About diamond tools, many people don't know much about them, In fact, diamond tools refer to diamond (synthetic diamond) as the cutting material, with the help of some binders or auxiliary materials and matrix materials, It is mainly used for cutting tools for processing hard materials such as stone, ceramics, glass, and reinforced concrete.

To explain diamond tools, we must start with diamonds. Diamonds are commonly known as diamonds, also known as "diamond diamonds". The ancients said: "If you don't have a diamond, don't work with porcelain", which is the truth that diamonds are very hard. Diamond is gradually formed from carbon through high temperature and high pressure. Most of the diamonds used in diamond tools are processed by people through high temperature and high pressure equipment. In terms of particle size, according to different diamond particle sizes, it is divided into 16-3000# diamond particles with different particle sizes.

In addition to diamond, diamond tools have some powders, some are metal powders, some are non-metallic powders, some are alloy powders, and some are compounds. All in all, there are many different types of diamond tools, and the difference between the types lies in the different scenarios used. For example, diamond tools for cutting marble and diamond tools for grinding marble have different usages, and different usages determine the ratio of metal powders for diamond tools. For example, the resin bra used for fine grinding granite is made of resin and diamond powder combined. Of course, in order to better increase the cutting and grinding performance of diamond, composite diamond materials such as PCD or PDC are made by secondary pressure, which has also been popularized and applied. More possibilities for the development and design of diamond tools.

Therefore, in simple terms, a diamond tool is a special composite material made by mixing diamond particles with a metal, resin, brazing filler metal and other binding agents according to a certain process. Due to the development of the building materials industry, the application of diamond tools has become more and more extensive. The application of diamond tools is also becoming more and more extensive, and there are higher requirements for the production of tools in terms of economy and performance. The key to improving tool performance is the wear resistance of the product (that is, the life of the product), while maintaining sharpness (that is, cutting efficiency)

The components of diamond tools generally consist of two to three parts:

The first part: diamond grinding segments, such as segments, grinding disc grinding segments, resin grinding blocks, etc., which is the main processing part.

The second part: the base part, that is, the base of the saw blade, the disc of the grinding disc, the wire rope of the diamond wire saw and the connecting parts, etc.

Diamond tools are divided according to their uses: drills, saw blades, and grinding, that is, "drilling, cutting, and grinding" tools.

According to the production process: sintering, welding, electroplating products, etc.

Divided by bond: metal bond, resin bond, ceramic bond, etc.

The concept of concentration of diamond tools: define that the concentration of diamond in the matrix is 100% when the volume ratio is 25%. Concentration is one of the important characteristics of diamond tools, which has a great influence on the efficiency, life and processing effect of the tool. Generally, the higher the diamond concentration, the more diamond particles per unit working layer area. The force of each abrasive grain is small, the depth of cutting into the workpiece is small, the diamond is not easy to break and fall off, but it is easy to be ground and polished, and the macroscopic performance is low efficiency and long life. The diamond concentration is low, each abrasive grain has a larger cutting pressure, the cutting depth is deep, the diamond is easy to break and fall off, and the tool performance is high efficiency and low life.

Usually, the diamond concentration of the sawing tool should be selected at 10%~45%; Drilling tools and sintered metal bond diamond abrasives should choose 50%~125% concentration; The concentration of resin diamond abrasives should be more than 50%~100%; Select 75%~150% concentration for ceramic diamond abrasive tools; 200% concentration for electroplating and brazing diamond tools.

There is still a lot of knowledge about diamond tools, such as production, such as welding, etc. Other knowledge is introduced in the company's other consultations, so I won't go into details here.

Basic Knowledge Of Diamond Tools

Publish date:2022-07-19 11:25:01 Article From:Linxing Diamond Tools Clicks:

Vacuum Brazed Diamond Saw Blade

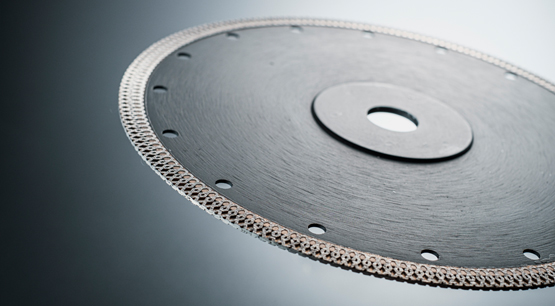

Continuous Rim Diamond Cutting Disc

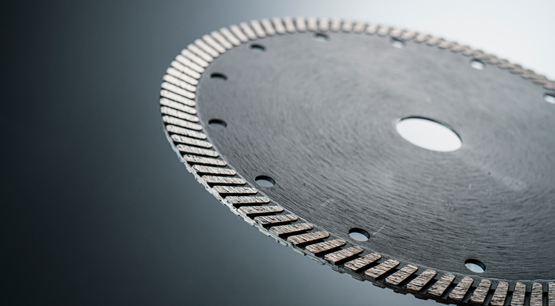

Turbo Cutting Disc

X Mesh Turbo Cutting Disc

Turbo Type Protection Teeth Cutting Disc

Related News

- Commonly used segment styles for granite 300-1000mm saw blades

- How to choose diamond circular saw blade and diamond segments?

- Introduction of ceramic saw blades and diamond segments used

- The difference between saw blade diamond segment and other diamond segment

- How to solder the diamond segment on the saw blade?

Related Knowledge

Brazed diamond cutting blade is a very special diamond tool This saw blade uses vacuum brazing to fix the diamond on the saw blade substrate The entire saw blade has a simple structure and less sintering and welding processes, the stability is higher This article mainly introduces the advantages and disadvantages of brazed diamond cutting discs

07/04

2022

Why Are Super Large Diameter Diamond Saw Blades Not Used For Block Cutting?

Diamond saw blades have great application differences according to the change in size For example, the size of the saw blade for cutting blocks is mainly concentrated in 900-3500mm Why aren t super large diameter saw blades used for block cutting? What s the difficulty? Can it be solved? These are the questions to be discussed in this article

07/04

2022