During the sintering process of diamond segment, different sintering temperature and different pressure will produce different results. Therefore, people who are familiar with diamond tools know that the diamond segment is a relatively unstable product. The unstable factors are mainly caused by some subtle differences in the sintering process. Under normal circumstances, in order to reduce the difference of the diamond segment and improve the stability of the segment, it is a necessary step to improve the diamond segment process.

Before improving the diamond segment process, it is necessary to have an understanding of the diamond segment production process. The diamond segment production process is determined by continuously improving the sintering equipment, sintering temperature, sintering pressure and other parameters of the segment in the production process. It also includes some factors such as mechanical improvements in the production process, processing environment, air temperature and humidity.

Process improvement of diamond segment refers to a method to improve the stability of diamond segment product, which mainly includes the process improvement in the following five aspects. Learn more about it. 1: Improvement of Appearance and Technology of diamond segments

1: Improvement of Appearance and Technology of diamond segments

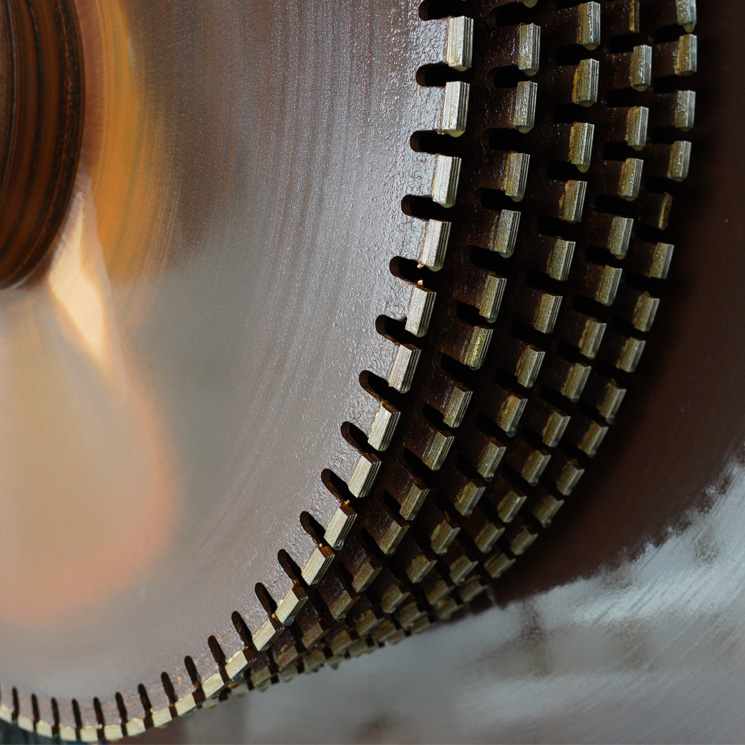

The improvement of this part of the process is mainly whether the segment is sintered evenly during the sintering process, whether there is a flow of material, whether the sintering temperature is reached, whether the sintering pressure is too high, and so on. Process improvements are generally tested for different situations. Among them, the sintering temperature should fluctuate 3-5 degrees Celsius above and below, and five sets of data are taken for comparison, and the most suitable sintering temperature is finally selected according to the actual sintered material strength and grinding performance; In terms of sintering pressure, it has a great influence on the appearance of the segment, and if the pressure is too large, it is easy to form a flow. If the pressure is not enough, there will be obvious gap in the iron sheet and the cutting layer in the segment, which will eventually lead to some problems with the appearance of the product.

The appearance process of the diamond segment is very important. Because in many cases, the production of the segment is completed, and its cutting ability cannot be known. It can only be judged by the appearance. The quality of the appearance can also reflect the advantages and disadvantages of some segments, which has certain reference and applicability.

2: The structure and process of diamond segment are improved.

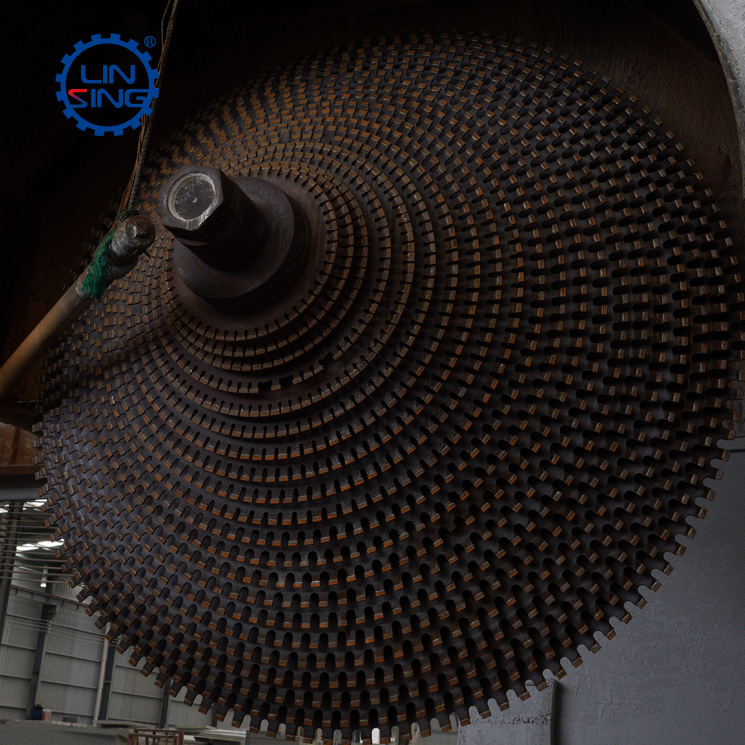

The structure of the diamond segment is very important. Early segments were mostly sandwich structures. However, with the increase in the competitive intensity of diamond segment products, it has been found that changing the structure of the diamond segment can largely improve the cutting state of the segment. In the process of improving the structure and process of the segment, the thickness of the iron sheet in the inter-layer of the diamond segment has great research value. The thicker the thickness of the iron sheet, the cheaper the price of the segment, but the cutting life is weaker. The thin iron sheet greatly increases the price of the segment but performs well in cutting ability. How to choose a blade with a more reasonable thickness must be selected through long-term testing and continuous improvement of the thickness of the iron sheet. The choice of a more reasonable structural process is reflected in the help of the segment.

3: Technological Improvement of Cutting Stability of Diamond Segments

Of course, when it comes to diamond segments, cutting stability is a top priority. The segment will be affected by many factors during the cutting process. For example, during the sintering process of the segment, if single-mode sintering is selected, the temperature of the segment is better controlled. Then, there is little chance that the upper and lower layers of such a segment have poor thermal stability, resulting in quality fluctuations of the segment. However, the disadvantage of single-mode sintering is that the sintering speed is slow, because the sintering process is long, and the production cost increases. Therefore, it is necessary to improve the process, such as two-mold sintering, four-mold sintering, etc. However, in the sintering process of these methods, the temperature control of the segment is more difficult. The temperature of the upper and lower layers may differ by more than ten degrees, and such a sintering environment will cause problems with the quality and stability of the segment. The improvement of the process is only to solve such problems. In general, the principle of diamond segment process improvement is mainly to improve the stability of the segment, make the segment product more stable, and at the same time reduce the difficulty of the process and reduce the production cost. The future automated production is the trend.

In general, the principle of diamond segment process improvement is mainly to improve the stability of the segment, make the segment product more stable, and at the same time reduce the difficulty of the process and reduce the production cost. The future automated production is the trend.

The Principle And Method Of Diamond Segment Process Improvement

Publish date:2022-09-30 13:54:44 Article From:LINSING diamond tools Clicks:

Diamond Segment For Granite Cutting

Diamond Segment For Gang Saw

Diamond Segment For Sandstone Cutting

Diamond Horizontal Blade For Marble

Vacuum Brazed Diamond Saw Blade

Related News

Related Knowledge

- Influence Of Diamond Particle Size On Saw Blade Performance

- Relationship Between Tooth Width Of Diamond Saw Blade And Blank Blade Thickness

- Installation Methods Of Diamond Saw Blade

- Introduction Of Common Parameters Of Diamond Saw Blade

- The Relationship Between Wear Resistance And Efficiency Of Diamond Saw Blades