the total manufacturing cost can only be reduced by about 2% . So in terms of the current market conditions and future tool trends, high-efficiency products are the future tendency of diamond tools, so as to minimize the production cost of enterprises and increase competitiveness.

Preferred parameters for selecting diamond cutting tools

Publish date:2022-09-01 16:01:14 Article From:Linxing Diamond Tools Clicks: