Since ancient, natural stone is the most commonly used construction material. With the development of the technology and fast improvement of the stone cutting tools’ sharpness and cutting performance, the stone decoration plate, line, window decoration, and door decoration such material are extensively used. The quality of the cutting directly decides the beauty of the end product. And the stone cutting diamond segment becomes the important deciding factor to the stone quality.

It is very complex of the diamond cutting segment manufacturing technology development direction. Because the manufacturing technology diversification and process ring node vary, it will cause the diamond segment technology large improvement. Lots of tests discovered that maybe humans still have not grasped the secret of the fasting and stable cutting stone, and still be in the exploration period at the moment. However, the stone cutting technology innovation has been experienced earth-shaking changes. This article will make an introduction from 3 different technology improvements to make everyone better know about the stone cutting diamond segment manufacturing technology improvement.

First, the sintering temperature control technology improvement. In the diamond segment sintering process, it needs to energize the graphite mold. High resistant mold would begin to rapidly heat up through the graphite mold’s strong current positive and negative electrodes. When the temperature rises to a certain level, it will begin to keep the insulation stage. And this temperature is for diamond segment sintering.

In the beginning, the sintering machines’ sintering temperature is according to the people’s sintering habits. Very likely the sintering machines’ sintering temperature are all keeping a certain temperature. However, people discovered that segments are sintered in this way will cause the mental molecules and atoms not best for combination. The too high temperature will carbonize the diamond which will cause the segment cutting performance reduce. However, if the temperature is too lower, the metal can’t be better sintering, then the metal molecules and atoms can’t be better combined. And it will not produce a suitable alloy, then eventually cause the products’ compression resistance, ductility, hardness, and abrasiveness to be smaller than the expected situation.

But if we can set up different temperatures for different segments’ formulas. Second, analyze for full segment expected reaching the ideal sintering effect in the formula design beginning. Then, make a preliminary judgment about the metal molecules and atoms’ motion trajectory and activity trajectory. And combining the diamond suitable carbonize reaction, eventually will obtain the diamond sintering temperature in the formula design process. At this sintering temperature will constantly make a few adjustments in the long term research and test, eventually get the temperature which is the result of modern diamond segment sintering control temperature technical development.

Second, synthetic diamond segment development. Synthetic diamonds occurred in France, the USA, Germany, Italy, The United Kingdom countries, etc. In the 1980s, China started to research synthetic diamonds. After 40 years, China has held most of the market shares in the synthetic diamonds industry with product quality plus the extremely high cost-effectiveness that has completely required the diamond segments’ cutting requirements.

Synthetic diamonds’ development mainly improves from the whole structure’s hardness, impact resistance, reasonable, grit, and several aspects. At present, Zhongnan Diamond and Huanghe Whirlwind company has carried the China synthetic diamonds’ quality banner. The diamonds quality improvement also helps the diamond segment products’ quality fast improvement.

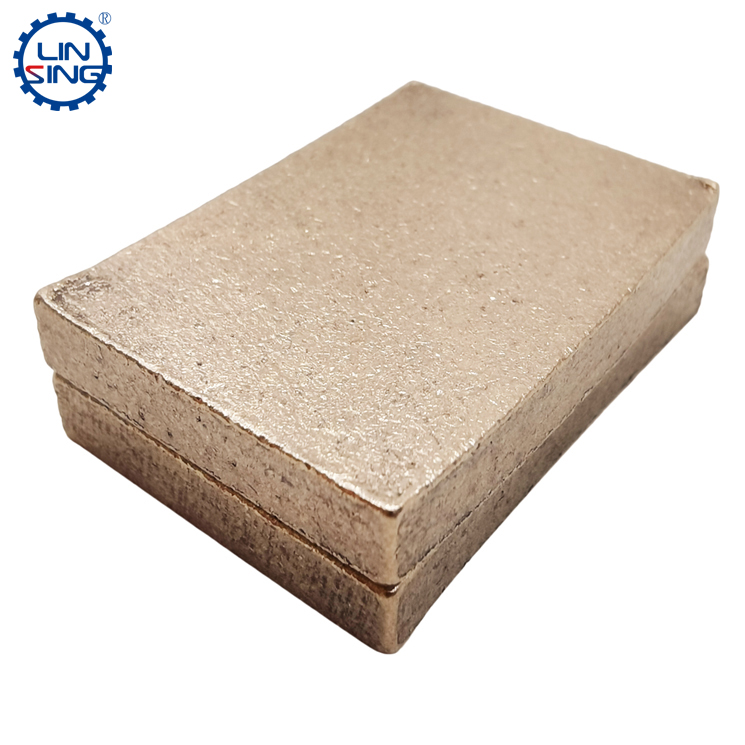

Third, the diamond segment formula and crafts’ renew is the diamond segment nucleus development. How to design the cheaper price, products’ quality more stable, longer cutting life, and higher sharpness products, the formula crafts improvement is necessary. And the crafts changes would help to solve diamond segment some problems temporarily. For example, in early people would like to use a one-piece structure, but later people discovered that such a segment has problems in chip removal and cooling. Slowly, people would like to use sandwich and layer diamond segment, but people also recovered that the layer material is to use metal sheets or powder? Then people began to research kinds of different crafts to meet different cutting requirements.

All in all, in modern society, the diamond segment development history is the people cutting stone process. And the fast development technology makes cutting stone easier and easier.

The development of the stone cutting diamond segment producing technical

Publish date:2022-07-13 16:13:22 Article From:Linsing Diamond Tools Clicks: