Slate is a type of stone with a plate-like structure that presents layers of exfoliated shapes. Early people used a wide range of slate. Especially in the application of pavement, slate is used in many places. This kind of stone can easily peel off the slate with a chisel and a hammer as long as it follows the peel-like line, thereby speeding up the molding of the stone.

Slate is a metamorphic rock, mainly composed of argillaceous, silty, and neutral limestone. In the slate found so far, there are also some iron ores or other metal ores composed of the above three materials. The color change of slate is completely determined by the impurities contained in the slate. For example, red slate has high iron content, while green slate represents copper and other metal oxides with green metal content. Most of the slate is not more than 1 meter in length and width. Generally speaking, 300*300mm slate is more common.

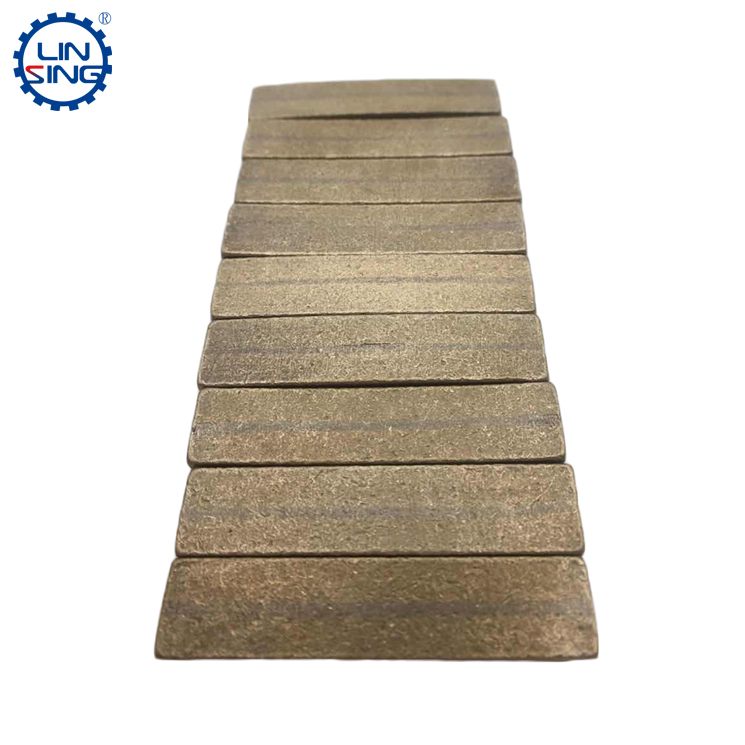

Slate material is relatively soft, generally speaking, the Mohs hardness is around 5, which is close to the hardness of limestone and soft marble. In the design process of the slate segment, this feature needs to be taken into account, so the excellent carcass segment is not suitable for cutting slate. The preliminarily designed segment carcass is a medium-soft carcass, with copper powder as the main matrix material, and a little iron powder (the content is preferably not more than 8%). Once the iron powder is excessive, the hardness of the segment carcass will be too high. However, iron powder cannot be added without adding iron powder. The matrix material without iron powder will be too soft, and the holding force and wettability of copper powder to diamond is not as good as that of iron element. For other metals, it is necessary to select nickel powder to increase ductility and bending resistance. If the segment does not consider the price factor, adding tungsten powder can form a better tungsten-copper alloy with the copper powder in the segment. It can also be used with iron, nickel and copper to produce metal alloys with strong impact resistance, and tungsten can also produce WC with diamond in the high temperature sintering process, thereby increasing the wear resistance of the segment.

In terms of other matrix binder components, in the long-term test process, if a certain amount of WC material is added, the segment is more wear-resistant. It has a longer life when cutting this kind of stone with strong wear resistance. Cobalt powder is also a metal with strong wear resistance. If a small amount of cobalt powder is added, the stability and cutting life of the segment can also be improved, and the holding force of the segment can be better, and there is less chance of falling diamonds.

In terms of diamond, due to the strong abrasiveness of slate, the degree of wear on diamond is not high, so it is more cost-effective to choose diamond of lower grade. In terms of particle size selection, it is appropriate to select some diamonds with large particles for cutting first, and then select diamonds with small particles to assist in cutting. Of course, the hardness of the carcass material should also be considered. For example, a harder carcass material, then a smaller particle size is a better choice. If the matrix material is soft, it is more advantageous to choose diamond with large particles. After the overall test, it is the best ratio to choose large particles with small particles. As for the concentration, it needs to be determined according to the actual cutting situation of the segment, and there is no uniform standard.

Most of the slate segments are used for medium diameter saw blades. The main size is about 230-450. A very small number of slate will need to be cut with a saw blade with a diameter of more than 500mm. Since the use of slate is not the same, it is mainly used for courtyard decoration, exterior walls, cultural walls, interior decoration walls, and decorating some retro floors. Most scenarios do not require too much cutting edge, so it is more common to choose a sharper blade. For example, turbo segmented saw blades, T-shaped segmented saw blades, M-shaped or V-shaped saw blades, etc., are all segment shapes that can be used for slate cutting.

Slate diamond segment

Publish date:2022-07-14 16:58:55 Article From:Linsing Diamond Tools Clicks: