In the process of making diamond segment, cold pressure is a very important process before sintering, especially cold pressure can make the powder molding of diamond segment, which is of great help to the molding of later processes.

Cold pressure is called cold pressure, first of all, in terms of temperature, to maintain a constant set of the best, especially in the process of cold press in the process of work, will heat, will also affect the effect of cold pressure, so the cold pressure workshop of diamond segment in the summer usually use air conditioning to cool down, so that the temperature remains below 20 degrees Celsius for the best.

Before the cold-press process, the working and non-working layers (also known as transition layers) of diamond blocks are weighed because the non-working layers are divided into iron sheets and powder alloys, so the non-working layers of iron sheets will avoid the weighing step. After weighing the working layer and the non-working layer separately, the next mixing and stirring is started, and the powder can be mixed evenly through the blender for a long time.

Mold inspection is a very important step, check the size and specifications of the mold, especially to detect whether the mold is intact, cannot appear broken and cracked situation.

Applying the release agent, because cold pressure is carried out at low temperatures, cold shrink diamond segment in the mold is difficult to release, applying the appropriate amount of release agent will make the diamond segment in the release process more easily, to prevent bonding.

Molding, now the cold press is mostly automated work, the installation of molds become simple, the mold into the cold press in the mold slot can be.

Loading, mixing good powder into the feed warehouse, respectively, the working layer and non-working powder by scraping flat and flattening with the pressure head, thus starting the production of the cold pressure process of the diamond segment.

The pressure is maintained so that the working and non-working layers of the diamond segment are thoroughly formed.

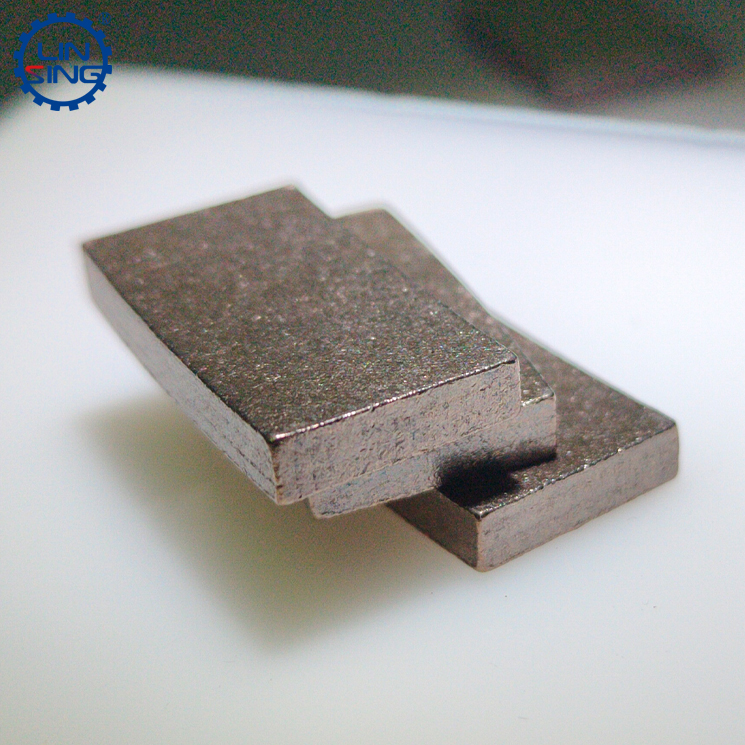

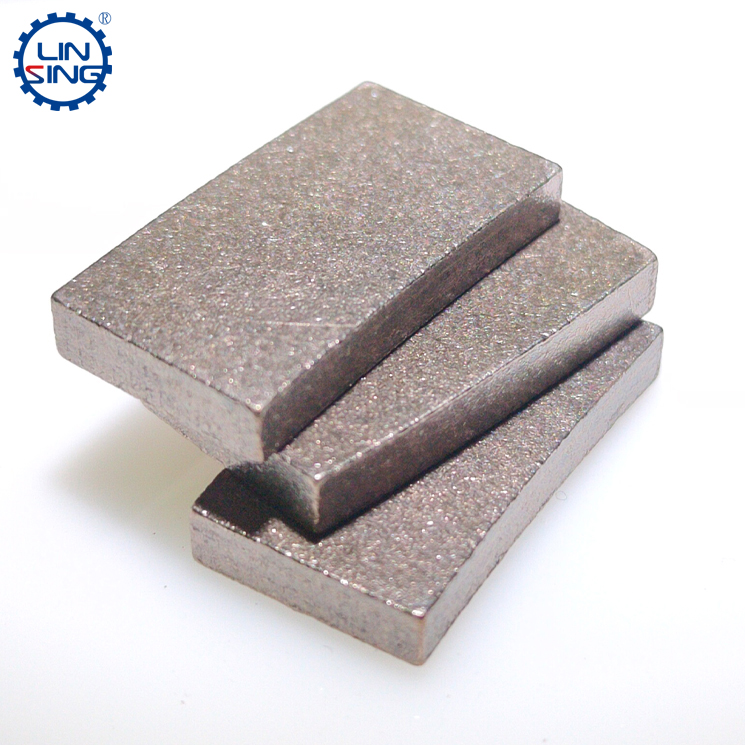

Impressing and unloading molds, automated cold-pressing opportunities to process mold-set head working layers and non-working layers of the lumps, and finally out of the molded solids.

Outline of the cold pressure process of the diamond segment

Publish date:2022-07-06 11:49:50 Article From:Linsing Diamond Tools Clicks:

Diamond Segment For Granite Cutting

Diamond Segment For Gang Saw

Diamond Segment For Sandstone Cutting

Diamond Horizontal Blade For Marble

Vacuum Brazed Diamond Saw Blade

Related News

Related Knowledge

- Influence Of Diamond Particle Size On Saw Blade Performance

- Relationship Between Tooth Width Of Diamond Saw Blade And Blank Blade Thickness

- Installation Methods Of Diamond Saw Blade

- Introduction Of Common Parameters Of Diamond Saw Blade

- The Relationship Between Wear Resistance And Efficiency Of Diamond Saw Blades