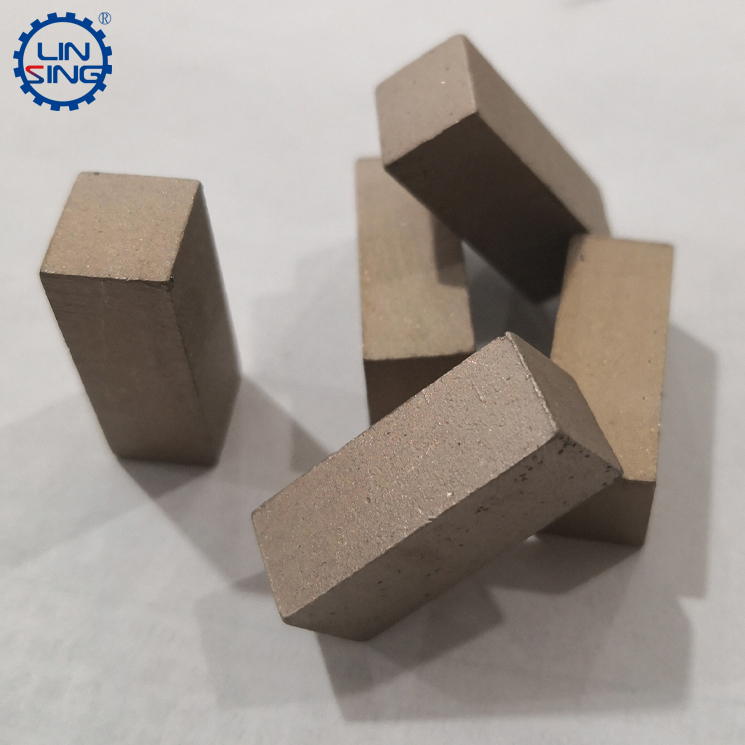

The diamond segment is sintered by both diamond and matrix bond. The material of the matrix bond is different, resulting in the diamond segment being divided into four common types: iron-based, copper-based, cobalt-based and silicon carbide-based. Types of head bonding agents, copper-based products are yellowish in color, and silicon carbide-based products are not widely used. This article will not discuss them. Only iron-based segments and cobalt-based segments with similar carcass colors are compared.

What is an iron-based segment? During the sintering process of the diamond segment, various metal powders are mixed. If the metal powder contains a lot of iron powder, then this type of bit can be called an iron-based bit. In the same way, the cobalt-based segment is a diamond segment with a large content of cobalt powder during the sintering process of the segment. So the question is, what kind of iron-based segment contains cobalt powder? Or does the cobalt-based segment contain iron powder? In fact, the iron-based segment can contain a small amount of cobalt powder, and some iron powder will also be added to the cobalt-based segment. The main reason is that iron and cobalt are elements that are compatible with diamond. They and copper, The alloy formed by the tin element can greatly increase the strength of the bond of the diamond tool bit, thereby forming a tighter material structure, thereby making the tool bit more abrasive.

What are the characteristics of iron-based segments? First of all, iron-based segments contain high iron elements, and iron powder is the most common metal in nature, so the price is much cheaper than other powders. The low price of raw materials brings about the lower overall price of iron-based diamond segments. . In terms of performance, the iron-based diamond segment has a very high hardness and a high wear resistance. Such a segment is suitable for cutting extremely hard stone or strong abrasive stones, such as granite, quartz stone, and sandstone. For stone, it is very suitable to cut with iron-based segment.

However, iron-based segments also have disadvantages. For example, the abrasiveness is too strong, when cutting soft stones or stones that are not very abrasive, it is easy to have poor cutting edges, flattened segments, and rounded diamonds. In addition, the iron-based segment uses a large amount of iron powder, so it is easy to oxidize, and the rust is easy to contaminate the slate. Therefore, the segment is more suitable for continuous cutting and quick consumption.

The cobalt-based segment is completely different. The cobalt-based segment is divided into low-cobalt-based diamond segment (20-50% cobalt powder content) and high-cobalt-based diamond segment (cobalt powder content 50%) according to the proportion of cobalt powder formula. %-70%) and full cobalt-based diamond segment (cobalt powder content 70%-90%), cobalt powder and diamond have a strong fusion, in terms of holding power, greatly improving the physical and chemical holding power of diamond, The segment with more cobalt powder has higher holding power.

However, the strength of the cobalt-based diamond segment itself is not high. The cobalt-based matrix consumes extremely fast in the process of cutting the stone with high abrasiveness. On the contrary, it does not perform as well as the iron-based segment. Therefore, the current cobalt-based segment is mainly used for Cutting marble, limestone, travertine and other soft stones.

Of course, cobalt-based segments also have disadvantages. For example, due to the high price of cobalt powder, cobalt-based segments are often several times or even dozens of times more expensive than iron-based segments. In addition, the process difficulty of cobalt-based segments is higher than that of iron-based cutters. The current technology is still at the extreme of confidentiality, especially for all-cobalt segment products, and there are very few manufacturers that can produce it. Therefore, the price of all-cobalt segments is on the high side.

The difference between iron-based and cobalt-based diamond segment

Publish date:2022-07-12 19:15:51 Article From:Linsing Diamond Tools Clicks: