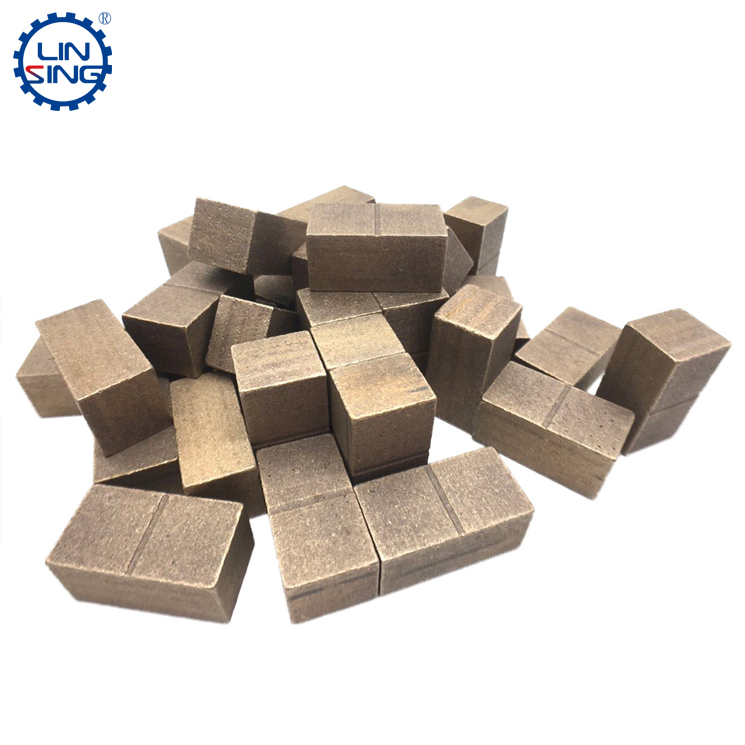

Diamond segments are generally not used alone. Almost all segments need to be welded on the substrate, such as welded on the substrate of the circular saw blade, or the substrate of the abrasive tool, or the substrate of the drill bit. The only difference is the welding method. Some substrates are welded by flame, and some substrates are welded by laser. However, most of the segments are welded by high-frequency welding.

The process of high-frequency welding of the segment is a new welding process in which the steel matrix (high manganese steel or alloy steel) of the saw blade and the segment are connected by the skin effect and the adjacent effect produced by the high-frequency current. The emergence and maturity of high-frequency welding technology is a key process in the production of straight seam welded pipes (ERW), which can quickly heat the segment without overheating itself. The quality of high-frequency welding directly affects the strength, quality level.

Knowing the principle of welding the segment on the substrate, then we need to know the three elements that need to be paid attention to in the process of welding the segment:

Frequency: The frequency of high-frequency welding has a great influence on the welding of the segment. Generally speaking, the higher the frequency, the deeper the high-frequency current can penetrate the solder or the segment matrix, and the larger the heating area. The larger the heated area, the direct impact on the uniformity of solder melting. However, not all materials have skin effects suitable for high power, such as aluminum, cadmium and other metals, so when welding the segment, you can choose a low-frequency high-frequency welding equipment such as 30-100KHZ to preserve the properties of the material itself. Such frequencies can achieve the best current distribution. At present, solid-state high-frequency technology has appeared on the high-frequency welding machine of the segment. This technology will automatically sense the thickness of the segment and automatically adjust the frequency. If there is such a machine, it is easy to adjust the frequency of high-frequency welding.

Motor power: The frequency can be automatically adapted, but the motor power directly determines the current size. If the control frequency is to make the segment and the solder heat more evenly, then the motor power directly affects the heating speed. The higher the motor power, the faster the segment heats up. Therefore, if you are welding the segment frequently, try to increase the motor power as much as possible. If it is a stone factory, the requirement of the welding speed is not high, then you can choose a 15KW or 25KW welding machine.

1·Welding time: During the welding process, time control is very important. If the welding time is too long, the stability of the segment will be reduced, and the segment may even undergo structural changes. If the welding time is too short, the solder may not be completely melted, resulting in a decrease in the welding strength. So how do you choose the welding time? Welcome to see our next wonderful sharing.

High Frequency Welding Time Control of Diamond Segment

Publish date:2022-07-14 16:43:31 Article From:Linsing Diamond Tools Clicks: