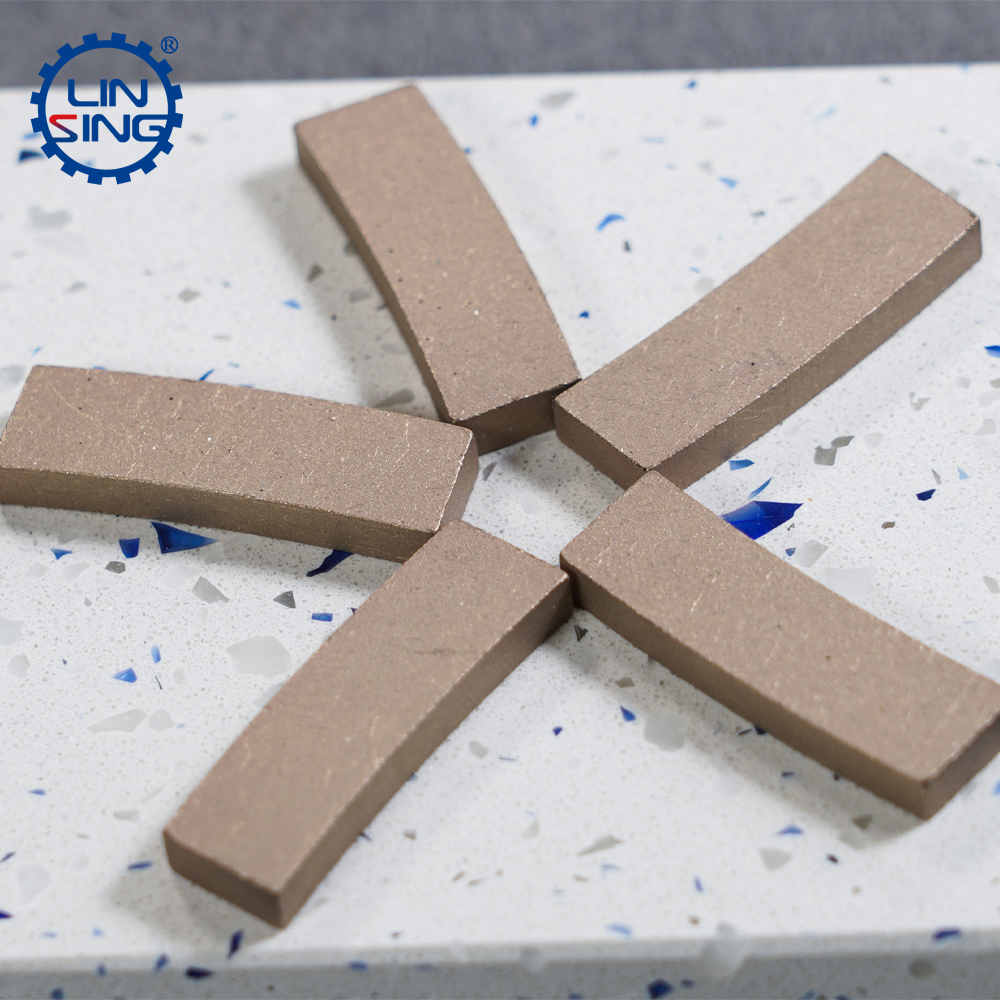

Natural stone is a material that people often choose in home decoration. However, due to many reasons, during the installation and splicing of stone materials, problems such as uneven height, uneven assembly, and length and width errors often occur. These problems will lead to the need for secondary processing of stone materials for engineering installation, and most of the secondary on-site processing cannot solve the defect problem well, which will lead to a decline in project quality, and eventually lead to legal disputes and liability disputes. What everyone doesn't know is that all of these, in the final analysis, are caused by insufficient machining accuracy of the diamond segment. The problems with the machining accuracy of the diamond segment are mainly reflected in the following aspects: the first is that in the process of slate cutting, if the blank blade and the segment are welded correctly, there will still be differences in thickness. Secondly, in the process of cutting the edge of the stone, with the assistance of the infrared alignment line, the size of the plate will still be inaccurate, and the error will exceed 0.5mm. Thirdly, during the use of the segment, the accuracy error of the plate is caused by various problems.

The problems with the machining accuracy of the diamond segment are mainly reflected in the following aspects: the first is that in the process of slate cutting, if the blank blade and the segment are welded correctly, there will still be differences in thickness. Secondly, in the process of cutting the edge of the stone, with the assistance of the infrared alignment line, the size of the plate will still be inaccurate, and the error will exceed 0.5mm. Thirdly, during the use of the segment, the accuracy error of the plate is caused by various problems.

So what is the reason that affects the machining accuracy of the diamond segment after we get the knowledge of accuracy situation? If the following six points can be done well, the machining accuracy of the diamond segment can be greatly improved. It can also help stone cutting manufacturers and employees to greatly improve production efficiency, reduce environmental pollution caused by secondary processing, provide customers with more satisfactory natural stone products, reduce defects and smoothen conflicts.

1. The cutting problem caused by the mixing problem during the diamond segment production process. Mixing the raw material is the first step in the segment manufacturing process, and it is also a very important step. If this step is not done well, there will be more serious problems in other steps later. The first thing to bear the brunt is the obvious difference in the degree of consumption of the segment and the location of the consumption. Such a difference will cause uneven force on the entire saw blade during the cutting process. And this kind of uneven force will affect the end jump and radial jump of the substrate to a certain extent, and even the flatness of the whole sheet will be affected, which will lead to serious cutting problems of the sheet. To be precise, there will be problems such as excessive deviation of the cutting accuracy of the segment, excessive or uneven stone cutting seam, etc.

2. Cutting problems caused by weighing during the cold pressing of the diamond segment. Since the current powder granulation technology is eliminated, it is found that the powder is in the process of cold pressing. Due to the humidity of the powder, the uniformity of the powder, the peeling of the cold-pressed tablet, etc., there will be a difference in the weight of the powder of the same volume, which is a typical situation of uneven density. If such a cold-pressed sheet is used to process the finished segment. Due to the different weights of the diamond segment, the centrifugal force will deviate when the saw blade rotates at high speed. The most direct manifestation is that the diamond segment will cause huge problems in stone cutting due to the centrifugal force and slight deviation. The specific performance is: Uneven cutting and edge chipping occur frequently.

3. The problem of the size of the segment caused by the multiple use of the abrasive tool during the sintering process. In the sintering process, graphite abrasives are often used, which mainly play the role of electrification and better setting. However, during the sintering process, the carbon of graphite will be oxidized. Over time, that is, after the graphite abrasive is reused for 3-6 times, the size of the graphite abrasive will vary greatly. It is directly manifested in the size difference of the segment, and the surface of the segment is obviously uneven. Such a diamond segment cutting stone, the problem of insufficient precision will definitely appear. 4. Cutting problems caused by random matching of segments. In the process of using the segment, many factories will match the segment according to the needs in order to achieve the effect of fast cutting or prolonging the cutting life. For example, some factories will weld a part of the A segment, and then mix it with the B segment. The A segment has the characteristics of long life, and the B segment has the characteristics of high sharpness. This combination has good cutting efficiency and also takes into account the service life. It seems a perfect combination, but in fact there is a big quality hidden danger. For example, different segments have inconsistent temperature requirements for welding materials, and the welding strength will also vary greatly. Secondly, whether the thickness and weight of the segment can be solved during the welding process. Third, it is also a matter of diamond differences. Cutting will cause one of the segments to be consumed quickly and the other segment to be consumed slowly, which will increase the uncertainty of the segment. In general, there is no optimal operation plan for cutting stone with the segment, but random mixing of the segment for cutting will greatly increase the accuracy error in the stone cutting process.

4. Cutting problems caused by random matching of segments. In the process of using the segment, many factories will match the segment according to the needs in order to achieve the effect of fast cutting or prolonging the cutting life. For example, some factories will weld a part of the A segment, and then mix it with the B segment. The A segment has the characteristics of long life, and the B segment has the characteristics of high sharpness. This combination has good cutting efficiency and also takes into account the service life. It seems a perfect combination, but in fact there is a big quality hidden danger. For example, different segments have inconsistent temperature requirements for welding materials, and the welding strength will also vary greatly. Secondly, whether the thickness and weight of the segment can be solved during the welding process. Third, it is also a matter of diamond differences. Cutting will cause one of the segments to be consumed quickly and the other segment to be consumed slowly, which will increase the uncertainty of the segment. In general, there is no optimal operation plan for cutting stone with the segment, but random mixing of the segment for cutting will greatly increase the accuracy error in the stone cutting process.

5: Processing accuracy problems caused by welding problems. The quality of the welding directly determines the flatness of the saw teeth of the saw blade, so the flatness of the saw blade must be rechecked and tested before the saw blade is put on the machine.

6: Processing problems caused by mechanical problems. This problem mainly occurs on machines with relatively old machines and relatively small motor power. Due to the vibration of the mechanical engine, the diamond segment has a cutting problem. The improvement measures are also very simple. It can be solved by replacing the machine with higher power, newer style and better quality.

Six elements that determine the machining accuracy of diamond segments

Publish date:2023-01-06 15:24:49 Article From:LINSING diamond tools Clicks:

Diamond Segment For Granite Cutting

Diamond Segment For Gang Saw

Diamond Segment For Sandstone Cutting

Diamond Horizontal Blade For Marble

Vacuum Brazed Diamond Saw Blade

Related News

- Several aspects to consider in diamond segment customization

- Diamond segment on diamond requirements

- Liquid phase sintering and solid phase sintering of diamond segment

- 70% diamond segment factory planning adjust price due to diamond powder price is increasing

- HOW TO CHOOSE THE BEST SUITABLE DIAMOND SEGMENTS

Related Knowledge

- Influence Of Diamond Particle Size On Saw Blade Performance

- Relationship Between Tooth Width Of Diamond Saw Blade And Blank Blade Thickness

- Installation Methods Of Diamond Saw Blade

- Introduction Of Common Parameters Of Diamond Saw Blade

- The Relationship Between Wear Resistance And Efficiency Of Diamond Saw Blades