During the actual sawing process of the diamond saw blade, the blade segment tends to become blunt as it is cut, just like the kitchen knife we use every day. So why is this happening? There are mainly the following reasons: 1.Inhomogeneous mixing of diamond and metal powder

1.Inhomogeneous mixing of diamond and metal powder

During the production process, if the segment is unevenly mixed during the production process, and the diamond and metal powder are not mixed uniformly, it is easy to cause the segment to become blunt. This kind of bluntness often exists in the whole cutting process. The specific performance is that the cutting segment shows cutting power, sharp sound, and stone shaking during the process of cutting stone. During the shutdown inspection, it will be found that the surface of the segment is partially ground. Some segments do not have diamonds or rarely have diamond tailings, which are mostly due to production problems. If you encounter such a situation, you need to contact the manufacturer to make a product claim

Production problems are also reflected in the sintering of the segment, such as sintering temperature, sintering pressure, heating and pressing time, etc. We classify these situations into the second point for explanation.

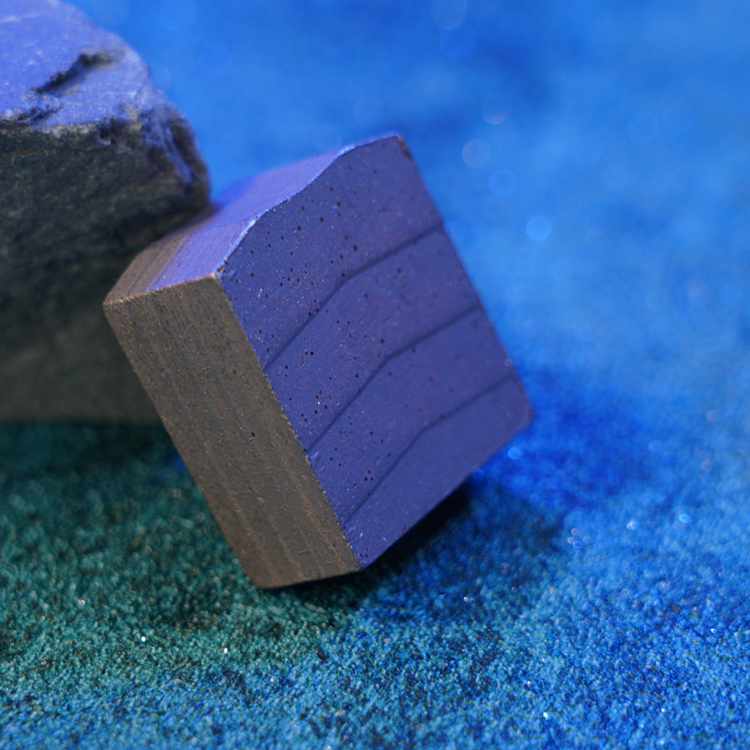

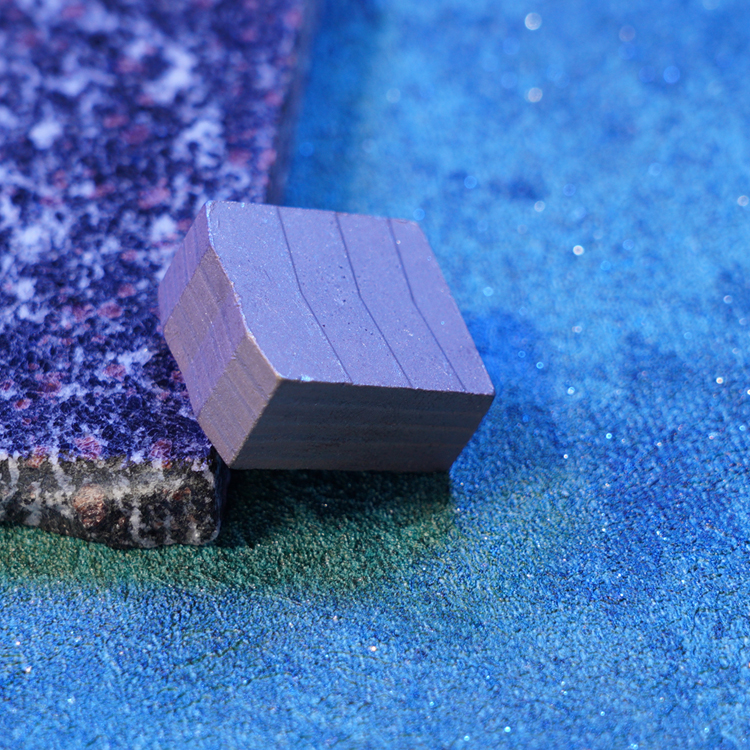

2. The wear resistance of the segment is too high

If the saw blade is used to cut stone with high abrasiveness, the metal bond and diamond of the segment will be consumed quickly. So in most cases, the segment will not be blunt. But when the segment cuts soft stone, the metal bond can hardly be consumed, and the rate of diamond consumption is even higher than that of the carcass, so the segment is ground flat. During the shutdown inspection process, it will be found that the segment of the entire saw blade is ground flat, and the segment does not come out of the edge or the edge is ground out. In this case, the second sharpening of the segment can be carried out, such as using refractory bricks to re-extrude the diamond in the segment, and the segment after the blade can no longer cut soft stone alone. After cutting soft stone for a period of time, it is necessary to cut some refractory bricks for re-cutting of the segment before continuing to use it.

3. The speed of the saw blade is too fast

In the process of cutting stone with diamond saw blade, if the speed of the saw blade is too high, the friction time between the segment and the stone during the cutting process will be reduced, and the residence time of the cutting surface will be reduced. The friction process of the segment is not sufficient and complete, but the diamond is broken due to such a high rotational speed. This situation is almost unavoidable, and a large amount of diamonds are broken due to the excessive speed of the saw blade when it should not be broken. While crushing, the cutting distance is reduced, and after the cutting distance is reduced, the cutting capacity also decreases. If this goes on for a long time, the segment will become obviously blunt.

The bluntness of the segment caused by this reason is a process of gradually reducing the sharpness of the saw blade. The specific performance is that the diamond edge of the segment is getting worse and worse, and even some grinding conditions appear. The solution is that appropriately reducing the sawing line speed and appropriately increasing the cutting depth can significantly improve this problem.

4.Different diamond quality grades

Diamonds are also very important for this reason. Diamonds are divided into grades, strengths, and particle sizes. The higher the diamond grade, the stronger the critical crushing capacity. In the process of use, the less consumption in the sawing process, the stronger the cutting ability. Diamonds with weaker grades are the exact opposite, and are prone to excessive fragmentation. Often diamonds are broken before they are consumed, and the location and angle of the breakage are very particular. The strength of diamond is also a very important factor in the design of the segment. When cutting hard stones, diamonds with higher hardness should be used as much as possible. This will keep the diamond and stone in a reasonable and synchronized crushing relationship. As for the particle size, it is also a way to maintain the cutting spacing. In general, there are many reasons why diamond segments are easy to cut and dull. There are diamond reasons, metal bond reasons, and operational problems. Therefore, in the actual application process, we must first find out the accurate and reasonable reasons, conduct analysis and judgment, and finally find a reasonable solution, which is the correct solution.

In general, there are many reasons why diamond segments are easy to cut and dull. There are diamond reasons, metal bond reasons, and operational problems. Therefore, in the actual application process, we must first find out the accurate and reasonable reasons, conduct analysis and judgment, and finally find a reasonable solution, which is the correct solution.

Reasons and solutions for diamond segments to be blunt

Publish date:2022-12-19 17:38:46 Article From:LINSING diamond tools Clicks:

Diamond Segment For Granite Cutting

Diamond Segment For Gang Saw

Diamond Segment For Sandstone Cutting

Diamond Horizontal Blade For Marble

Vacuum Brazed Diamond Saw Blade

Related News

- Several aspects to consider in diamond segment customization

- Diamond segment on diamond requirements

- Liquid phase sintering and solid phase sintering of diamond segment

- 70% diamond segment factory planning adjust price due to diamond powder price is increasing

- HOW TO CHOOSE THE BEST SUITABLE DIAMOND SEGMENTS

Related Knowledge

- Influence Of Diamond Particle Size On Saw Blade Performance

- Relationship Between Tooth Width Of Diamond Saw Blade And Blank Blade Thickness

- Installation Methods Of Diamond Saw Blade

- Introduction Of Common Parameters Of Diamond Saw Blade

- The Relationship Between Wear Resistance And Efficiency Of Diamond Saw Blades