In the process of using diamond segments, people will find that some segments have bulges in the middle of the diamond segment during the cutting process, and the two sides of the diamond segment are compared with the middle part. It seems that these parts are somewhat consumed quickly. In such a situation, since the two sides of the diamond segment are ground during the cutting process, the cutting accuracy will be greatly affected, and the following situations may also occur: 1: The gap of the stone is uneven. Since the consumption on both sides of the diamond segment is uneven, it is normal for the plate to be uneven during the cutting process.

1: The gap of the stone is uneven. Since the consumption on both sides of the diamond segment is uneven, it is normal for the plate to be uneven during the cutting process.

2: There are major failures in cutting, such as the stone cannot be cut, the saw blade is damaged during the cutting process, etc., mainly due to the slow consumption of the middle part during the cutting process of the stone, and the cutting sharpness have relative big problem. Both sides of the segment are consumed, and the matrix or diamond in the middle part is likely to have a ratio problem, and the sharpness is often not enough.

3: During the cutting process of the raised diamond segment, the cutting seam is not flat, and the saw blade will continue to work along the twisted cutting seam during the cutting process, even causes a problem with the spindle of the machine.

Therefore, under normal circumstances, in the process of using the diamond segment in the stone factory, if the middle of the diamond segment is raised, such diamond segment is often unavailable. So why does such a problem occur? There are several reasons as follows:

1: The speed of the saw blade is too fast. When the sharpness of some diamond segment is not good, this situation is especially obvious. When the linear speed of the saw blade is greatly increased, the saw blade will sway during the cutting process, and there will be obvious end jumps on the left and right sides of the diamond segment. In addition, the two sides of the diamond segment will rub against the stone or stone powder. In this case, both sides of the diamond segment will be quickly consumed.

2: The depth of the cutting depth is too large. When the sharpness of the diamond segment is not enough, the depth of the lower knife is too large. During the cutting process of the saw blade, the force received by the knife head increases, and the saw blade will have obvious radial jumps, and the matrix and the The cutter head is deformed, and the deformed cutter head and saw blade will cause the cutter head to come into contact with the stone.

3: Insufficient cooling water. When the cooling water is insufficient, a large number of quartz particles accumulate in the cutting gap. When the saw blade is cutting, the two sides of the diamond segment with insufficient chip removal capacity continue to cut these waste materials, increasing the consumption of the diamond segment. At the same time, the wear on both sides of the diamond segment is accelerated.

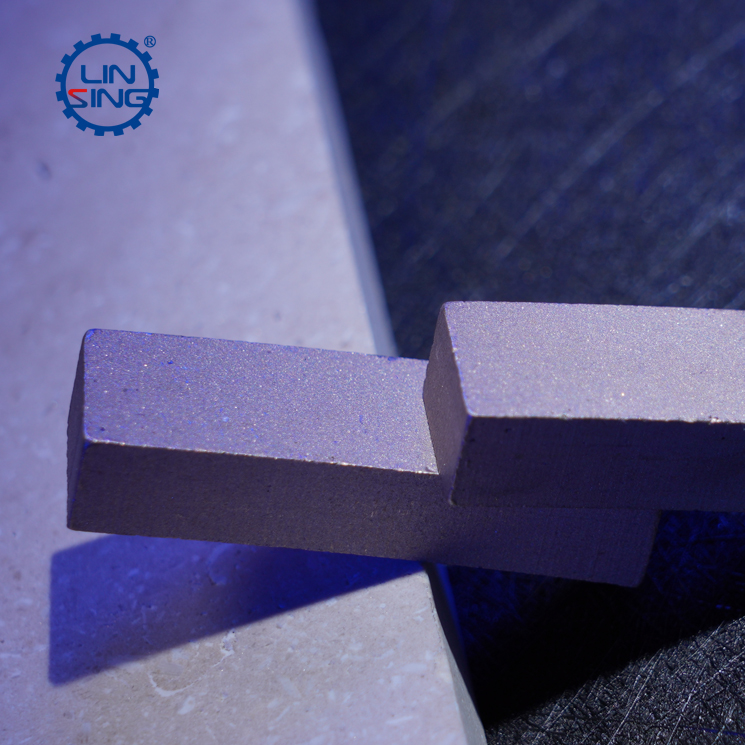

4: There is a problem with the formula of the diamond segment design. Under normal circumstances, the middle material layer and the material layers on both sides of the diamond segment are composed of different diamond ratios. Generally speaking, the ratio of the material on both sides is slightly higher than that of the middle layer material. , that is to say, the consumption of both sides of the diamond segment is faster than that of the intermediate material layer. Because the consumption of chip removal must be taken into accoun. But if the diamond ratio of the edge material of the diamond diamond segment and the diamond of the intermediate material layer is wrong. The situation of this convexity in the middle of the diamond segment will occur. So how to solve such a problem?

So how to solve such a problem?

In fact, if the middle convex diamond segment is found early, it is best to adjust the cutting line speed, appropriately reduce the cutting depth, and increase the water supply to solve the problem. If such a problem occurs after the cutter head has been cut in the later stage, it is recommended to re-weld the new diamond segment. During the process of using the new diamond segment, workers in stone factory can always observe the cutting state of the diamond segment, make a detailed record of the actual consumption of the intermediate material, and record the knife depth and line speed at the same time so as to better feedback to the manufacturer problem and solve the problem in a timely manner and further reduce the probability of this situation, thereby improving production efficiency and reducing production costs.

Reasons and solutions for the convexity in the middle of the diamond segment

Publish date:2022-10-15 11:04:56 Article From:LINSING diamond tools Clicks:

Diamond Segment For Granite Cutting

Diamond Segment For Gang Saw

Diamond Segment For Sandstone Cutting

Diamond Horizontal Blade For Marble

Vacuum Brazed Diamond Saw Blade

Related News

- Several aspects to consider in diamond segment customization

- Diamond segment on diamond requirements

- Liquid phase sintering and solid phase sintering of diamond segment

- 70% diamond segment factory planning adjust price due to diamond powder price is increasing

- HOW TO CHOOSE THE BEST SUITABLE DIAMOND SEGMENTS

Related Knowledge

- Influence Of Diamond Particle Size On Saw Blade Performance

- Relationship Between Tooth Width Of Diamond Saw Blade And Blank Blade Thickness

- Installation Methods Of Diamond Saw Blade

- Introduction Of Common Parameters Of Diamond Saw Blade

- The Relationship Between Wear Resistance And Efficiency Of Diamond Saw Blades