The usual way of welding diamond segment is high frequency welding, and it’s different way cold welding machine, the mainly reason is due to the welding temperatures and welding ways of cold welding machine can not reach the process requirement of diamond segment welding, so far the cold welding machine can not use for diamond segment welding.

In this article will introduce the difference between cold welding machine and high frequency welding machine from seven ways and let people get great understand why the cold welding machine can not apply in the diamond segment welding.

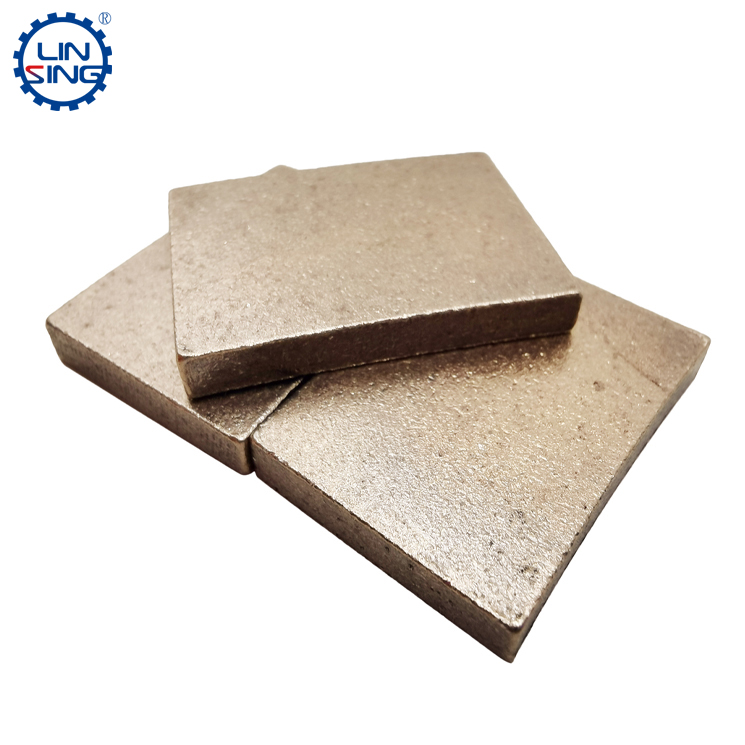

1: Cold welding machine is the machinery that can be repaired for any metal materials. The metal material can be repaired is usually single, such as: copper, iron,aluminum, tin ect. After set the temperatures of machine, the process of repaired metal materials is very simple. But diamond segment is the composite material and made by different metal will lead the cold welding machine can not adjust the welding temperatures very accuracy. So it can not made the segment with blank blade of saw blade to welding together very well.

2: Cold welding is the way like local heating, and this way usually only works for the outside and side of diamond segment and saw blade can not get into the center of the inside part, it will cause there will be a huge gap between segment and blank blade.

3: The cold welding machine uses the electric shock rod as the welding material. Although this material can meet the ordinary welding requirements, these welding materials are still too soft for the segment that has great demands on the force, and the welding firmness is also too soft. Insufficient, so this material does not have much benefit for the welding of diamond bits.

4: Cold welders often use surfacing to increase winter vacation strength, but for diamond segment that cut hard stone, this auxiliary gain is useless, or even better than this gain, making the entire welding process more responsible , so as to increase the difficulty of tool head welding.

5: Of course, compared with laser welding, cold welding can save argon gas, but for high-frequency welding that does not require the use of rare gases, the cost of laser welding is too high, and the repeatability and utilization rate of saw blades The low disadvantage makes it not have a price advantage.

6: Cold welding uses a precise electronic control system for system deployment, and high-frequency welding is nothing more than controlling the welding temperature and welding time of the cutter head. Therefore, in terms of operability, high-frequency welding is undoubtedly simpler and the operation is also easier. More convenient.

7: Because the cold welding machine is mostly used for good welding processing between the same materials, it cannot solve the welding processing of dissimilar material parts, so it is not recommended to use this method to weld the segment.

Totally, Cold welding machine is not a very good processing machine in the process of segment welding. At present, high frequency welding machine and laser welding machine are the best segment welding machines. Of course, the future does not rule out the functions that the cold press welding machine can have after the technological innovation.

Does the diamond segment can be weld by cold welding machine?

Publish date:2022-07-13 17:16:18 Article From:Linxing Diamond Tools Clicks: