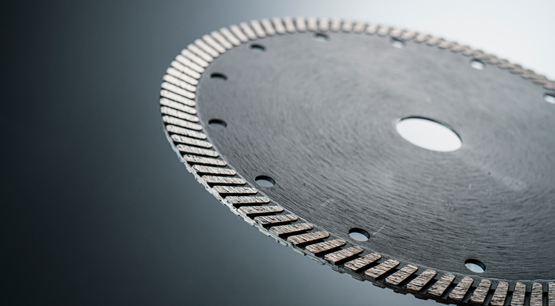

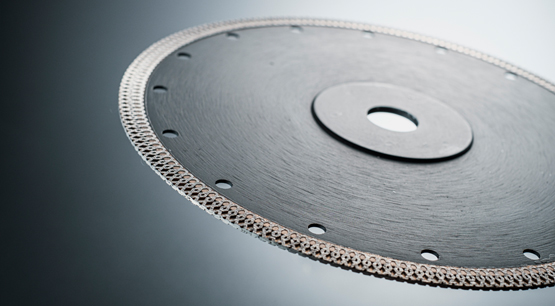

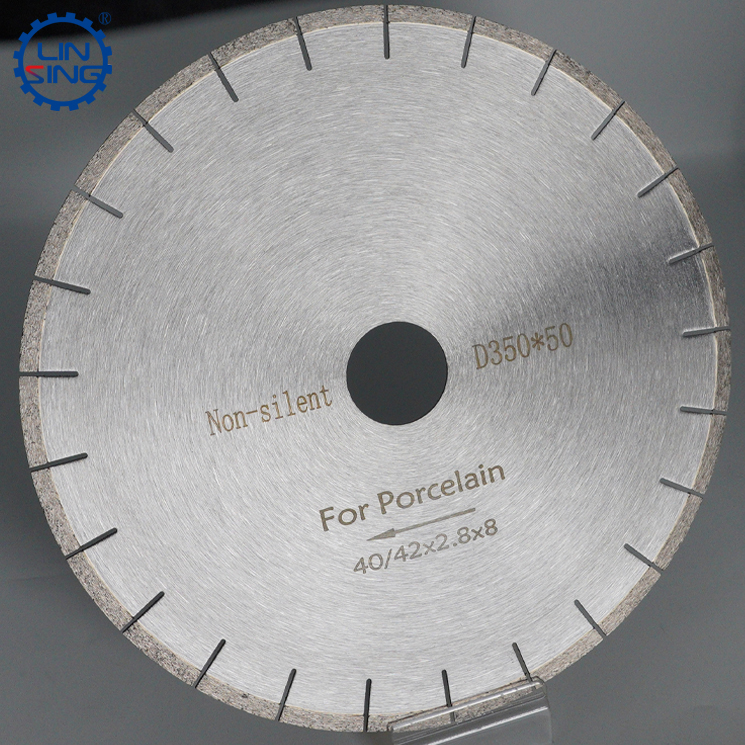

Diamond circular saw blade is a special cutting tool specially used for cutting granite, marble, concrete, refractory materials, glass, ceramics, pavement, graphite electrodes, reinforced concrete and other non-metallic materials. With the rapid development of the domestic stone and construction industry, the demand for diamond circular saw blades has increased rapidly. The key technology for manufacturing diamond circular saw blades is the chemical composition of the sawtooth part of the diamond segments and its corresponding manufacturing process.

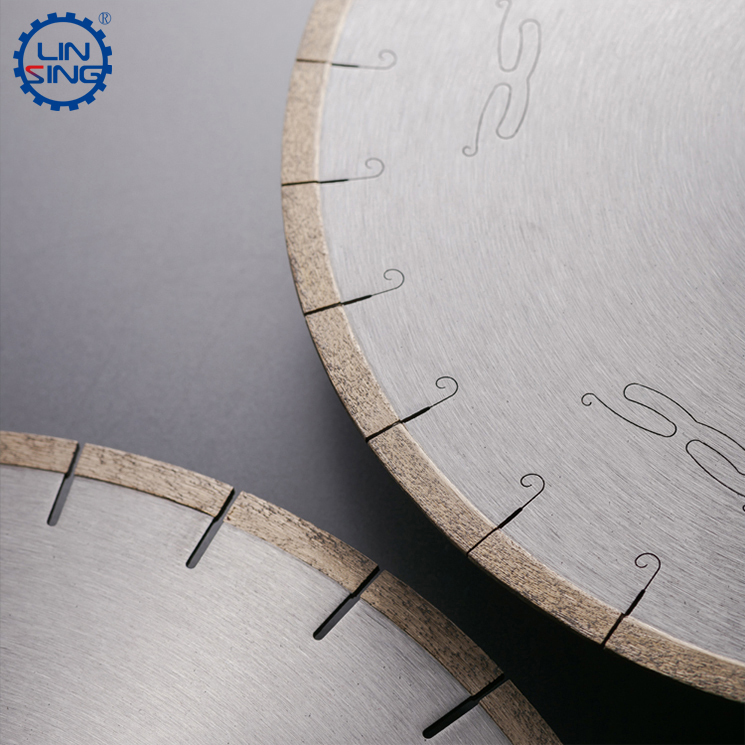

The composition of the diamond circular saw blade segment is divided into two parts. The first part is the diamond, which is the main part of the circular saw blade for cutting. The second part is metal powder, which is composed of various metal powders and some non-metallic materials (such as phosphorus, paraffin, etc.). The metal powder mainly plays the role of as skeleton, mainly through the alloy produced by the sintering work, so as to fix the diamond very well.

Most of the early diamond saw blades used cobalt bond diamond segments. In short, they are divided into low cobalt-based segments (cobalt powder content between 18-40%), ordinary cobalt bond segments (cobalt powder content between 40-60%) and high cobalt bond segments (cobalt powder content between 60-95%). All cobalt bond diamond segments (cobalt powder content above 95%). The cobalt bond segment has very good stability, no matter the wear resistance, stability or holding force for diamonds. So the price of diamond segments has remained high for a long time.

However, cobalt is a rare metal, and the reserves of cobalt in the world are not high. If it is used to make diamond segments in large quantities, the price of the segments will continue to rise. Eventually, due to the increase in the price of diamond tools, the price of stone has continued to rise. In order to change this situation, people began to use copper and iron materials to replace cobalt powder to produce copper bond segments and iron bond segments, hoping to keep the cutting ability of cobalt bond segments while continuously reducing production costs.

Soon, this innovation was realized. It was the copper bond segment that realized this change. At first, it was found that when copper powder was continuously added to the cobalt bond diamond segments, and the cobalt powder was appropriately reduced, there was also a good cutting effect.

When the cobalt powder content is continuously reduced and the copper powder has been increasing, the performance of the segment is continuously maintained. Because some iron powder and other metals will be added to decrease the impact of the reduction of cobalt powder. As for the iron bond segment, due to its great conflict with the performance of the cobalt bond segment, the iron bond segment with better wear resistance is more suitable for another process. Using iron bond segment to cut stone with high wear resistance (such as granite, quartz and other stones) has a very good cutting effect.

The innovative feature of copper bond diamond circular saw blades is to replace expensive cobalt with cheap copper and nickel. This process was vigorously developed in China in the 1990s. Copper-based diamond segments were completely freed from the influence of cobalt in later developments. By the beginning of the 21st century, copper bond segments and iron bond segments have become the same as cobalt bond segments, having become the raw materials for the commonly used diamond segment metal base formula.

Copper bond diamond circular saw blades have also been manufactured due to the appearance of copper bond diamond segments. The sintered copper bond diamond segment is welded or cold-pressed to the base of the saw blade, and finally a copper bond diamond saw blade for cutting stone or other hard materials is formed.

This kind of saw blade adopts advanced production technology, more scientific formula system and implements strict quality control, so that the product quality exceeds domestic similar products. In addition, the cost is lower than domestic and foreign similar products, and has obvious competitive advantages. Especially after 2010, copper bond diamond segments have almost become mainstream cutting tools, and are widely used in the cutting of marble, limestone, and some kind of granite.

In general, it is very important to use cheaper materials to reduce the cost of diamond segments, and more attempts will be made in materials in the later stage. While improving cutting efficiency, reducing the manufacturing cost is the future trend of diamond tool development.