Quarry segment is a cutting tool used in mining, exploiting and quarry industries. Its main function is to cut and separate rocks in mines and quarrying sites to obtain the required stones and ores. Quarry segment are usually made of diamond, carbide and other materials, and their structures and shapes vary according to different mining needs. For example, the segment used for the mining of large stones in quarries are usually large and strong in structure, while in coal mines, some slender segment are required to cut out the ore smoothly. Quarry segment are indispensable tools in mining production, and their quality and performance have an important impact on mining efficiency and cost control. The welding of mining segment is difficult, mainly due to the complexity of its material properties and use environment.

The welding of mining segment is difficult, mainly due to the complexity of its material properties and use environment.

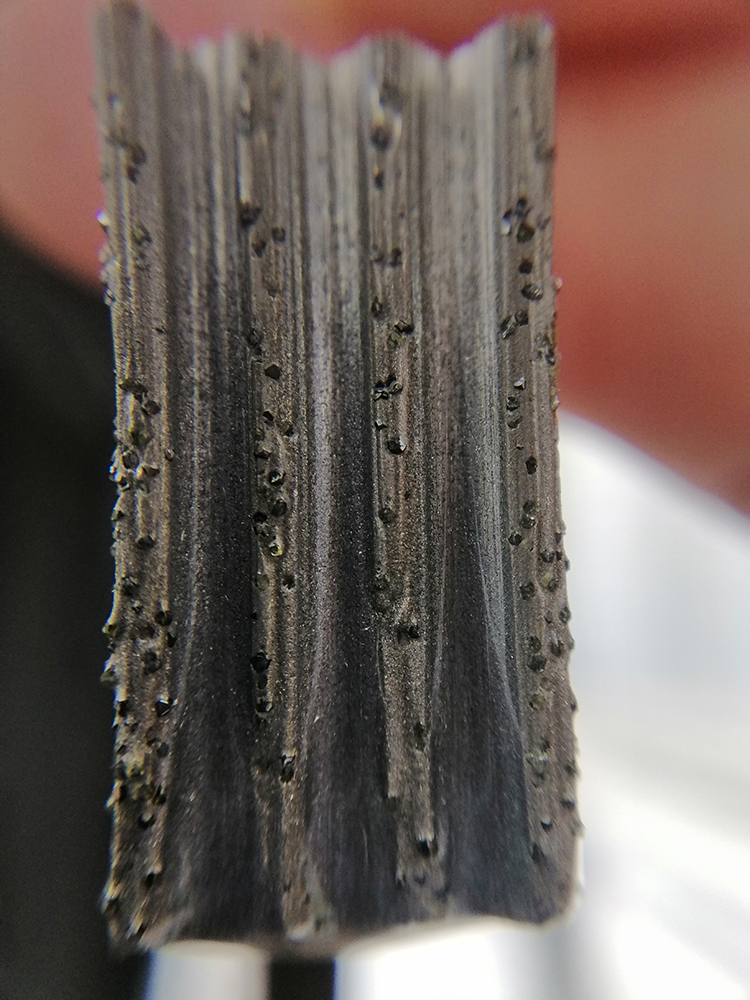

Mining segment can be used in harsh environments, such as high temperature, high pressure, high humidity, high corrosion, etc., and also need to have sufficient wear resistance and impact resistance. Therefore, its materials are usually made of high-hardness, high-strength diamond or other superhard materials. These materials are relatively difficult to process and require special processes and equipment to manufacture.

During the welding process, due to the complex shape of the mining segment, multiple segment parts need to be spliced, so it is necessary to master the welding skills to ensure the welding quality. In addition, the material hardness of the mining segment is relatively high, and the welding process needs to be carried out by high temperature and high pressure, which also puts forward certain requirements for equipment and technology.

The following is the process of general high frequency welding and arc welding quarry segment:

1. Preparation:first of all, the diamond blade and steel substrate to be welded should be cleaned and ground to ensure that the welding surface is free of impurities and oxide layers, and at the same time, appropriate welding materials and welding tools should be selected.

2. Clamping and positioning: put the diamond segment and the blank blade into the welding fixture, and perform positioning to ensure that the position and angle of the two are correct.

3. Spot welding fixation: spot welding is performed at the position to be welded to fix the relative position of the diamond segment and the blank blade.

4. Formal welding: heat the welding solder or electrode to the welding area to make it reach the melting point, and fuse the diamond segment and the blank blade in the molten state.

5. Cooling and shaping: after the welding is completed, the welding area needs to be cooled, shaped and polished to ensure that the surface of the welded segment is smooth and flat, free of air holes and cracks.

6. Inspection and testing: finally, inspect and test the welded quarry segment to ensure that its welding quality and performance meet the requirements. It should be noted that the welding process of the quarry segment needs to be strictly controlled and operated to avoid excessive heat and stress, which can cause deformation or cracking of the diamond segment or blank blade.

It should be noted that the welding process of the quarry segment needs to be strictly controlled and operated to avoid excessive heat and stress, which can cause deformation or cracking of the diamond segment or blank blade.

It should be noted that during the welding process, the height of the welding frame needs to be adjusted. It is best to build a two-story platform with a height of more than 2.5 meters to facilitate welding of circular saw blades of various diameters.

How to weld the quarry segment

Publish date:2023-04-11 21:34:44 Article From:Linsing diamond tools Clicks: