Diamond beaded rope is a stone mining tool that has gradually become popular in recent years. This tool has many advantages, such as reducing noise, reducing pollution, maximizing the use of stone resources, small cutting gap, smooth cutting surface, easy processing, no Limited by the site, small cutting machine, and cutting surface large, so many people hope to use the beaded wire saw to mine stone. What is the specific process? This article will give a detailed introduction.

1. purchase of proper diamond wire saw

1) There are many kind of diamond wire saws. When buying a wire saw, you must meet the following conditions:

If there is a need to cut a large surface, you can buy a bundle of 100 meters instead of a wire saw of a bundle of 50 meters.

2)It is necessary to know what kind of stone to cut, and to understand the hardness and abrasiveness of the stone, so that it is convenient to buy a suitable wire saw.

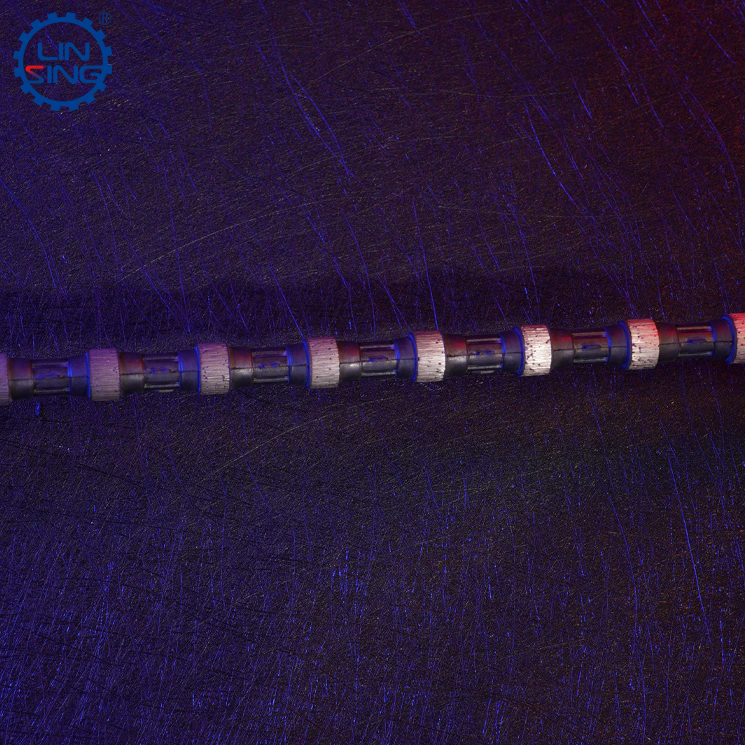

3)The thickness of the beads for mining stone is mostly 10.5mm, 11mm, 11.5mm, 12mm, of which the last three are mostly the size of granite mining rope, while the first three are mostly the size required for marble minin. The diameter of the bead is not as large as possible, because the smaller the diameter, the lower the bead cutting efficiency. The larger the diameter means the larger the cutting surface, which is not conducive to the cutting of the wire saw, but the stability will be stronger. In conclusion it should be selected according to the actual situation.

4)It is necessary to ask how many beads per meter, the more beads, the worse the sharpness and the better the lifespan; and the fewer beads, the better the sharpness, but the life of the wire saw will decrease. The more beads are in one meter, the higher the price.

2. The selection of wire saw machine placement.

In terms of determining the position of diamond wire saw machine, the placement position needs to have the following characteristics In order to perform better cutting.

1)It is should be ensured that only one or two sides of the wire saw are cut as much as possible, instead of all the surfaces in contact with the stone participating in the cutting, which will greatly reduce the cutting efficiency.

2)It should be ensured that the guide wheels are easy to install, and the reasonable use of the guide wheels can greatly speed up the cutting efficiency of the wire saw. If the selected position is reasonable, the guide wheels will speed up the work progress faster.

3)The selected place must be flat, and the uneven place cannot be selected. Even if it is not flat, the ground needs to be leveled before the cutting starts, and the position that does not have the possibility of leveling cannot be selected.

3. Drilling

The vertical and horizontal planes of the mine are drilled separately through the down-the-hole drilling. The final result of the drilling is to connect the vertical plane and the horizontal plane, which is convenient for later threading, and also ensures chip removal and cooling during the later wire saw cutting process. effect.

4. The installation of guide wheels

Reasonable use of guide wheels can make cutting more efficient, but simplifing the number of guide wheels as much as possible in order to reduce the time for installing guide wheels and reduce cutting time is necessary. The discharge of the guide wheel needs to be supported by long-term cutting experience.

5. String

Workers should pass the wire saw from top to bottom through the vertical and horizontal holes, as well as the guide wheel, flywheel.

6. Cutting

Worker use hydraulic pliers to cut the rope saw.It needs to pay attention to trying to cut the middle part of the bead and the bead, not to one side, which can facilitate the later knotting of the rope.

7.Roping

According to the length of the wire saw, workers should choose the number of Rope times. Generally speaking, dividing the length by 2 is the number of rope times. Of course, if cutting soft stones, the number of rope times can be appropriately reduced, depending on the actual cutting situation. It should try to choose both sides to circle at the same time during the winding process, , instead of choosing one side to circle and one side to not circle.

8.knotting rope

The wire saw is tightly connected by hydraulic clamps and joints. In this process, you need to pay attention to whether there is a size problem at the connection size.

9. The adaptation of track and machine

Workers should adjust the track and the wire saw machine to the appropriate position, ensuring that the wire saw faces the cutting gap vertically. If there is a guide wheel, facing the guide wheel vertically. Workers should move the wire saw to the front of the track before turning it on.

10. Booting

The last step is boot and start cutting

There will be many problems in the wire saw cutting process. Later, Linxing Diamond Tools Co., Ltd. will bring you a more detailed introduction.