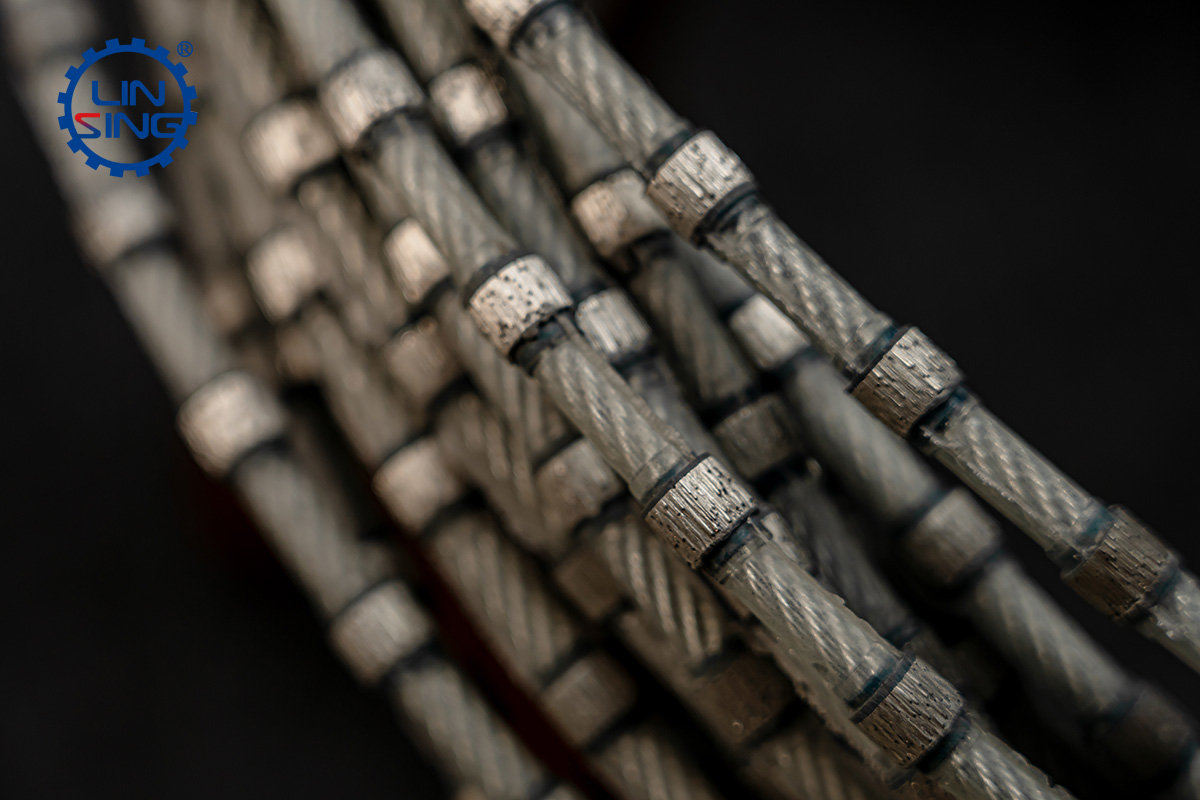

Diamond wire saws need cold pressing mainly to achieve the consolidation and bonding of diamond particles and metal powder. The cold pressing process can combine diamond particles and metal powder closely together under high pressure at normal temperature to form a strong blade or wire saw structure.

Here are the main reasons and benefits of diamond wire saw cold pressing:

Bonding strength: The cold pressing process can form a high-strength bond between diamond particles and metal powder. By applying high pressure, the bonded contact area between diamond particles and metal powder is increased, and the gaps between particles are filled, thus improving the overall strength and stability of the wire saw.

Uniform density: The cold pressing process can realize the uniform distribution and close packing of diamond particles and metal powder. By precisely controlling the cold pressing parameters, the diamond particles and metal powder can be evenly distributed in the wire saw, avoiding the gaps and inhomogeneities between the particles, and improving the overall density and firmness of the wire saw.

High hardness and wear resistance: The cold pressing process can combine diamond particles with metal powder to form a high hardness wire saw. Diamond is one of the hardest substances known at present. Through cold pressing and consolidation, the hardness and wear resistance of diamond particles can be transferred to the whole wire saw structure, making it have excellent cutting and wear resistance.

The cold pressing process of diamond wire saw can be divided into the following steps:

Prepare diamond particles and metal powder: choose suitable diamond particles and metal powder, usually the particle size of diamond particles and metal powder should match to ensure better bonding effect.

Mixing diamond particles and metal powder: Mix diamond particles and metal powder evenly in a certain proportion to ensure that the diamond particles can be evenly dispersed in the metal powder for uniform consolidation in the subsequent cold pressing process.

Placing the mixture: Place the mixed diamond particles and metal powder in the mold of the cold pressing equipment to ensure that the mixture is evenly distributed.

Apply high pressure: Apply high pressure through cold pressing equipment to cold press and consolidate the mixture in the mold. The size of the pressure needs to be adjusted according to the specific material and process requirements to ensure the tight combination of diamond particles and metal powder.

Cold pressure consolidation: keep a certain pressure and time, let the mixture consolidate into a strong wire saw under the action of high pressure. The bond between the diamond particles and the metal powder becomes tighter during this process.

Subsequent processing: The wire saw after cold pressing and consolidation needs subsequent processing, such as sintering, polishing and other processes, to further improve its quality and performance.

It should be noted that the pressure, time, temperature and other parameters in the cold pressing process need to be adjusted according to the specific material and process requirements to obtain the best cold pressing effect. In addition, it is necessary to pay attention to safe operation during the cold pressing process to ensure the safety of operators.

All in all, the cold pressing process of diamond wire saw tightly consolidates diamond particles and metal powder by applying high pressure to form a strong wire saw structure to obtain cutting tools with high strength, uniform distribution, high hardness and wear resistance.