1. Saw blade deflection

Reason: the debris of the material to be cut is mixed in the cutting seam, causing uneven force on the machine body; The diameter of the flange is too small or the diameters of the flanges on both sides are inconsistent. There is foreign matter between the saw blade and the flange, and it is not installed correctly.

Solution: clean up the debris and enhance the effect of chip removal; Adjust or replace the flange; Install correctly according to the instructions. 2.Quick wear of the diamond segment

2.Quick wear of the diamond segment

Reason: the binder of the segment is too soft (for the material to be cut); cooling water is insufficient; power is insufficient due to loose drive belt or low voltage or improper speed; the saw blade is not perpendicular to the material being cut.

Solution: choose a saw blade with a harder binder according to the material to be cut; Check the cooling water system to ensure the normal operation of the water pump; Ensure the supply voltage; Check the spindle flange to ensure the verticality of the saw blade and the equipment; Check the speed of the saw blade.

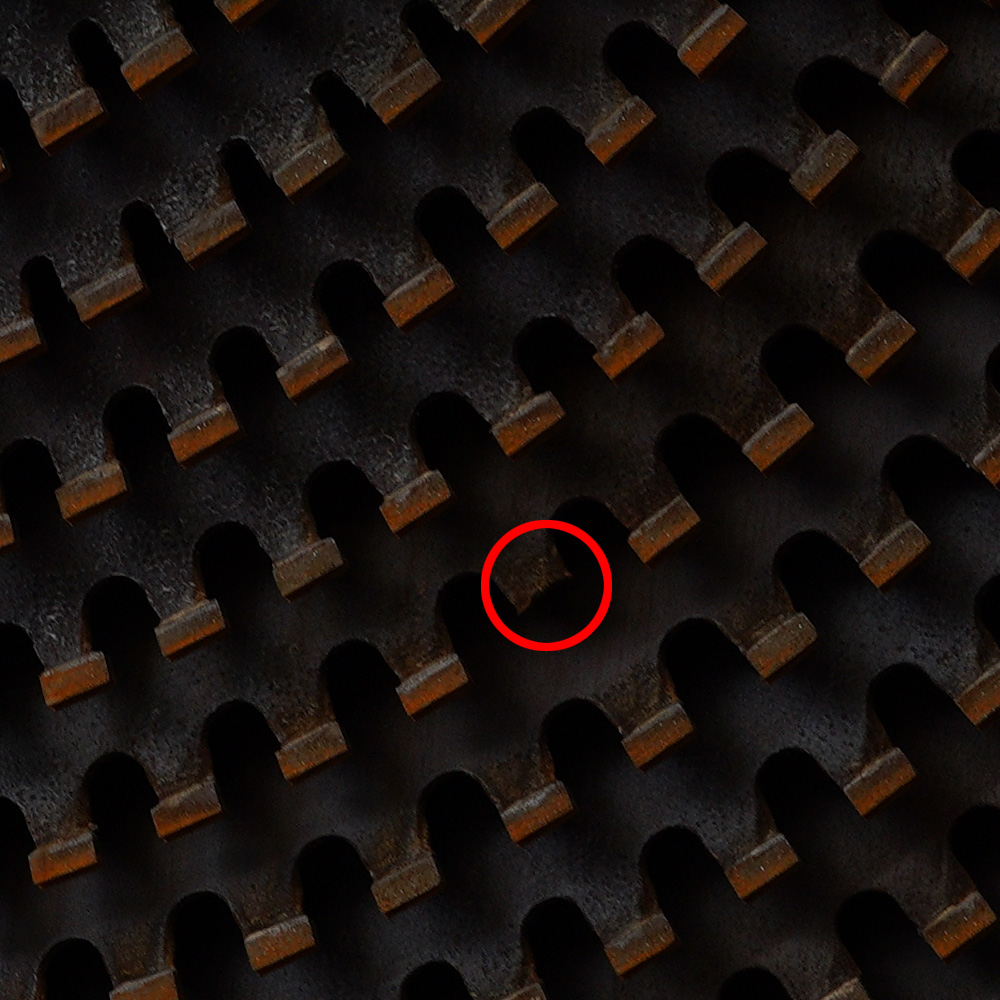

3. The worn joint between the blade blank and the segment .

Reason: the material to be cut is very wear-resistant, and the cutting debris is mixed in the cutting seam and cannot be discharged.

Solution: use protective teeth at special positions of the base body, and use higher pressure cooling water flow to enhance chip removal effect.

4. Uneven wear on both sides of the segment

Reason: the saw blade cuts obliquely, the water volume on both sides is different, and the water volume on one side is insufficient.

Solution: check the tilt of the saw blade; Check the cooling water system.

5. Segment breakage

Cause: the segment bond is too hard; the saw blade is fed too fast.

Solution: select a saw blade with a softer binder according to the material to be cut; Reduce the feed speed of the saw blade.

6. Saw blade out of round

Cause: shaft wear causes a large gap between the center hole of the saw blade and the spindle or incorrect installation.

Solution: replace the worn shaft or repair the center hole.

7. blunt, uncut of the saw blade

Reason: the saw blade bond is too hard; Insufficient power cannot make the saw blade cut normally, the saw blade is not applied with enough cutting pressure; The saw blade line speed is too high.

Solution: choose a saw blade with a softer bond; Check drive belt, voltage and motor; Make sure that sufficient and not excessive cut-in pressure is used; According to the instructions of the equipment, it is better to select the saw blade with the corresponding diameter that matches it.

8. The drop of the segment

Reason: during the cutting process, the material to be cut slides and the segment is twisted off; The segment is hit hard; Worn flange does not hold the saw blade in place, causing the blade to twist; The out-of-round of the saw blade caused by the wear of the main shaft causes the saw blade to be subject to greater impact; The overheated saw blade is subjected to severe impacts. Solution: firmly fix the cut material when cutting; Replace the flanges on both sides; Replace worn spindles; Check the cooling water; Avoid hitting the saw blade when moving the equipment or the material being cut.

Solution: firmly fix the cut material when cutting; Replace the flanges on both sides; Replace worn spindles; Check the cooling water; Avoid hitting the saw blade when moving the equipment or the material being cut.

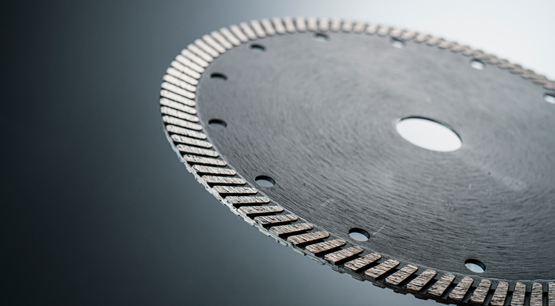

Common problems and solutions in the process of diamond saw blade cutting

Publish date:2023-01-12 15:31:29 Article From:LINSING diamond tools Clicks: