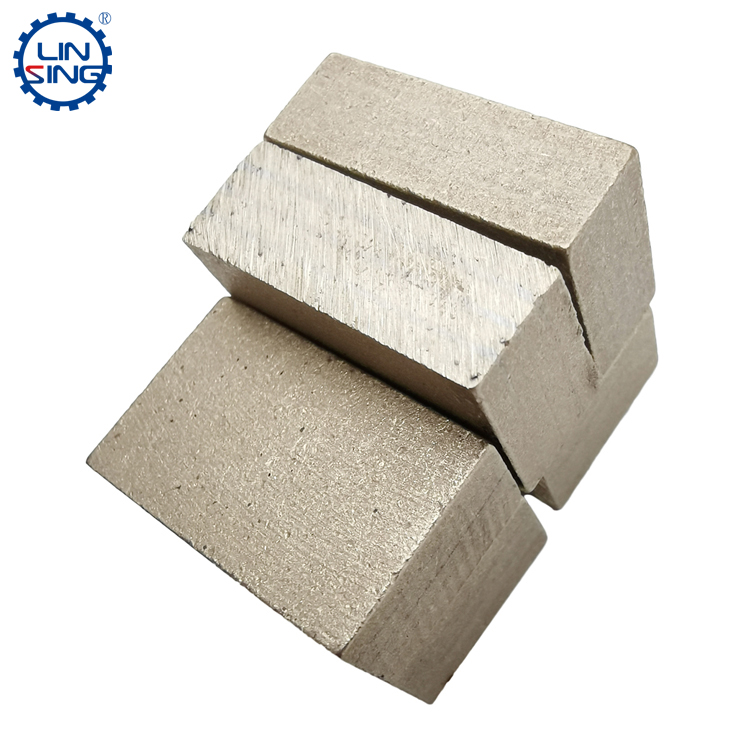

Small-scale diamond segment factories refer to only 10 presses and no more than 10 permanent workers. Even a small diamond segment processing factory opened by husband and wife. These processing plants have been widely established since the 21st century, and they have also promoted the development of the local economy. However, with the development of the diamond tool industry, the living conditions of these small diamond bit factories have become extremely harsh. But it can still survive tenaciously. This article mainly introduces the advantages and disadvantages of these small diamond segment manufacturers.

Let me talk about the advantages of these segment factories:

1. Large manufacturers have also evolved from small manufacturers, In the 1980s, China’s stone processing industry entered a new era. There is a huge gap in the diamond segment. It is these small factories that continuously research the technology of Western diamond segment, and continuously improve the technology and formula, so as to achieve the effect of greatly reducing the cost of diamond segment. Even the current leading enterprises in the industry are slowly expanding from small factories. These factories have a history, a solid foundation, and an extremely rich talent pool. Therefore, small factories are the starting stones of large factories, and they are also a necessary stage.

2: The survival cost of small factories is lower, When exposed to industry risks or external risks, these small factories can easily avoid risks by closing down. For example, during the 2020 epidemic, after a small factory shuts down, workers will hardly be paid, which naturally greatly reduces the cost of survival and is less risky.

3: Small factories are easy to report to the group for heating, Capacity and output are larger than we thought, In Yangyuan Village, Zhuhu Township, Poyang, Jiangxi, Many small private factories have taken root here. When the market demand is large, they can group together and take orders together. A single spark can start a prairie fire and quickly occupy the market. Coupled with the support of extremely low management fees and tax policies, resulting in lower production costs.

Of course, with the development of the times, enterprise scale, standardization, technology, and innovation have become the mainstream development trend, and small diamond bit manufacturers also have unavoidable shortcomings.

4: The competitiveness of small diamond segment factories has declined, Mainly brand competitiveness and product competitiveness. In terms of brands, due to advertising costs and product issues, their living space will continue to be compressed.

5: The labor force is hard to find in small diamond factories, In the early years, production workers were only satisfied with food, clothing and wages. But at present, workers are pursuing comprehensive medical insurance and social security benefits and more humane management, so the living space of these factories is further squeezed.

6: Environmental protection, Now complying with the national policy and responding to the slogan "Green water and green mountains are the golden mountains and silver mountains", the increase of factory environmental protection equipment, environmental protection costs, fines and accountability have caused headaches for the heads of small diamond segments factories.

7: Small diamond segment factories are still facing difficulties in purchasing raw materials. The rapid price increase of materials and other characteristics, in fact, in terms of production costs, due to the increase in raw materials, there is no price competition with major manufacturers.

8: The last point, There is almost no research and development capability in small diamond segment processing plants, and they rely on a few formulas to survive. However, large-scale diamond tool bit manufacturers, such as Linxing diamond segment, invest several million yuan in product research and development every year, and the frequency of updating product performance several or even dozens of times a year makes these small factories look beyond.

In general, the living space of small segment processing plants is reduced, and scale, branding, and technology are the roads that the diamond cutter head industry must take in the future.