The hardness and strength of the diamond segments are not the same concepts. There is a separate introduction about these two definitions as follows:

The hardness of the diamond segments:

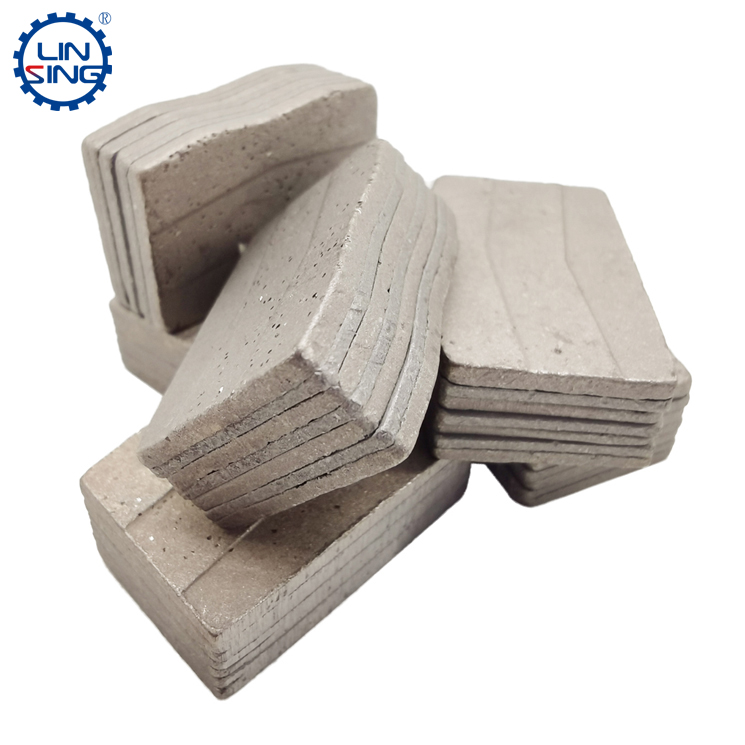

The diamond segment is refer to diamond powder with metal bond powder formed after through mix, cold forming, hot sintering, and cooling and demolding. The hardness of the segment, in simple terms, according to the hardness detection method, the Mohs scale of mineral hardness of diamond is defined as 10. The depth of scratches caused by diamonds and other objects is the Mohs hardness value. The Mohs hardness of marble is mostly around 4-6, while the Mohs hardness of granite is mostly 6-8. What is the Mohs scale of mineral hardness for diamond segments? Since the segment is a hybrid diamond segment, it is generally divided into two statements. If the calculation is based on the whole diamond segment, the hardness of the diamond segment is 10 by default because the segment contains a large amount of diamond powder. However, some people use separate calculation methods for calculation.For example, the Mohs hardness of the matrix in the segment is 6-9.5, while the Mohs hardness of diamond is 10.

The significance of measuring the hardness of the diamond segment is to better cut the stone. Generally speaking, stone cutting is all about grinding it with a harder segment. "The stone of the mountain can attack jade" is the truth. However, the hardness of the bond should not be too high, otherwise, the slow consumption of the bond will cause the diamond to grind flat, so that the stone cannot be cut. It can be said that the hardness of the diamond matrix is an extremely important reference factor in the production process of the segment.

The strength of the diamond segment:

The strength of the diamond segment is a manifestation of comprehensive performance: There are mainly the following four types, namely flexural strength, impact strength, yield critical strength, wear resistance, etc.

Flexural strength: During the cutting process of the diamond segment, if the cutting is twisted, it is necessary to check whether the cutter head can maintain a straight shape instead of a curved state. Take a common example. During the cutting process of the segment, if the segment encounters the hard part inside the stone, at this time, if the bending resistance of the segment is not enough, it is easy for the segment to bend and the cutting to be offset under high strength. The serious consequence is the distortion of the saw blade base.

Impact strength: It refers to the impact resistance of the segment under a certain impact force. The higher the impact strength, the less chance the segment will be deformed. This is often the case when cutting hard stone. The impact resistance of the segment is not high, and the segment is squeezed into one piece, which not only causes the cutting to be unable to continue, but also damages the stone surface and even cuts the stone.

Yield Strength: It is also a critical value, which represents how much force the segment will experience irreversible deformation, such as bending, such as height shortening.

Wear resistance: Wear resistance is an extremely important indicator of the life of the segment. The higher the wear resistance, the stronger the grinding ability of the segment.

Overview of Hardness and Strength of Diamond Segments

Publish date:2022-07-14 15:03:45 Article From:Linsing Diamond Tools Clicks: