During the working process of the diamond saw blade, the cutting depth largely represents the cutting efficiency, but it does not depend entirely on this, because the cutting efficiency of the saw blade is the number of squares of stone cut per unit time, and the cutting depth is only the height. In terms of length, when the cutting depth is increased, the cutting speed will also slow down. Therefore, the two factors of the cutting depth and the cutting speed of the saw blade affect the cutting efficiency of the saw blade, and adjusting the cutting depth is largely a In order to improve cutting efficiency. Is changing the depth of cut just to improve cutting efficiency? Not so. In many cases, changing the cutting depth can solve many complex situations faced by the site. Let’s take a closer look at when it is necessary to change the cutting depth and how to adjust the cutting depth and other related content.

Is changing the depth of cut just to improve cutting efficiency? Not so. In many cases, changing the cutting depth can solve many complex situations faced by the site. Let’s take a closer look at when it is necessary to change the cutting depth and how to adjust the cutting depth and other related content.

1: The degree of softness and hardness of the stone has changed, and the cutting depth needs to be adjusted. Generally speaking, the softer the stone, the deeper the cutting depth can be adjusted. Under normal circumstances, in the process of cutting marble blocks, if a single saw is used, the cutting depth can reach 5-10 cm. As the hardness of the stone increases, the cutting depth needs to be continuously reduced. For example, when cutting medium-hard granite blocks, the cutting depth needs to be controlled at 1-2 cm. If it is harder granite or quartz stone, the cutting depth needs to be further reduced. A cutting depth of 0.5 cm is more reasonable. It should be noted that the power, newness and stability of the machine also have a greater impact on the cutting depth of the stone.

2: The abrasiveness of the stone has changed, and the cutting depth needs to be adjusted. When the cutting segment of the saw blade encounters highly abrasive stone during the mixed stone cutting process, the cutting depth needs to be adjusted. Generally speaking, the more abrasive the stone, the smaller the cutting depth needs to be adjusted. The stone should be cut thoroughly during the process, otherwise the motor current will be increased, resulting in various problems in cutting. Generally speaking, sandstone with the same Mohs hardness level has a light cutting depth than marble.

3: Under normal cutting speed, the segment is consumed too quickly, and the cutting depth needs to be adjusted. This situation is mainly due to the fact that the cutting speed and cutting speed of the saw blade are relatively normal during the process of cutting stone blocks, but the cutting segment of the saw blade is consumed too quickly. The forward force of the blade acts on the smaller stone cutting surface. At this time, the diamond segment bears a greater impact force and is prone to breakage. This abnormal breakage will cause the segment to be consumed too quickly, resulting in a large Significantly reduce the cutting life of the segment. If you encounter this situation, you can increase the cutting depth appropriately to make the diamond of the saw blade work more normally. Of course, appropriately reducing the cutting speed can also solve the current problem, but it reduces the cutting efficiency.

4: Under normal cutting speed, the segment becomes blunt, and the cutting depth needs to be changed. When the saw blade is cutting stone, it is inevitable that the segment will become blunt. The main reason is that the segment will rub against the stone for a long time during the cutting process, but the cutting surface is too large, which makes the diamond unable to break. There is also a state that is completely opposite to the third situation above. The diamond cannot be broken. Over time, due to the grinding of the cutting edge, it will not be able to cut the stone, slip and so on. In this case, properly reduce the cutting depth and increase the cutting speed, and slowly the diamond will start to re-emerge, and the problem will be solved. In general, the adjustment of the cutting depth of the diamond segment is not based on a single parameter, but needs to be considered in combination with many different situations, and finally a better adjustment scheme is carried out. The most important thing is to ensure the cutting quality while taking into account the cutting life and cutting efficiency, so that the segment can play a better role, helping stone processing enterprises to reduce production costs and improve stone production and processing capabilities.

In general, the adjustment of the cutting depth of the diamond segment is not based on a single parameter, but needs to be considered in combination with many different situations, and finally a better adjustment scheme is carried out. The most important thing is to ensure the cutting quality while taking into account the cutting life and cutting efficiency, so that the segment can play a better role, helping stone processing enterprises to reduce production costs and improve stone production and processing capabilities.

How to adjust the cutting depth of diamond segment

Publish date:2023-01-06 15:43:36 Article From:LINSING diamond tools Clicks:

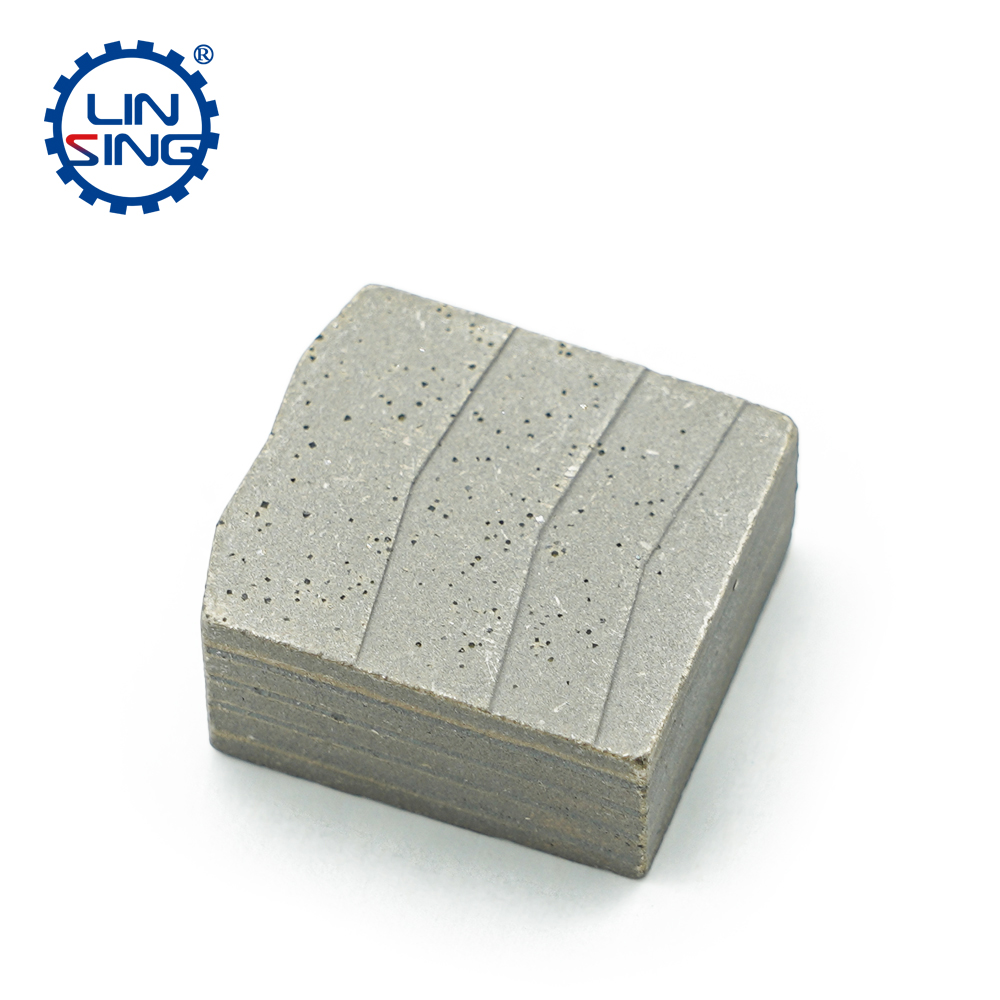

Diamond Segment For Granite Cutting

Diamond Segment For Gang Saw

Diamond Segment For Multi-Saw Blade

Diamond Segment For Sandstone Cutting

Diamond Horizontal Blade For Marble

Related News

- Liquid phase sintering and solid phase sintering of diamond segment

- HOW TO CHOOSE THE BEST SUITABLE DIAMOND SEGMENTS

- Top 10 Mistakes in the Diamond Segments Selection Process

- Why The Diamond Segments Have Been Processed Into Vavious Shape?

- What should do if the segment is moved grinding during the cutting process?

Related Knowledge

- Influence Of Diamond Particle Size On Saw Blade Performance

- Relationship Between Tooth Width Of Diamond Saw Blade And Blank Blade Thickness

- Installation Methods Of Diamond Saw Blade

- Introduction Of Common Parameters Of Diamond Saw Blade

- The Relationship Between Wear Resistance And Efficiency Of Diamond Saw Blades