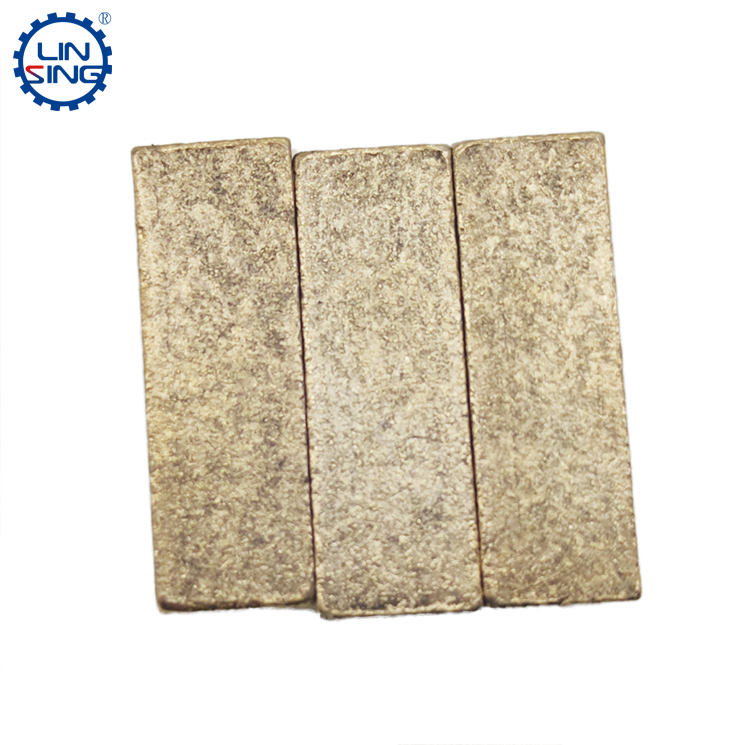

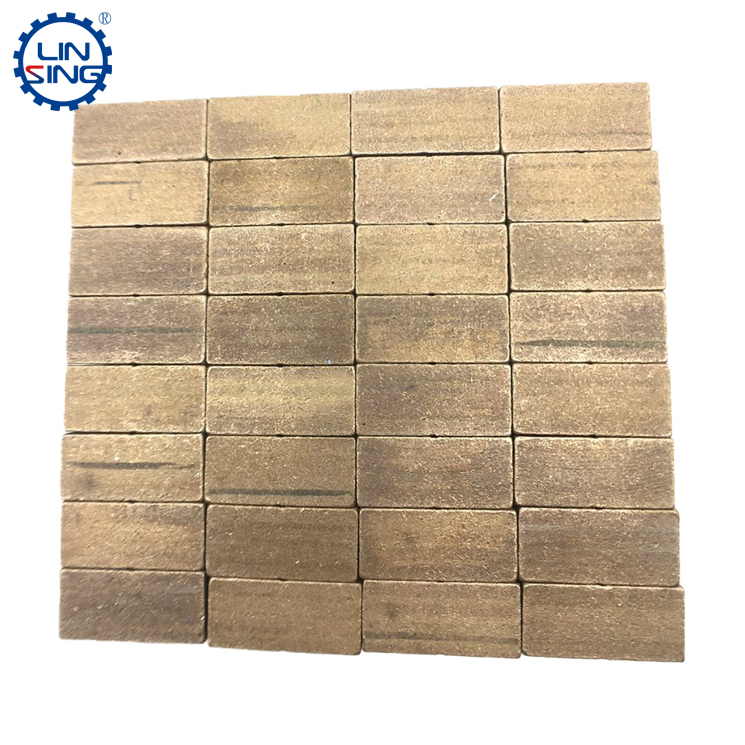

The diamond segment is combined by the matrix bond and the diamond by sintering, and the matrix bond is mainly composed of various metal elements. Among them, a certain metal with the best content, which we called the base material of the segment. Among them, the most common one is the iron-based segment. As the name suggests, the segment has the highest content of iron in the matrix bond; according to this way of calling, the segment with the highest copper content is called copper-based segment; the segment with the highest cobalt powder content is called cobalt-based segment; and the segment with the highest tungsten carbide content is called tungsten carbide-based segment.

The segments made of these four common substrates are also quite different. Among them, tungsten carbide (chemical name WC), which is a metal compound with high hardness, has a Mohs hardness of about 9. In nature, it is only lower than diamond and a few compounds mainly play the role of skeleton in the segment, that is, the amount of diamond can be appropriately reduced, and tungsten carbide is used to support the cutting work of the segment. However, this material has some disadvantages: for example, the material is brittle, although titanium, cobalt and other elements can be added to improve the situation, but the latter two metal materials are expensive, and the framework material often cannot produce a good solid phase with other metals with sintering, not to mention the need for higher temperature liquid phase sintering, so the overall segment mainly uses cobalt powder and titanium powder as the core metal sintering materials. Although the content of WC in this type of segment is relatively large, most people still say that it is a segment for other types of substrates.

So among the three most common segments, cobalt-based segment, iron-based segment, and copper-based segment, which one is the best? In fact, it does not make any sense to simply compare data with price and demand. We can compare from several aspects such as availability, price, and performance.

In terms of usability, cobalt-based segments are currently mainly used for marble cutting. Due to the better holding force and stability of the matrix bond of cobalt-based segments, if the grade of diamond held is high enough, the segment will have a higher cutting efficiency and higher life, the most commonly used segments include gang saw segment, sand saw segment, Italian combination saw blades, etc. The copper-based segment is often used for the cutting of marble that is not very abrasive, as well as the cutting of softer limestone, travertine, travertine and other stones due to the softer carcass. At present, iron-based segments are mostly used for the cutting of very abrasive sandstone, medium-hard granite, volcanic rock, quartz stone and other stones.

In terms of price: the price of the segment is related to the price of the powder material itself. Cobalt powder is the most expensive, copper powder is the second, and iron powder is the lowest. Naturally, the price is also arranged in this order. The price of the segment is second, and the price of the iron-based segment is the cheapest.

In terms of performance: the cobalt-based segment has the best diamond holding force and the best stability. The carcass of the copper-based segment is soft and the grinding degree is not high. It is suitable for cutting stones with low grinding degree. Otherwise, the service life of the copper-based carcass will be shortened due to the rapid consumption of the copper-based carcass. The iron-based segment has a very good holding force, high hardness and good abrasiveness, but the segment is easy to oxidize, and if the grinding is too high, the diamond consumption of the segment will be greater than the consumption of the carcass, which will lead to the saw blade can’t cut the stone.