People often see two kinds of diamond segments in the market, it is a segment for cutting stone, mainly including quarry segment, large segment, medium diameter saw blade segment and some small saw blade segments. There is also a segment for cutting concrete, ranging in size from 105-1200mm, Mainly used for cutting steel-concrete materials with steel bars inside. There are many differences between them, and we will introduce them in detail below.

1: The size range is different, The size of the segment required for the stone saw blade is very large, from the mine saw blade with a diameter of 4600mm, to the smallest slice for cutting stone with a diameter of 105mm, Most of the saw blades for cutting concrete are relatively small in size, and there are almost no saw blades with a diameter of more than 1600mm.

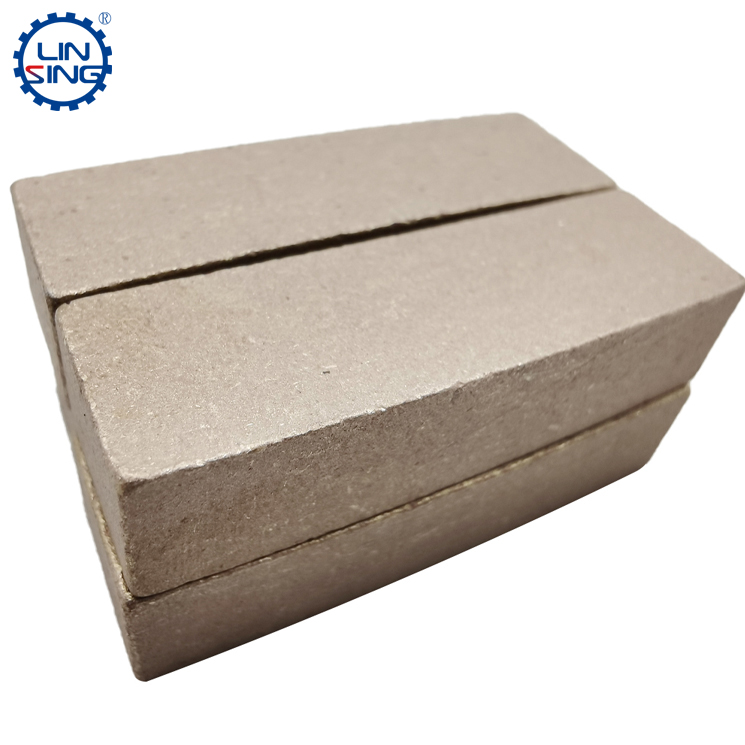

2: The shape of the segment is different, The shape of the segment is different, and the shape of the stone cutting saw blade is affected by the cutting quality of the stone, that is to say, whether there are edge chipping, cracks, cutting offset and other problems during the cutting process, so in the design of the segment, more M, V, R, or arc, etc. However, for the cutting of concrete, whether it can be cut or not and the life of the cutting are more important parameters, and there is almost no requirement for the cutting quality. Therefore, in the production process of the concrete cutting segment, there are many sawtooth shapes, and there are also some Most manufacturers will use turbine-shaped cutter heads to improve cutting capacity.

3: Different welding methods, Due to the continuous cutting in the process of stone cutting, it is necessary to control the generation of heat, especially high-frequency welding is afraid of high temperature.

If you continue to cut, the temperature will continue to increase, the diamond segment will become softened, resulting in cutting quality problems.

But for the segment of concrete cutting, you can rest for a while during the cutting process, especially when the cutting surface is not too large, the process of replacing the cutting surface can alleviate this situation very well, and many construction sites do not have water, so when people weld concrete saw blades, most of them use laser welding, which allows the blade to withstand higher temperatures without falling off.

4: The diamond ratio is not the same, Since stone is a very expensive decorative material, Especially in recent years, people have attached great importance to stone resources, and under the compulsory control of mining capacity, stone prices have become increasingly high. The higher the price, the higher the cutting precision, so using a finer particle size to cut the stone will have a good cutting effect. Most of the segments for cutting the stone use diamond particles with a particle size of 50-60#.

Cutting reinforced concrete is not the same. The hardness of the steel bar in the steel mix is completely different from that of the concrete, so the required particle size is relatively rich, the coarse particle size is required to quickly complete the cutting of the concrete, and the finer particle size is required to cut the steel bar.

5: The bond composition is also different, The core requirement of the segment for stone cutting is stability, and the carcass is relatively stable. Different steel mixes have different thicknesses of steel bars, plus the different ratios of stone and cement in the concrete, resulting in two completely different paths for the diamond cutter head for cutting steel mix cutting and the stone segment.

Linxing diamond cutter head, specializing in the production of stone segment and steel mixed segment, welcome customers to come to consult.

The difference between stone cutting segment and concrete cutting segment

Publish date:2022-07-14 15:15:16 Article From:Linsing Diamond Tools Clicks: