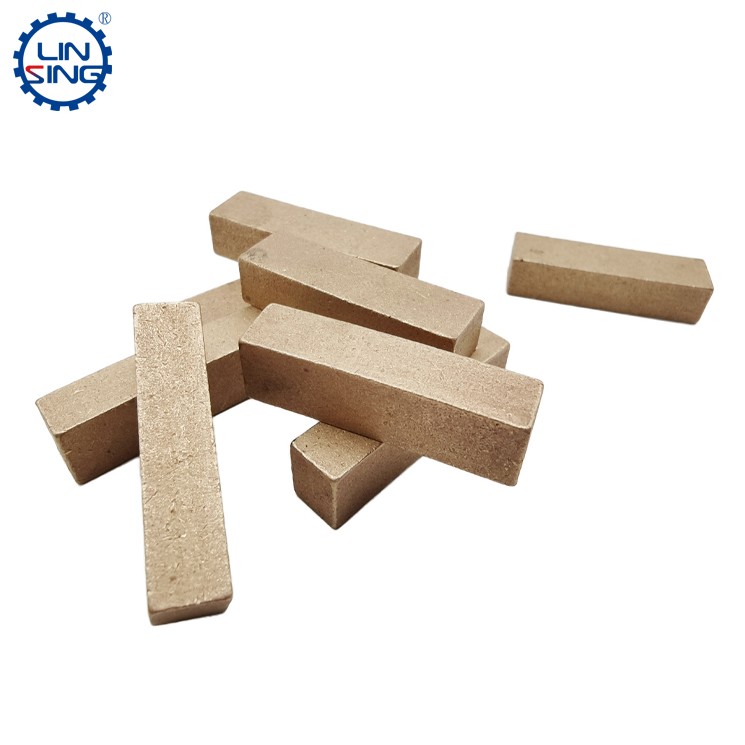

In the process of continuous use, the diamond segment will gradually become old. In order to better protect the saw blade substrate, the diamond segment will not be used until the end. When there is 3-5 mm remaining, the segment must be replaced. However, during the cutting process of many saw blades, due to the substrate or segment, the saw blade is bent, or the main shaft of the machine has problems, resulting in problems with the saw blade and segment, such as segment eccentric wear and segment grinding. However, if such a segment cannot be repaired, it needs to be recycled.

The recycling price of these scrapped segments?

Waste segments are often calculated in kilograms, and the price is very low. From the perspective of cost, the recycling price of waste segments per kilogram is only 13-20 RMB. Although it is such a small amount of money, it can save a little cost. Although most stone factories don't care, but for the welding workshop, the number of waste segments every day is very considerable, which causes these segment welding factories to become The source of waste segment recycling.

What are these used segments for recycling?

Although the recycling price of waste segments is very low, on average, each kilogram of diamond segment contains 200 carats of diamond powder, and other metal components are also very rich. If the iron, copper, cobalt, nickel, and manganese in the segment can be recovered , Zinc, tin and other raw materials are extracted, so the entire process of recycling segments is a profitable business.

How to refine scrapped segments?

The diamond in the diamond segment is very valuable for recycling, so we choose industrial hydrochloric acid for soaking to wash out the diamond in the segment. After pickling, almost all the metal is melted with hydrochloric acid, and the remaining solids are silicon carbide and diamond. After filtering the solid material, diamond and silicon carbide can be obtained separately at this time. The diamond is passed through the particle size sieve to distinguish the grades, and then the diamond segment can be continued to be produced. As for tungsten carbide, after grinding, you can continue to return to production, while other metals in the solution, select the more expensive metals to be hydrolyzed, vulcanized, and calcined to form new powders, which can also be used to continue the production of diamond segments.

Can the recycled diamond still be used?

The recycling price of waste diamonds is very cheap. In Shuitou, Fujian, a large amount of diamonds are recycled twice and three times. During the sintering process, the diamond will be partially carbonized. After multiple sintering, the diamond powder becomes very unstable, especially The structure of some diamonds has changed and become very brittle. In the process of cutting the stone, there are often situations such as inability to cut and poor stability. Of course, for manufacturers with low requirements for processed products, this kind of segment will be used on a large scale because of its cheapness. However, stone factories with high technical requirements and high cutting stability requirements will hardly choose such a segment.

Jiangxi Linxing Diamond Tools Co., Ltd. promises that it will never produce a segment made of recycled diamonds and make better diamond segment products.

The purpose and value of recycling of used diamond segments

Publish date:2022-07-08 11:57:09 Article From:Linsing Diamond Tools Clicks:

Diamond Segment For Granite Cutting

Diamond Segment For Gang Saw

Diamond Segment For Sandstone Cutting

Diamond Horizontal Blade For Marble

Vacuum Brazed Diamond Saw Blade

Related News

- Several aspects to consider in diamond segment customization

- Diamond segment on diamond requirements

- Liquid phase sintering and solid phase sintering of diamond segment

- 70% diamond segment factory planning adjust price due to diamond powder price is increasing

- HOW TO CHOOSE THE BEST SUITABLE DIAMOND SEGMENTS

Related Knowledge

- Influence Of Diamond Particle Size On Saw Blade Performance

- Relationship Between Tooth Width Of Diamond Saw Blade And Blank Blade Thickness

- Installation Methods Of Diamond Saw Blade

- Introduction Of Common Parameters Of Diamond Saw Blade

- The Relationship Between Wear Resistance And Efficiency Of Diamond Saw Blades