Except used for cutting, diamond segment is also widely used to polish stone, such as after block cutting we need to polish the slab surface, which diamond segments are widely used to polish.

The way to calibrate the slab is not the same by different stone. Let’s introduce granite slab first:

Granite cutting machine are mainly as below: granite gang saw, single blade, multiblade , multi wire saw machine and etc. Thereinto, gang saw and single blade cutter often have error nomatter large or small because of saw blade swing, such as slab of 20mm thickness which part thickness is about 21-23mm need calibrating the extra part first, in this case calibrating wheel is needed to achieve this process. There are two types of calibrating wheel, one that is called planet wheel is mill type ,which structure of the wheel is that the cutter head is welded under the disc and upper part is used to fix the disc body. The whole body is constantly grinding the stone through the lower part of the diamond segment, finally setting the stone thickness to about 20.5-21mm.

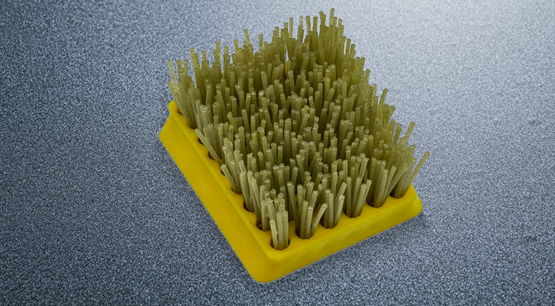

Another that design thought is from quartz calibrating wheel design is roller type, he main structure is the diamond segment structure product with lumpy side of the roller . We can make diamond segment into chip or slice, This tool is mainly used in specially designed roller calibrating machine which most isItaly equipment.

After calibrating the granite slab, there is further grinding using two tools as rough grinding. First tool is diamond fickert which consist of a large diamond segment and agglomerated fixed matrix. Diamond fickert is mainly used in fickert continuous polish machine. There are seven fickert connectors under the rotatable grinding disc and fixing diamond fickert on the grinding disc. When the machine is preparing, the working disc will automaticly grind granite stone to polish the stone. Second tool using diamond segment with welding size of 20*5*8/10mm on the disc is metal polishing machine, suitable for disc type automatic continuous polishing machine. The working principle is similar to fickert polishing machinel. Due to less contact between polished surface and stone,adding lack continuty, so its polishing effect and degree are weaker than diamond fickert mill.

After polishing by diamond segment, the granite is used resin and buff tools to further accurate grinding and polishing, finally we achieve the granite stone polishing process.

Then let’s introduce polish technology of marble slab:

Marble calibrating are mainly depending on frankfurt abransive which adopts frankfurt blank, this abrasive welds diamond segment at the bottom. Due to keep continuty of marble surface, the diamond on the surface of frankfurt rough grinding tools will adapt big size or continuous size and etc according by different condition to suit different needs. Marble calibrating adopts marble slab automatic polishing line, which main tools consist of frankfurt magnesite abrasive that I said above, frankfurt mixed abrasive, oxalic acid polishing and LUXO#.

Thereinto the first is used for rough grinding, second and third are used for accurately grinding, the last two kinds are used for marble polishing. All products are installed at the bottom of the marble millstone according to grit size. Finally marble slab are automaticly calibrated when it goes through the automatic polishing machinel.

The principle using diamond segment cutting stone is similar as polishing stone, it’s using diamond in diamond cake to polish stone, the difference is that cutting is more about keeping stone apart and polishing is more about procession of slab fine polishing. Cutting is all about efficency, polishing needs to pay attention to leveling effect of polishing, polishing degree and etc.polishing is attaching more attention on technology of diamond segment.

How does diamond segment polish the stone surface?

Publish date:2022-07-12 19:19:03 Article From:Linsing Diamond Tools Clicks: