Most of the diamond segment heights are fixed. For example, the common diamond segment heights for cutting granite are mostly 12mm, 13mm, 15mm, 20mm and 30mm, while the heights for cutting marble are mostly 8mm, 10mm, 12mm, etc. But common diamond segments will have some errors, and the error range is about 0.1mm. This kind of unevenness of the diamond segment is a relatively normal situation, mainly due to the following reasons:

1. The diamond content is different. The diamond concentration of each diamond segment is slightly different. Under the same volume and weight, the diamond will not decrease in volume during the sintering process, while other metal powders will decrease. In this case, the volume of the diamond segment with high diamond concentration will be slightly larger, and the volume of the diamond bit with lower diamond concentration will be slightly smaller.

2. The difference of each sintering machine will also lead to the difference of the diamond segment. For example, a certain diamond segment is sintered at a sintering temperature of 803 degrees Celsius. But due to mechanical differences or many reasons for the impact of mechanical aging performance, the problem of some diamond segment sintering machines can only reach 799 degrees Celsius. Apart from temperature, different sintering machines also have different performances in terms of pressure. These two factors directly affect the height of the diamond segment and there will be differences.

3. There are some other reasons, such as the number of sintered modules at one time. In order to improve the sintering efficiency, some manufacturers sinter 4 molds at the same time in one machine, which will cause the temperature of the upper, middle and lower modules to be completely unreachable. Due to the sintering situation change, so most of the diamond segment will appear uneven.

In fact, the above is about the uneven height of the diamond segment in some relatively normal processing links. There are also some cases that will cause serious unevenness of the diamond segment, mainly caused by the following situations:

1. The sintering temperature causes a big difference in the diamond segment, such as power failure, improper operation during the sintering process, improper placeof module, problems of seting temperature, the failure of sintering machine etc. These reasons will lead to obvious unevenness of the diamond segment.

2. Unevenly mixed powders lead to large differences of the diamond segment, such as uneven mixing of diamond and powder. Under the same sintering environment, due to material differences, the diamond segment will naturally have a larger height difference.

3.There is a problem with the pressure. If the pressure is too small, the height of the diamond segment will be inconsistent. Especially when the pressure holding pressure is not enough during the sintering process, or the pressure will be decompressed before the diamond segment has cooled down.

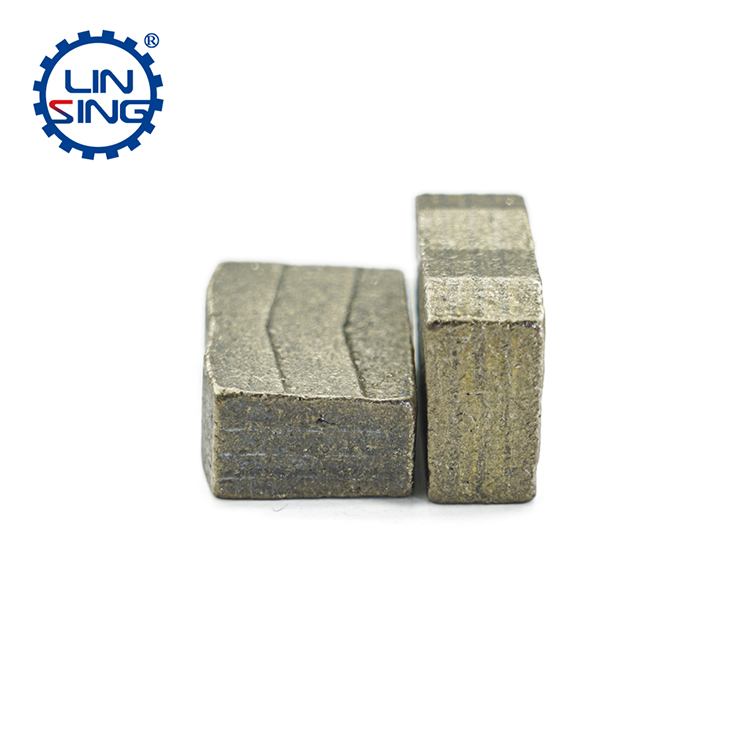

4. The selection of the non-working layer is wrong during the mold loading process. If the iron sheet is selected incorrectly, the height of the diamond segment will also have a large difference. This difference may even differ by 1-2mm, resulting in the appearance of such a diamond segment, which seems like two products. In fact, there is a huge difference in performance.

So what is the impact of the uneven diamond segment? How to solve this problem? Most of the uneven diamond segment have poor stability. During the cutting process, segments are lost and broken often occur. And the cutting performance is often not high during the cutting process, such as low cutting efficiency and short service life of the diamond segment. and so on. As for the solution, the height difference and size difference of the diamond segment are often an important basis for judging the quality of the diamond segment. It is the best way to avoid risks by choosing a product with a relatively stable diamond segment height as much as possible. If you have purchased such a diamond segment, it is recommended to intersperse it with a high-quality high-quality diamond segment for welding. Do not use this type of diamond segment for all of the whole circular saw blades, whose risk is too great.