The silicon carbide in the diamond segment is currently widely used in stone grinding. In cutting, it is rarely used, mainly because silicon carbide has good wear resistance. In the polishing process, slow processing is possible. But when it comes to fast cutting, silicon carbide is not as good as diamond. And in the research and development of large-particle tungsten carbide, no major breakthrough has been made, so at present, diamond is still the main material for diamond blades for stone cutting.

This article mainly introduces the application of silicon carbide in diamond segment. What kind of segments need to use silicon carbide? What are the advantages and disadvantages of silicon carbide-based segments?

There are two main types of silicon carbide, the first is black silicon carbide, and the second is green silicon carbide. Among them, black silicon carbide contains 97% of silicon carbide, which has more applications in diamond blades for stone processing. The green silicon carbide contains about 95% silicon carbide, which is mainly used for polishing products, such as resin polishing and buff polishing products. This article mainly introduces black silicon carbide products.

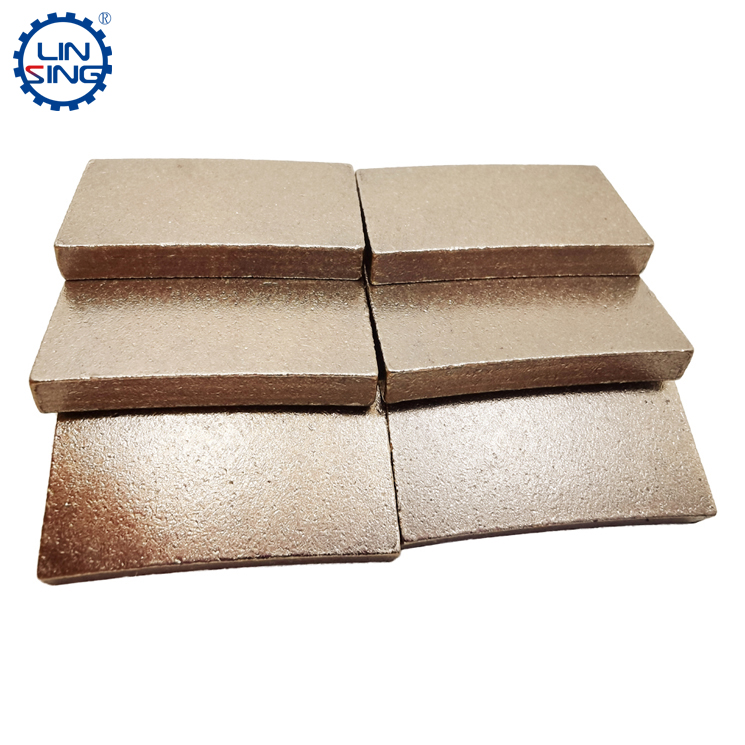

The silicon carbide segment is used for fine grinding of the segment. This fine grinding segment is a kind of segment used on the metal grinding disc. The size of the segment is 8 or 10 inches (200mm or 250mm), and the grain size is mainly 240# , 280#, 360#, etc., these particle sizes are difficult to take into account the common diamond grinding discs, and the addition of silicon carbide to these segments can significantly improve the rough grinding effect of the stone, and provide more for the fine grinding and polishing of the later stone. Good machined surface.

Silicon carbide segments can also be applied to CNC edging wheels. The advantage of this is that the particle size of the edging wheels can be more abundant, and in terms of abrasiveness, the particle size from 240 to 10,000 can meet the grinding and grinding of different stones. Polishing is widely used in edge processing.

Finger drills also need to use silicon carbide. Putting silicon carbide material into the finger drill bit can greatly enhance the grinding force of the finger drill, improve the efficiency of the finger drill, and increase its service life. The data shows that adding carbonization Silicon finger drills are 20% more efficient than those without silicon carbide, and their lifespan is increased by more than 10%.

Silicon carbide segments can also be used in stone carving . The fineness of the engraving bit can make the carved products more charming, especially the diamond segments containing silicon carbide, which abrasiveness is greatly increased, and the polishing degree and polishing effect are also getting significant improvement.

For the cutting of steel, if only diamond is used, the effect is not good. Silicon carbide has a very strong cutting force for cutting steel-concrete materials or individual steel-reinforced materials. Therefore, carbonization is added to the current road blades and medium and large concrete saw blades.

In general, silicon carbide is widely used in diamond segments, mainly to assist in grinding, prolong cutting life, improve stone processing efficiency and improve the polishing effect, etc., add appropriate carbonization to the diamond segment formula Silicon can play an unexpected role.

Application of Silicon Carbide in Diamond Segment

Publish date:2022-07-12 19:43:43 Article From:Linsing Diamond Tools Clicks: