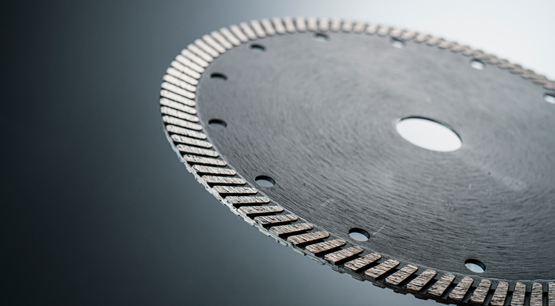

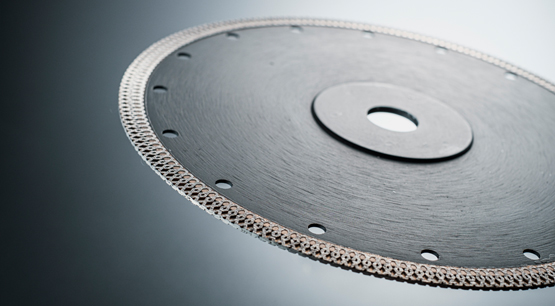

The processing accuracy of the diamond segment actually affects the range of the left and right ends of the saw blade during cutting. The purpose of improving the processing accuracy is to reduce the cutting error as much as possible, and finally make the diamond segments have accurate cutting performance, uniform cutting seam and accurate cutting results during the cutting process.

There are many ways to improve the precision of diamond saw blades, such as increasing the thickness of the substrate, enhancing the rigidity and toughness of the substrate, reducing the physical stress during the cutting process of the substrate and reducing the amplitude of end jumps and radial jumps. There are also some properties of the diamond segment that can be changed. The change of these properties can quickly help the diamond segment to improve the cutting accuracy. Below we can learn more about:

1. Increasing the density of the segment can significantly increase the cutting accuracy of the segment.

During the cutting process of the segment, the higher the density of the segment, the higher the packing density of metal atoms per unit volume. The difference in weight of the same volume of the diamond segment can significantly improve the amplitude of the deflection of the diamond segment during the cutting process, and at the same time improve the cutting accuracy of the diamond segment.The modification of the diamond segment density requires more consideration, such as the ratio of metal powder, the ratio of diamond powder and matrix, the concentration and grade of diamond powder, which can directly affect the diamond segment density. Exactly, these problems can be solved. Enhancing the categories of solid-phase sintered metal compounds, adding more easily impregnated metals, and metals that are more wettable with iron and copper are good ways to solve that problem. This approach will lead to the use of some expensive metal powders and increase the manufacturing cost, but the stability can be improved.

2. Increasing the sharpness of the segment can significantly improve the cutting accuracy of the segment.

During the cutting process of the segment, if the hardness of the diamond used by the segment matches the hardness of the stone, the diamond can be continuously broken and edged during the cutting process. In addition, the stone can also be cut quickly. Under such a good cutting condition, the cutting precision of the segment can be improved. The fast cutting segment has a stable cutting pattern during the cutting process, the saw blade cuts smoothly and there is no problem of saw blade jamming and segment displacement caused by jamming, so the cutting accuracy can also be greatly improved. Actually, there are many ways to improve the sharpness of the segment, such as increasing the number of interlayers of the segment, shortening the length of the segment, increasing the sawtooth spacing, appropriately reducing the thickness of the segment, increasing the diamond and improving the diamond grade.

3. The stability of the size of the segment itself can also significantly improve the cutting accuracy of the segment.

There is an error in the size of the diamond segment. These errors are due to the large oxidation of the graphite mold during the long-term sintering process.Or in the process of demolding, due to the improper use of tools, the graphite mold has scratches, and the long-term accumulation of scratches will increase the width or length of the diamond segment. In the production process of the diamond segments, the size of the diamond segments are different due to the use of different molds for production. When the size of the segment is inconsistent and used to cut stone, the cutting gap will naturally be too narrow or too wide. The problem of cutting gap error caused by such different sizes can only be solved by reducing the number of times the graphite mold is used. But this will greatly increase the manufacturing cost of the segment, so the segment with high precision requirements is often more expensive.

4. The sintering process leads to problems with the cutting accuracy of the segment.

This problem is mainly reflected in the sintering process of the diamond segment, the temperature of the segment is too high or too low, and the flow or incomplete sintering occurs, which will directly lead to major quality problems in the cutting performance of the segment. Even many segments may not be able to cut the stone during the cutting process, so it is even more impossible to guarantee the accuracy.

The reason why the diamond circular saw cutting stone will lead to insufficient precision is often not the reason of the segment. There are many other reasons, such as machines, such as improper operation, etc. But if you want to cut stone with higher precision, the diamond segment is the point that must be paid attention to.