1: Cold-pressed sintered continuous sheet. This type of saw blade is often processed by cold pressing and sintering. The sintered annular blade teeth and the saw blade base are first combined by cold pressing in a bell furnace, and then sintered by hot pressing, and the blade teeth and the saw blade are sintered. The blade base is fixed, and the saw blade saw teeth produced have no gaps at all, and the continuity is very good. During the cutting process, the cutting is completely completed by the grinding force of the diamond, and there is almost no need to rely on the impact force of the saw teeth for auxiliary grinding. Therefore, the cutting efficiency will be slower, and there will often be situations where re-sharpening is required.

Because the cold-pressed sintered continuous piece is sintered by cold pressing, the sintering method cannot guarantee the firmness of the saw blade base and the welding of the cutter head, and the welding strength of the two is not high. Under the influence, there will be various problems with the saw blade, and even the risk of tooth loss, so generally speaking, this kind of saw blade is suitable for a diameter of 105-230mm. If a larger saw blade body is made, there will be larger cutting safety issues, is not recommended.

2: Hot pressing and sintering fish hook pieces. This kind of saw blade is a kind of diamond cutting tool which is made of hot-pressed sintered cutter segment and fixed on the saw blade substrate by high-frequency welding. Such a saw blade is not the same in appearance as the above saw blade. This saw blade has a J-shaped slit on the blade body, and the cutter segment part,In the cutter head part, the cutter segment and the cutter segment are closely connected, which forms a visual feeling that the cutter segment and the saw blade almost seem to be connected together, and the same is true during the cutting process. Without the sawtooth gap, the saw blade has almost little impact during the cutting process, which increases the cutting efficiency and also maximizes the cutting efficiency. The degree of guarantee of the continuity of the saw blade.

In fact, the fish hook blade is a product whose diameter of the cold-pressed sintered continuous sheet transitions in the large direction. This type of saw blade mainly targets the diameter range that the cold-pressed saw blade cannot cover, and mainly focuses on the saw blade with a diameter of 250-450mm. Due to the high frequency welding, the cutting process often needs to carry water.

3: Vacuum brazing continuous sheet. This type of saw blade adopts the vacuum brazing process, and the diamond is plated on the surface of the saw blade by brazing. The size of this type of saw blade can cover the diameter range of 105-350mm. During the cutting process, the saw blade is extremely sharp. In addition, the continuity is very good, so this product makes up for the lack of sharpness of the cold-pressed sintered saw blade, and also takes into account the blank market where the hot-pressed sintered blade cannot be dry cut. This type of saw blade is currently being vigorously promoted due to its versatility and low requirements for cutting machinery, and will become the mainstream of the market in the future.

4: Electroplating continuous cutting pieces. The electroplating sheet has a similar process to the above brazed saw blade, but electroplating is gradually in the process of being eliminated due to the problem of pollution and the problem of material consumption and holding force of the electroplating sheet. However, this type of saw blade also has its own advantages. For example, it can be made into an ultra-thin saw blade for cutting jade, agate, glass and other materials.

5: Vacuum brazing cutting and grinding wheels. This type of saw blade is rarely used. In simple terms, this type of saw blade can be cut and polished. But the disadvantages are equally obvious, that is, the cutting is not good (mainly the thickness is too thick), and the grinding is not good (mainly the thickness of the sheet body is not too thick during the grinding process, which is prone to deflection). Therefore, it is still in the process of improvement, so I won't go into details here.

In general, the toothless continuous film is characterized by good cutting stability, and there will be no edge collapse during the cutting process. It means cutting hard materials, as long as you increase the strength of the matrix and improve the diamond grade, but cutting soft materials, stable cutting, and no edge chipping are the most concerned issues in the stone industry, especially at present there are some new Products, such as natural soft marble, artificial granite, artificial microcrystalline stone, jade, ceramic tile, porcelain and other materials, many have such characteristics, so in the process of cutting, it is particularly necessary to ensure the cutting quality, and maintain continuity without Tooth saw blades are a good option.

Types And Uses Of Toothless Saw Blades

Publish date:2022-07-19 11:49:38 Article From:Linxing Diamond Tools Clicks:

Vacuum Brazed Diamond Saw Blade

Continuous Rim Diamond Cutting Disc

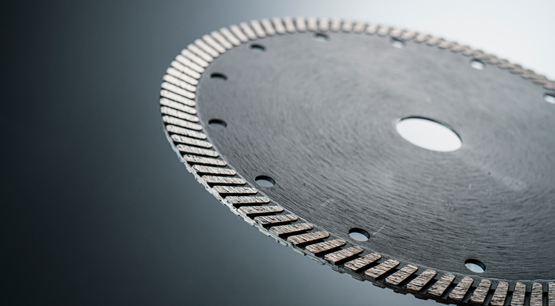

Turbo Cutting Disc

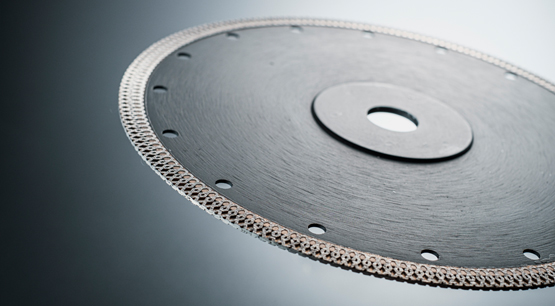

X Mesh Turbo Cutting Disc

Turbo Type Protection Teeth Cutting Disc

Related News

- Commonly used segment styles for granite 300-1000mm saw blades

- How to choose diamond circular saw blade and diamond segments?

- Introduction of ceramic saw blades and diamond segments used

- The difference between saw blade diamond segment and other diamond segment

- How to solder the diamond segment on the saw blade?

Related Knowledge

Brazed diamond cutting blade is a very special diamond tool This saw blade uses vacuum brazing to fix the diamond on the saw blade substrate The entire saw blade has a simple structure and less sintering and welding processes, the stability is higher This article mainly introduces the advantages and disadvantages of brazed diamond cutting discs

07/04

2022

Why Are Super Large Diameter Diamond Saw Blades Not Used For Block Cutting?

Diamond saw blades have great application differences according to the change in size For example, the size of the saw blade for cutting blocks is mainly concentrated in 900-3500mm Why aren t super large diameter saw blades used for block cutting? What s the difficulty? Can it be solved? These are the questions to be discussed in this article

07/04

2022