In the process of cutting the diamond segment, especially the newly welded segment, a problem is often encountered. The stone cannot be cut. The specific manifestation is that the saw blade and the stone make a sharp and unnatural sound during the cutting process. The diamond on the surface of the segment is not The edge is out, and the segment temperature rises very fast, the depth of the stone cutting is very small, etc. In such a situation, it can basically be determined that the diamond segment is difficult to edge.

Why is the diamond segment difficult to sharpen?

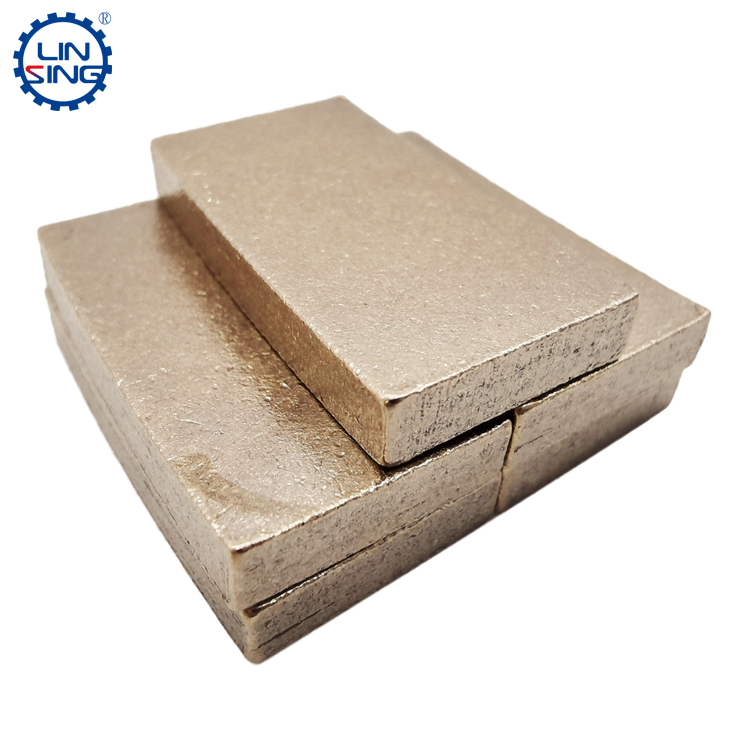

The diamond segment is a product of the combination of diamond and metal matrix through sintering. During the cutting process, as the matrix is consumed, the diamond is continuously tapped to finish the grinding of the stone, but when the consumption rate of the matrix is When it is very low, especially when cutting the stone with poor abrasiveness, the diamond can only work with a fast blade. If the diamond segment is welded, the blade has been in a slow blade state during the process of cutting the stone. It will affect the processing efficiency. Secondly, it will also cause huge damage to the machine. Finally, this kind of cutting method also increases the production costs such as electricity and water costs. Therefore, rapid cutting is a problem that must be solved in stone cutting.

So what kind of diamond needs to be edged?

Generally speaking, the segment used to cut granite does not need to be edged, because granite has high abrasiveness. During the process of cutting granite, the surface of the carcass will be quickly consumed, so during the operation, we just started When cutting, you must lower the speed and the depth of the knife so that the segment starts to come out of the edge, and then you can cut normally. Marble segments need to be sharpened, because most of the marbles are relatively soft, especially some soft marbles. If you don't sharpen the edge, the segment will be in the process of sharpening the first few days.

So how does the segment become the edge?

There are currently three ways to sharpen the marble segment. The first is to use materials with high cutting abrasiveness to assist the sharpening. If the marble segment has been welded to the surface of the saw blade, and then the problem of sharpening is found, you need to find some materials with higher abrasiveness. Perform auxiliary edge sharpening, such as refractory bricks commonly used. Cutting such materials can help the segment to sharpen the edge quickly. The second type is grinding wheel sharpening. This is a service provided by diamond segment manufacturers to help customers. It is mainly used to sharpen the segment with a fast-rotating grinding wheel. The disadvantage of this approach is that the sharpening is uneven. And due to the problem of the depth of the blade, the diamond was wasted. The third type is the automatic cutting edge machine, which can quickly liberate manpower and realize automatic segment cutting. Linxing Diamond Tools provides free services to help customers sharpen the edge to solve the problem that customers are difficult to sharpen the edge due to cutting marble.

What should I do if the diamond segment is difficult to edge?

Publish date:2022-07-08 14:48:20 Article From:Linsing Diamond Tools Clicks:

Diamond Segment For Granite Cutting

Diamond Segment For Gang Saw

Diamond Segment For Sandstone Cutting

Diamond Saw Blade For Marble

Diamond Horizontal Blade For Marble

Related News

- Several aspects to consider in diamond segment customization

- Diamond segment on diamond requirements

- Liquid phase sintering and solid phase sintering of diamond segment

- 70% diamond segment factory planning adjust price due to diamond powder price is increasing

- HOW TO CHOOSE THE BEST SUITABLE DIAMOND SEGMENTS

Related Knowledge

- The Difference Between Dry And Wet Diamond Saw Blade

- How To distinguish Diamond Saw Blades From Appearance

- What Should We Do If The Diamond Saw Blade Is Lost Sharpness?

- Influence Of Diamond Particle Size On Saw Blade Performance

- Relationship Between Tooth Width Of Diamond Saw Blade And Blank Blade Thickness