The diamond segment will encounter unsharpness during the cutting process. There are two types of unsharpness. The first is that the sharpness of the diamond segment is not enough, but the service life is longer; the second is that the sharpness of the diamond segment is not enough, and the service life is also very short. Below we will introduce the diamond segment according to these two different situations. The sharpness is not enough, but the durability is long:

The sharpness is not enough, but the durability is long:

The specific manifestations of this situation are: the current of the main motor increases, the cutting feed speed is slow, and even the blade jumps and screams sound occur, etc. After appropriately reducing the feed speed or cutting depth, the saw blade will behave normally. But the cutting efficiency becomes slower.

The sharpness is not enough for the following reasons:

1: The diamond segment does not match well with the object to be cut; In other words, if the diamond segment for cutting granite is used to cut marble, this problem will occur, or the diamond segment for cutting hard stone is used to cut soft stone, which will also cause such a problem.

2: The diamond concentration is too high. If the diamond concentration in a diamond segment is too high, during the cutting process, more diamonds participate in the cutting. Under the circumstance, the force area increases and the force remains the same, the pressure decreases, which leads to the deterioration of the cutting sharpness.

3: The amount of fine-grained diamond is too much. Coarse-grained diamond can quickly cut the stone and form a cutting gap. If the amount of fine-grained diamond is too much, the content of coarse-grained diamond will be less, so the cutting gap will be small and the cutting speed will decrease

4: The strength of the diamond is too high. This situation occurs when the strength of the diamond is too high, and the diamond is not easily broken during the process of cutting the stone. In the long-term cutting process, the unbreakable diamond is rounded and sharp case of reduced.

5: The density of the diamond metal bond is too high. The sintering time, pressure, and powder ratio of the metal bond make the bond too hard. When such a metal bond is cut into soft stone, it will be consumed slowly.

6: The width of the diamond segment is too large. The width of the diamond segment is too large. During the cutting process of such a diamond segment, the cutting efficiency will be reduced due to the increase of the force-bearing area.

7: The power supply voltage of the motor is too low. If it is a peak power consumption period, the motor will not be able to cut the stone due to the low voltage.

8: The power of the cutting machine is too small. If the power of the motor is small, the stone may not be cut, just like a small horse-drawn cart.

9: The rigidity of the saw blade base is insufficient, or it is uneven, and there is swing. The saw blade base also determines the cutting performance of the diamond segment to a large extent. Not enough sharpness, not enough durability

Not enough sharpness, not enough durability

The specific performance of this situation is: if the sharpness is not enough, the surface of the diamond segment will not feel rough when touched by hand, and the diamond will fall off with the naked eye, and the service life will be greatly reduced.

There are several reasons for this situation:

1: The metal bond is severely oxidized and loses its ability to hold diamonds. The main reason is that vacuum sintering is not carried out during the sintering process. Using a vacuum sintering machine can solve the problem.

2: The sintering temperature is too low, and the alloying is not completed. The sintering temperature is not up to the standard, which is generally a formula design problem, and may also be an operation problem. But if such problems occur in large quantities, the possibility of multi-mill sintering is high.

3: The hot pressing time is too short, the outer layer of the diamond segment runs out too much material, and the internal alloying effect is also poor. This situation is a problem in the sintering process, and the problem can be solved by increasing the heat preservation and pressure holding time.

4: The mold is too old, the size of the diamond segment is obviously too large, and the density is not enough. The density is a very big obstacle to the durability of the diamond segment.

5: The quality of the diamond is too poor. For example, the post-treatment of the diamond is not cleaned, and the surface contains impurities such as acid. In addition, the diamond strength is too low and the particle size is too large.

Generally speaking, if the diamond segment has the problem of not cutting, it is mostly a problem in the production process of the diamond segment. Of course, problems such as the substrate and the machine are not ruled out. If you encounter such a problem, you can eliminate it according to the above reasons, and finally find the reason to solve the problem.

What should we do if the diamond saw blade is not sharp?

Publish date:2023-01-12 13:51:56 Article From:LINSING diamond tools Clicks:

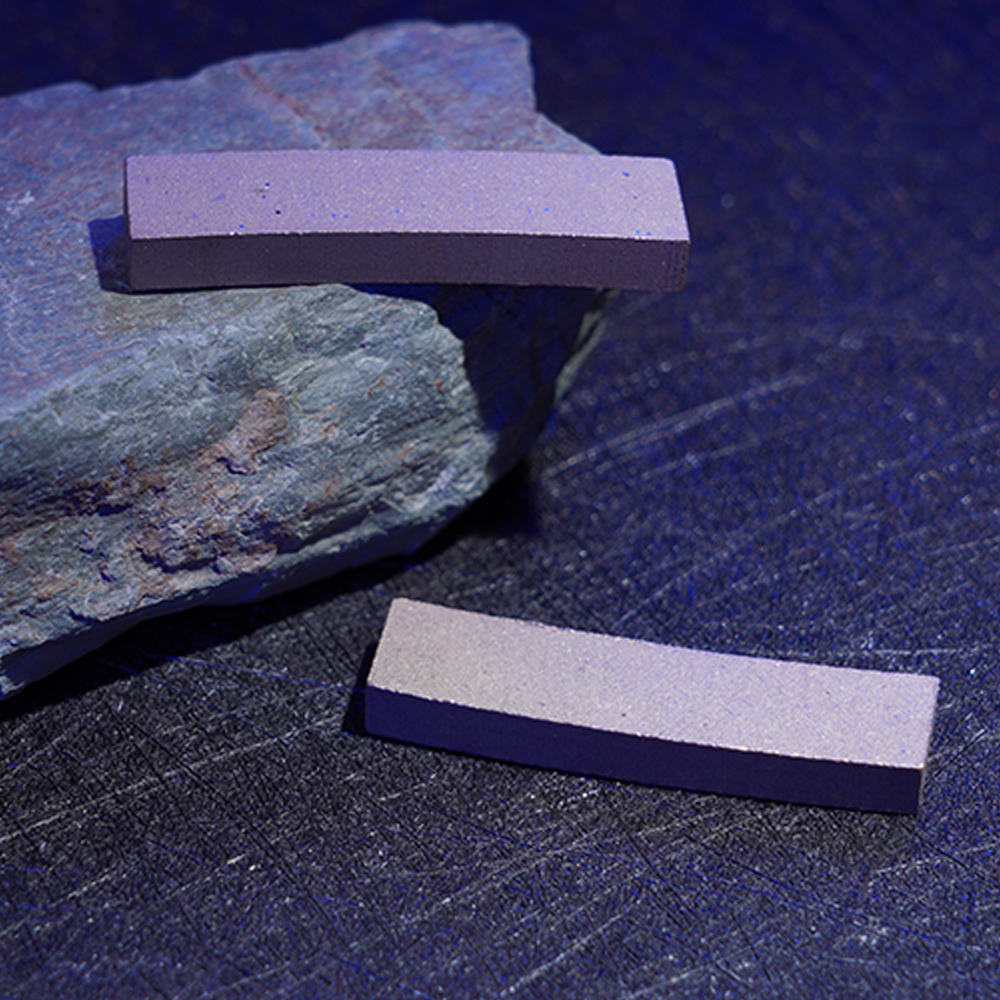

Diamond Segment For Granite Cutting

Diamond Segment For Gang Saw

Diamond Segment For Sandstone Cutting

Diamond Horizontal Blade For Marble

Vacuum Brazed Diamond Saw Blade

Related News

Related Knowledge

- Influence Of Diamond Particle Size On Saw Blade Performance

- Relationship Between Tooth Width Of Diamond Saw Blade And Blank Blade Thickness

- Installation Methods Of Diamond Saw Blade

- Introduction Of Common Parameters Of Diamond Saw Blade

- The Relationship Between Wear Resistance And Efficiency Of Diamond Saw Blades