The ceramic saw blade is a diamond cutting tool that welds the diamond segments on the base of the diamond saw blade by high-frequency welding. Since ceramics are products with low hardness and high brittleness, extreme care should be taken during cutting. The requirements for saw blades are also higher, especially during the welding process, which requires more attention. First of all, in the early stage of welding ceramic cutting saw blades, we need to select suitable diamond segment products, which generally meets the following characteristics:

First of all, in the early stage of welding ceramic cutting saw blades, we need to select suitable diamond segment products, which generally meets the following characteristics:

Excellent material: ceramic cutting saw blades usually use diamond with high hardness, high density and high wear resistance as the blade material, which can effectively improve cutting efficiency and cutting quality.

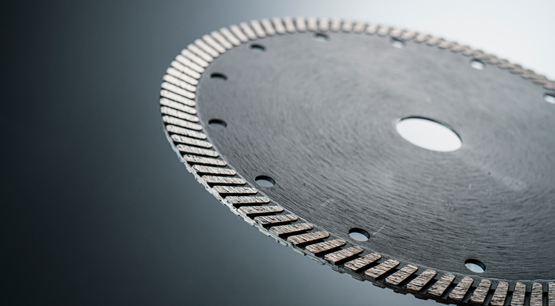

segment sharp: The segment of the ceramic cutting saw blade usually adopts a flat or convex blade (reinforced type), because this blade shape can improve the stability and precision of cutting, and reduce the noise and particles generated by cutting.

Segment size: ceramic cutting saw blades are generally smaller in size, because ceramic cutting does not require a large cutting area, and a small size of the segment can improve the accuracy and efficiency of cutting. (Usually less than 450mm in diameter)

Segment shape: Scalloped segments are often used for ceramic cutting saw blades, as this shape better fits the ceramic cutting needs while reducing vibration and noise during cutting.

The segment of the ceramic saw blade is usually connected to the saw blade blank by welding. Specifically, a high-temperature welding method is usually used to fix the diamond blade on the metal substrate of the saw blade to form an integral blade. Welding methods include laser welding, high-frequency induction welding, flame welding and other methods, among which high-frequency welding is the most commonly used method.

During the welding process, the diamond segment and the metal substrate need to be heated to a certain temperature, and then the two are joined together at high temperature. This process requires strict control of temperature and time to ensure the quality of the weld and the durability of the blade. After welding, the segment needs to be grind and balanced to ensure the cutting effect and safety.

The welding of ceramic saw blades is an important process, and the following points need to be paid attention to:

Choose the right welding equipment and tools. Generally speaking, the welding of ceramic saw blades requires the use of high-frequency welding machines and professional welding tools, such as welding fixtures, electrode heads, etc.

Control the welding temperature and time. Welding temperature and time are important factors affecting welding quality. Excessively high temperature and time will cause problems such as deformation and cracking of the welded parts, and excessively low temperature and time will affect the welding strength and quality.

Choose the appropriate welding material. The segment of the ceramic saw blade is generally welded by brazing, so choosing the right brazing material is very important for the welding quality.

Make sure the welded area is clean and dry. The cleaning and drying of welding parts is also very important for welding quality and effect, and can be treated with cleaning agents and dryers.

Run a quality check. After the welding is completed, quality inspection is required to ensure that there are no cracks, air bubbles, looseness and other problems in the welding part to ensure the quality and stability of the welding.

Laser welding is also a common way of cutting ceramics, the following is the process of laser welding ceramic cutting:

Cutting segment pretreatment: First, the surface of the cutting segment needs to be cleaned and treated to remove surface dirt and oxides and ensure the quality of laser welding.

Configure laser welding equipment: configure laser welding equipment in a suitable position, adjust welding parameters and beam position, etc., to ensure the accuracy and consistency of welding.

Focused beam: Laser welding uses a high-energy-density laser beam for welding, and the laser beam needs to be focused on the welding point of the cutting segment to ensure welding quality.

Melting cutting segment: By controlling the energy and beam position of the laser welding equipment, the cutting segment is melted and fused with the base material to form a complete weld.

Cooling and cleaning: After the welding is completed, the weld seam needs to be cooled and cleaned to remove welding residues and ensure welding quality. . It should be noted that laser welding requires professional equipment and technology, and operators need to receive professional training and master relevant safety knowledge and operating procedures.

It should be noted that laser welding requires professional equipment and technology, and operators need to receive professional training and master relevant safety knowledge and operating procedures.

In general, whether it is laser welding or commonly used high-frequency welding, carefulness and professionalism are important factors for product stability.

Welding diamond segment for ceramic saw blades

Publish date:2023-03-29 09:27:49 Article From:Linsing diamond tools Clicks: