With the development of the world stone industry, stone processing technology has also made long-term progress. In the early days, people used large and thick saw blades to cut stone. At present, due to the development of the times, light and thin stone processing tools are more popular. It is because this saw blade has a fine saw seam, which saves materials and greatly improves the processing efficiency. Although ultra-thin saw blades have many benefits, people often encounter some problems.

The increase of the saw blade end vibration is the biggest reason for the thinning of the saw blade body. The reason for this is very simple. When the thickness of the saw blade base is reduced, the weight of the saw blade becomes lighter, which leads to an improvement in the bending performance of the saw blade and a significant decrease in rigidity. So it is easy to induce lateral vibration, that is, end vibration. The increase of the end vibration amplitude has produced many unfavorable factors, which will be explained in detail below:

1: The life of the saw blade will decrease. If the diamond circular saw blade is in the end-jump state for a long time during the cutting process, the cutting angle of the saw blade will change continuously. As the cutting depth increases, the pressure on the blade body will increase. There are two reasons for the increase.

Since the saw blade does not cut vertically, that is to say, it is difficult to ensure that the saw blade is strictly perpendicular to the stone block due to the cutting state of the saw blade. Therefore, during the high-speed rotation of the diamond circular saw blade, the transverse vibration of the traveling wave will occur, resulting in axial deformation. Axial bending waves appear at the outer edge of the saw blade, and the bending waves directly affect the cutting results of the saw blade. Such a situation will directly lead to a certain degree of distortion of the grinding teeth around the radius of the circular saw blade when the waveform rotates, and the saw blade body will be twisted for a long time.

During the processing, due to the brittleness of the stone, a certain amount of hard particles will be generated during the grinding process, and the saw blade will be squeezed in the sawing seam, causing the saw blade to produce a small lateral deflection, and the cutting force will continuously rotate along the circumference. The contact force between the chip and the saw tooth becomes the lateral vibration excitation force, which can only occur in the cutting arc area, In other words, the friction between these debris and the saw teeth also increases the end vibration of the diamond saw blade, aggravates the degree of twist of the saw blade, and reduces the life of the saw blade.

2: The saw seam is not straight. In the simplest terms, it is the unevenness of the slab, which is actually the follow-up effect after the saw blade is bent. This situation directly leads to the low quality of the cut slab, the Inconsistent upper and lower widths, and the low flatness. In the later stage, the slab needs to be ground and polished for a longer time, which increases the processing difficulty and reduces the processing efficiency. If there is a situation where the straightness of the saw seam directly affects the use, it will also cause a great waste of the slab, waste stone resources, and at the same time have an impact on the environment.

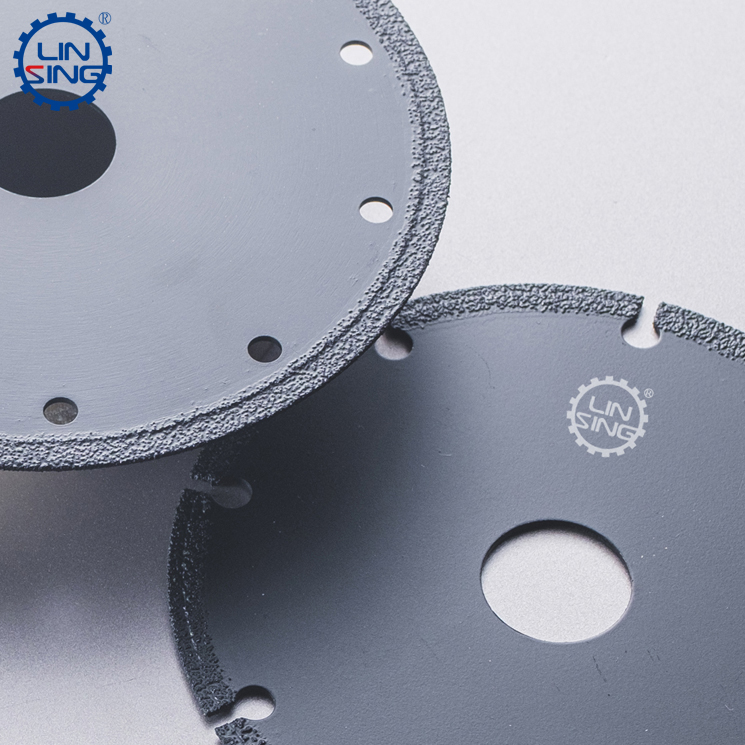

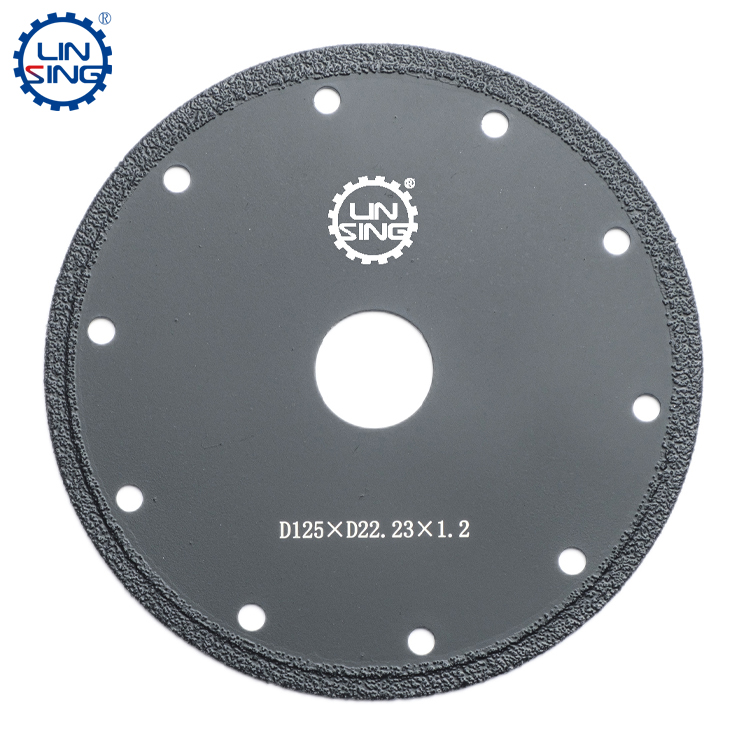

3: Higher requirements are needed for the diamond segment, replacing the segment with high sharpness. The ordinary segment is no longer available. When the ultra-thin saw blade is cutting stone, once the cutting process does not move the stone, the impact is very large, mainly because the saw blade is thin, and some problems are prone to occur during processing. So in order to maintain better cutting efficiency of the segment, it is very important to improve the sharpness of the segment.

4: The quality requirement of the saw blade steel body is higher. Although the thickness of the base material used in the ultra-thin saw blade is reduced, due to the rigidity requirement of the saw blade, actually, the purchase cost of the saw blade base currently used is not high. There is no reduction, but the procurement cost is increased due to the adoption of a new saw blade body process.

5: Higher quality requirements for operators. The ultra-thin sheet body makes it clearer for the operator to understand the machine and the cutting state, such as various states during the cutting process of the segment, the sound produced, the performance of the performance, the current power data, etc., all of which require on-site personnel to be more precise.

In general, although the ultra-thin combination saw blade is very good for cutting blocks, it still has high requirements in all aspects, especially the training of personnel, which requires a lot of effort to improve processing technology and be serious and responsible, be careful and clear.

Common problems encountered in the process of sawing stone with ultra-thin saw blades

Publish date:2022-09-05 11:53:30 Article From:Linxing Diamond Tools Clicks: